A method for improving the liquid metal corrosion resistance of martensitic heat-resistant steel

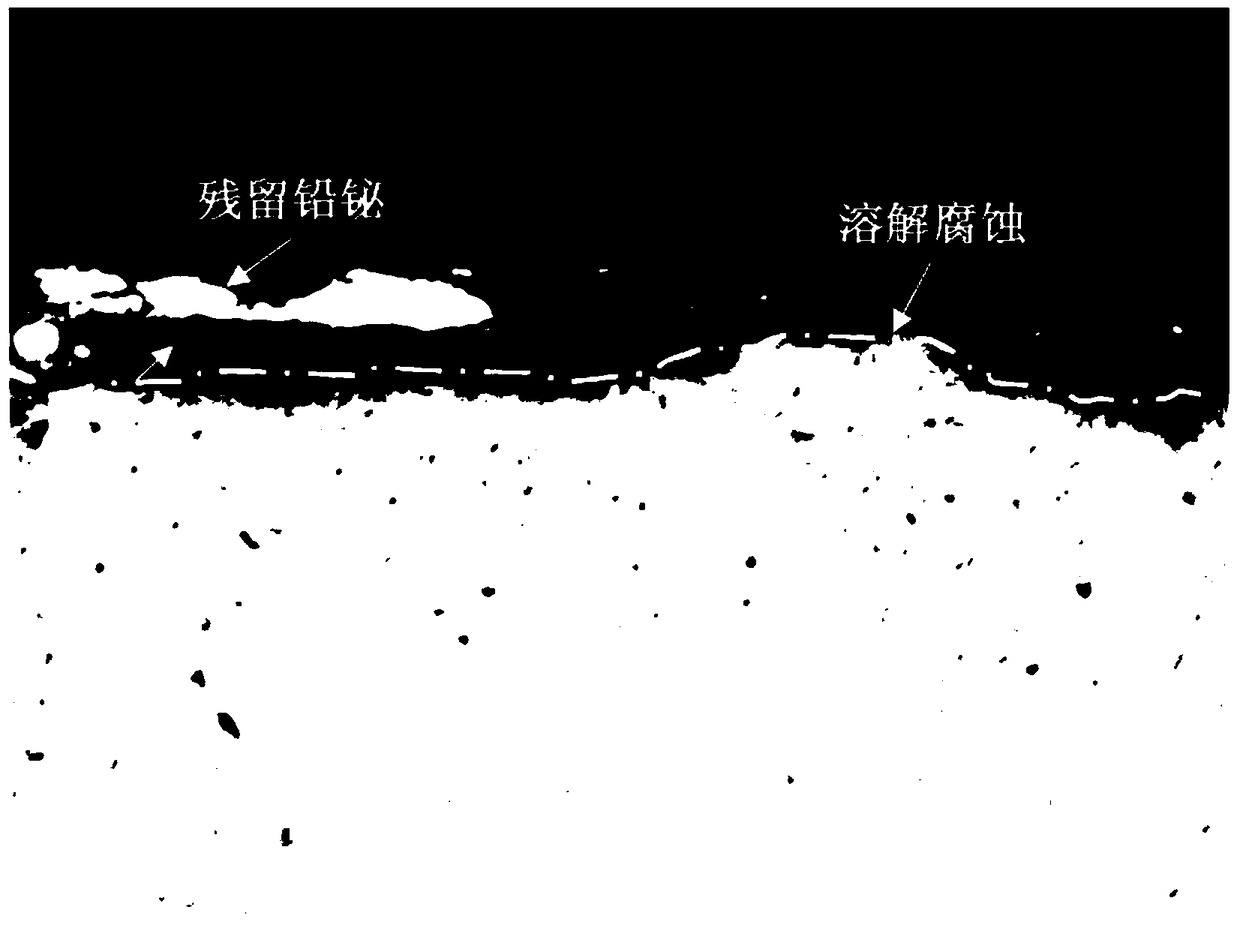

A technology of liquid metal and heat-resistant steel, which is applied in the field of metal surface treatment, can solve problems such as poor wettability and restrict the sustainable development of nuclear power, and achieve the effect of prolonging the service life and improving the corrosion resistance of liquid metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Pretreatment of the metal surface: the metal sample with a size of 15mm × 10mm × 2mm was polished step by step to No. 600 with metallographic sandpaper, and all the edges and corners were rounded, and then the metal surface was sandblasted. Ultrasonic cleaning in deionized water after metal detergent cleaning, drying;

[0021] (2) Melt the optimally designed enamel ingredients at a high temperature of 1400°C, water-cool after fully reacting, and make enamel powder through ball milling. The main component of enamel is SiO 2 : 58.26%, Al 2 o 3 : 19.2%, CaO: 3.66%, ZrO 2 : 5.29%, B 2 o 3 : 4.66%, Na 2 O: 3.40%, KNO 3 : 5.53%;

[0022] (3) Mix the enamel powder with absolute ethanol, spray it on the metal surface, and sinter it on the metal surface at 730°C±10°C to form an enamel coating of about 40 μm through curing reaction after drying.

[0023] The above metal material is martensitic heat-resistant steel, the specific chemical composition is: C: 0.25wt.%, Si...

Embodiment 2

[0026] The chemical composition of 9-12% Cr martensitic heat-resistant steel is: C: 0.19wt.%, Si: 1.05wt.%, Cr: 10.05wt.%, Mn: 1.06wt.%, W: 1.19wt.%. , Ta: 0.1wt.%, V: 0.2wt.%, Nb: 0.01wt.%, and the balance is iron. Other surface treatment processes of the metal are the same as in Example 1.

Embodiment 3

[0028] The chemical composition of 9-12% Cr martensitic heat-resistant steel is: C: 0.15wt.%, Si: 1.23wt.%, Cr: 10.46wt.%, Mn: 0.41wt.%, W: 1.5wt.%. , Ta: 0.15wt.%, V: 0.19wt.%, Nb: 0.014wt.%, and the balance is iron. The metal surface treatment process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com