Flame detector with angle convenient to adjust

A flame detector and angle adjustment technology, which is applied in the field of flame detectors, can solve the problems of unfavorable flame detector detection performance and affecting the detection accuracy of flame detectors, and achieve excellent cooling effect, good angle adjustment performance, and ensure the effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

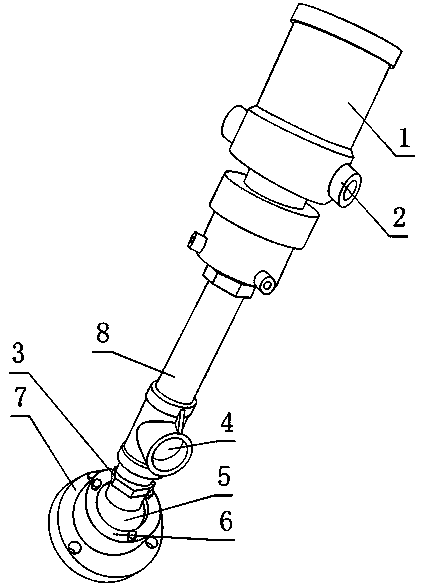

[0021] Such as figure 1 , a flame detector that is convenient for angle adjustment, including a detector body 1, a cooling part and a fixing part, the detector body 1 includes a casing, the casing is in a cylindrical structure, and the two ends of the cooling part are respectively connected to the detector On the opening end and the fixed part of the shell of the body 1;

[0022] The cooling part includes an air duct 8 and an air inlet 4 arranged at any position on the air duct 8;

[0023] The fixed part includes a mounting plate 7, a rolling ball 5 and a ball seat 6, the ball seat 6 is provided with a spherical cavity, the ball seat 6 and the mounting plate 7 are bolted or threaded, and the rolling ball 5 is located on the In the cavity, both ends of the air duct 8 are respectively fixedly connected with the opening end of the housing of the detector body 1 and the rolling ball 5, and the rolling ball 5 is limited between the ball seat 6 and the mounting plate 7;

[0024] T...

Embodiment 2

[0027] The present embodiment is further limited on the basis of embodiment 1, as figure 1 , in order to prevent the formation of cooling wind dead angle on the housing of the detector body 1, the number of the air outlets 2 is multiple.

Embodiment 3

[0029] The present embodiment is further limited on the basis of embodiment 1, as figure 1 , because the flame detector is generally installed inside the equipment or the outside is not easy to be affected by human factors, which makes it inconvenient to adjust the angle of the detector body 1. The angle of the main body 1 is adjusted. The air duct 8 is also provided with a braking part 3 for braking the rotation of the air duct 8. The braking part 3 is provided with at least a pair of parallel planes. The mutually parallel planes are clamping points of the brake part 3 by tools such as a wrench.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com