Conduction oil electric heating box

A technology of electric heating and heat conduction oil, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of oil leakage, high use cost, and low thermal efficiency, so as to reduce the use cost and facilitate maintenance , heat stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further specifically described below in combination with specific embodiments.

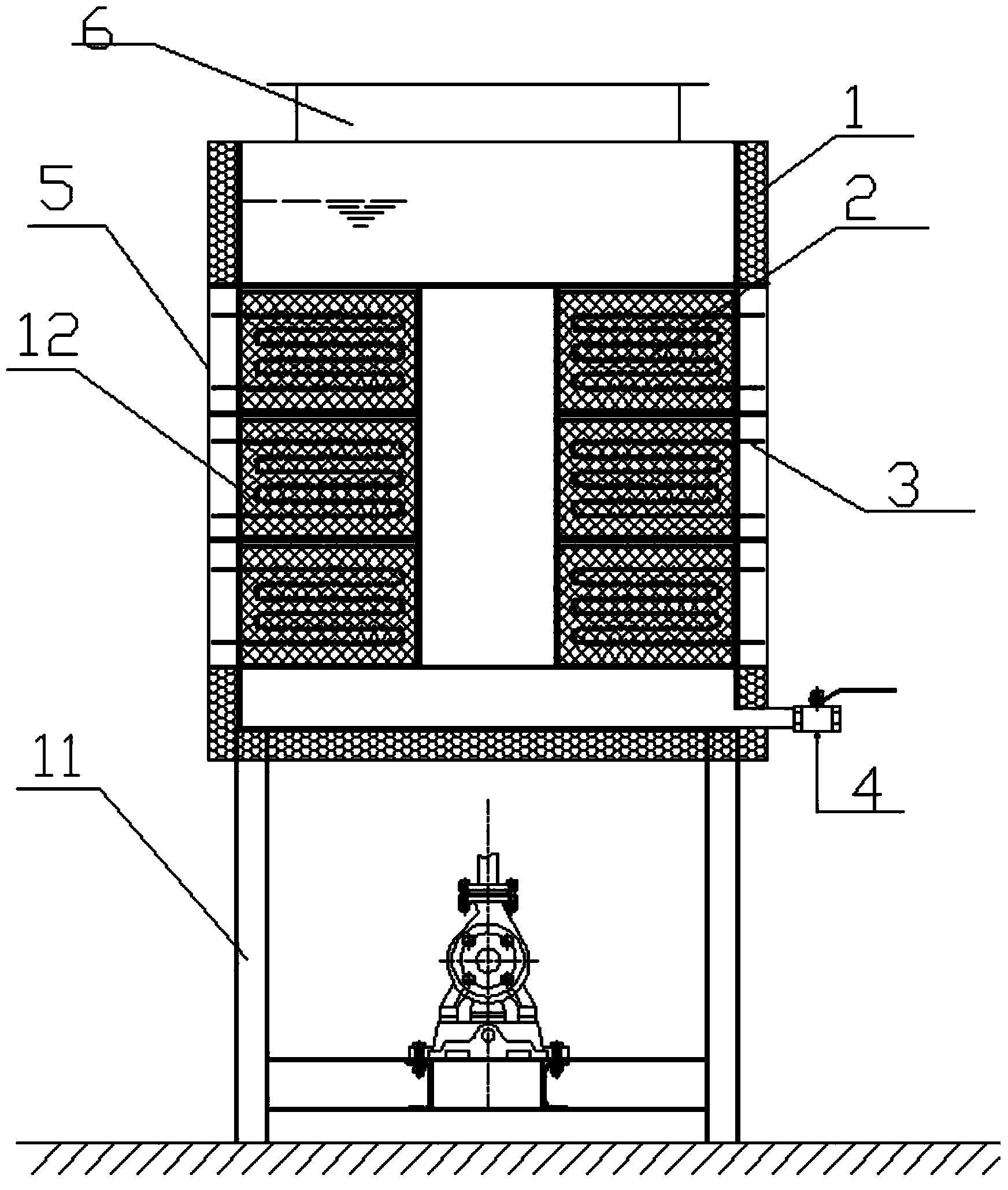

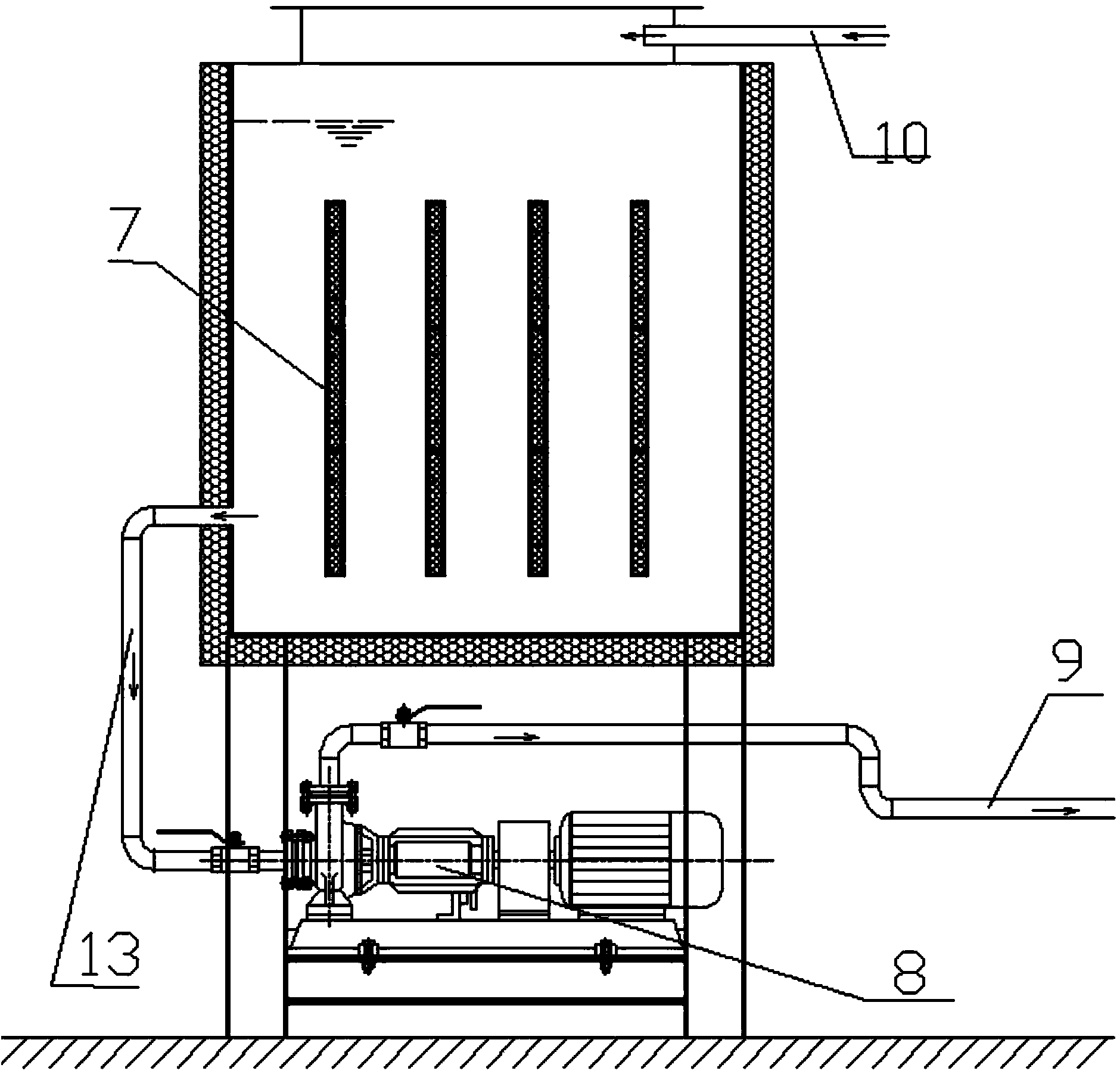

[0017] Such as figure 1 , figure 2 As shown, a heat conduction oil electric heating box includes a box body 5 and a bracket 11, the box body 5 is installed on the bracket 11, the upper end of the box body 5 is provided with a refueling hole 6, and the refueling hole 6 is connected with a circulating oil refueling pipe 10, The circulating oil refueling pipe 10 is connected with the material heating tank, the inner layer of the box body 5 is provided with a rock wool insulation layer 1; the box body 5 is provided with four hot boxes 7, and each hot box 7 is equipped with six sets of hot box grids 12. There are four silicon carbide electric heating plates 2 in the hot box grid 12, and the four electric heating plates in each hot box grid are connected in series to form a group, and every three groups of silicon carbide electric heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com