Liquid small flow standard device with double-piston rack and pinion

A standard device, two-piston technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

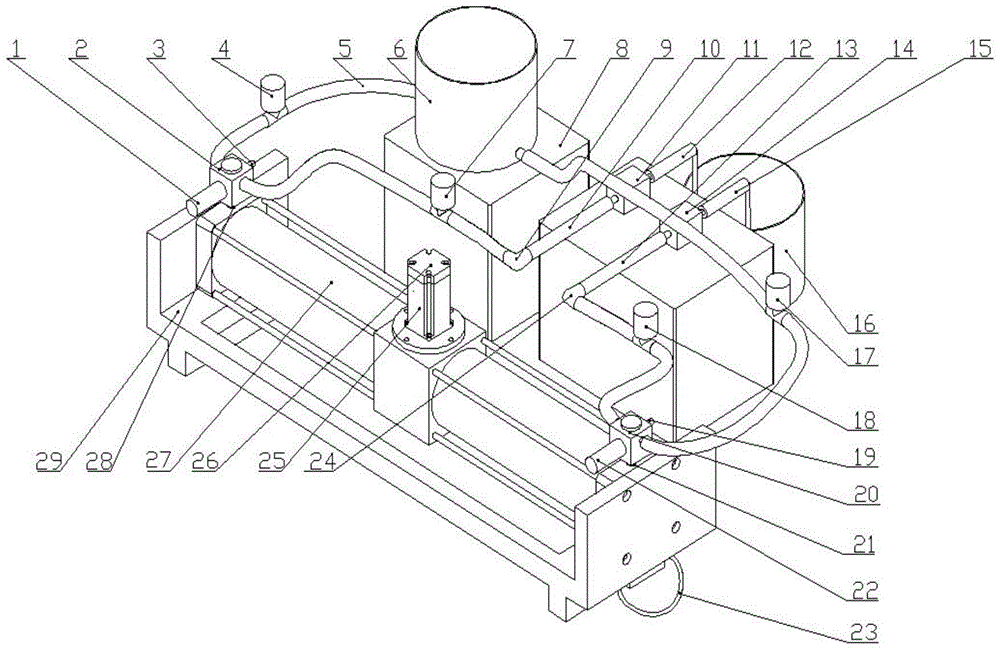

[0015] Such as figure 1 As shown, the double-piston rack-and-gear hydraulic cylinder 27 is fixed on the base 29 by screws, and handles 23 are installed on the left and right sides of the base 29. The servo motor 25 cooperates with the high-precision rack and pinion of the hydraulic cylinder 27 to rotate through keys, and the hydraulic cylinder The left and right water outlets of 27 are all connected to buffer boxes 2, 20 by stainless steel joints 28, 21, and pressure sensors 1, 22 and temperature sensors 3, 19 are respectively installed on both sides of buffer boxes 2, 20; before and after buffer boxes 2, 20 The sides are respectively connected to the solenoid valves 7, 4, 17, 18 through the corrugated hose 5; the water inlets of the solenoid valves 4 and 17 are connected to the water inlet tank 6, and the water inlet tank 6 is placed on the water tank support base 8, and the solenoid valve The water outlets of 7 and 18 are connected with the flowmeters 11 and 14 to be tested ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com