Tapered protecting sleeve connected with scattered rope sling to prevent main cable from rustiness

A technology of loose cable sleeves and protective sleeves, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of loose cable sleeves with small scattered cables, easy corrosion of sub-cables, corrosion of loose cables and main cables, etc., and improve the protection effect , prevent the corrosion of the main cable and sub-cables, and facilitate the entry of sub-cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

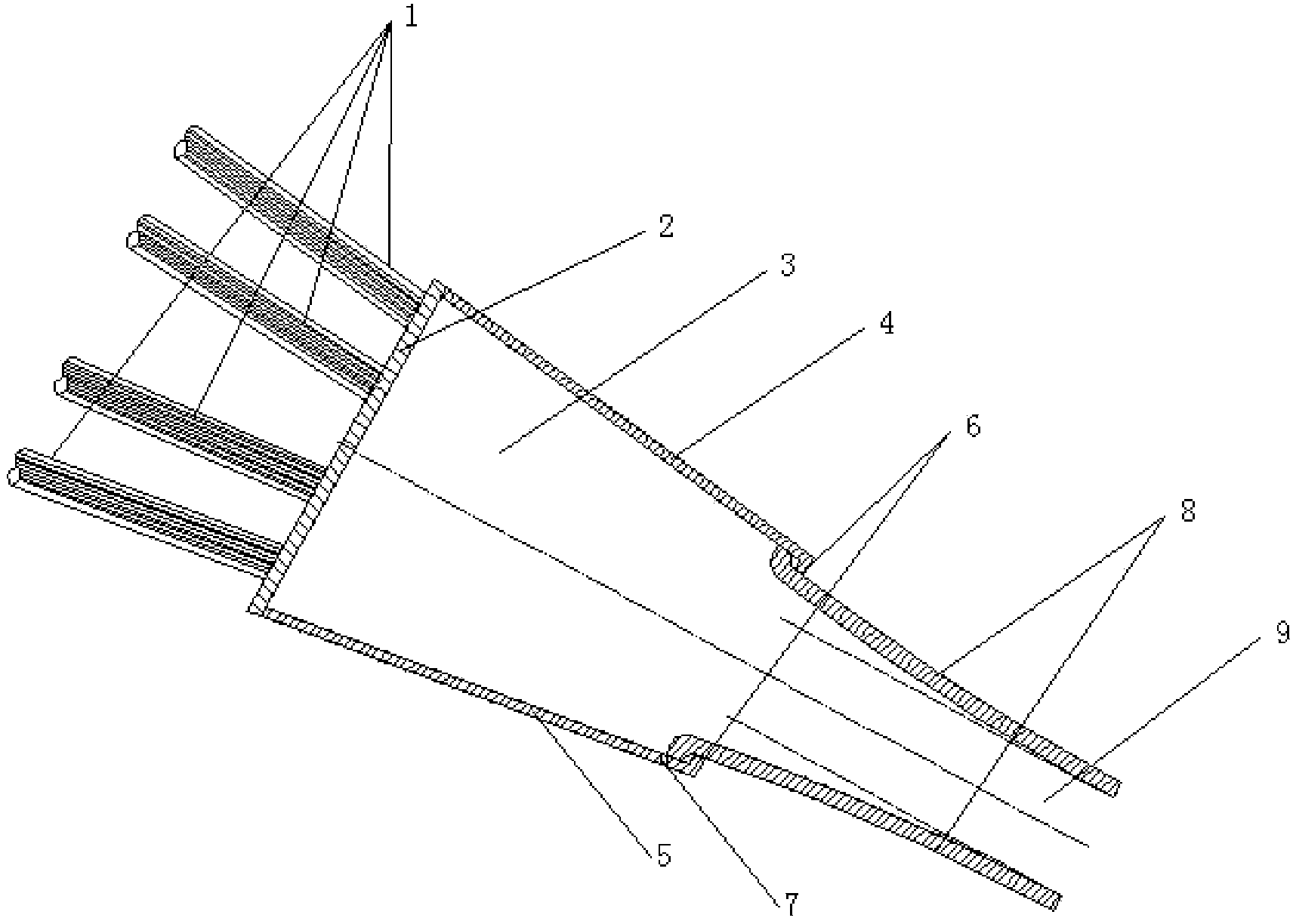

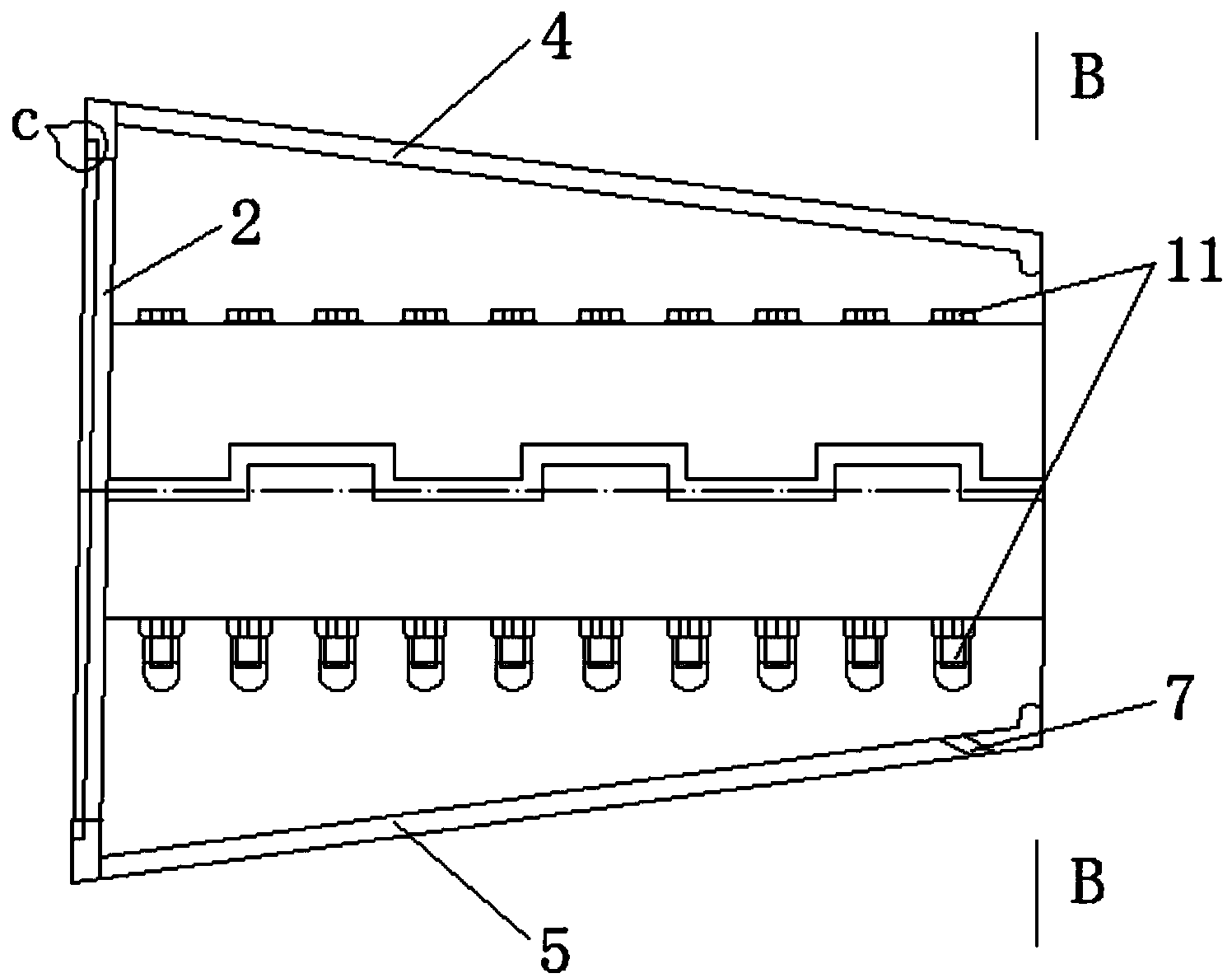

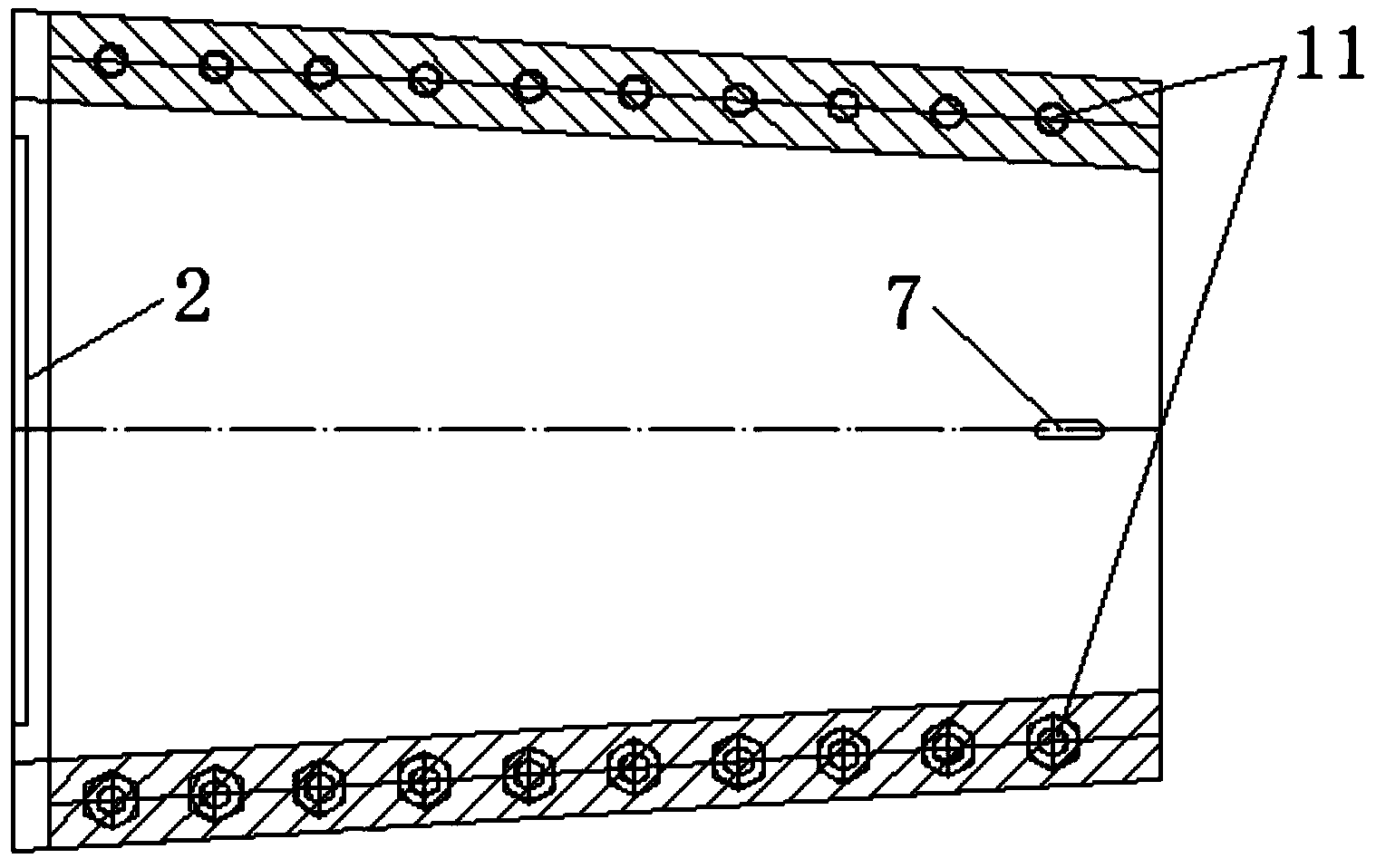

[0026] Below in conjunction with accompanying drawing, the present invention will be further described.

[0027] see Figure 1-6 , the present invention includes the upper half-conical protective steel plate 4 and the lower semi-conical protective steel plate 5 that can be spliced and fixed into a cone, and the bottom of the tip center of the lower semi-conical protective steel plate 5 is provided with a drainage hole 7; The protective steel plate 4 and the lower semi-conical protective steel plate 5 are fixed and welded by several connecting bolts 11. The tip of the cone formed is connected to the slack sleeve 8, and the joint is sealed with a sealing paste 6. The connecting bolt 11 is located on the cone. The two sides of the cone body are arranged symmetrically along the central axis of the cone body. The opening at the other end of the cone body is provided with a steel plate 2 that matches the port and is fixed by welding. The branching opening 10 of the concave circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com