Shear strain type pressure sensor

A technology of pressure sensor and strain type, which is applied in the field of shear strain type pressure sensor, can solve the problems of low resolution, insensitivity to small strain, and the range of force measurement needs to be improved. The effect of good reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

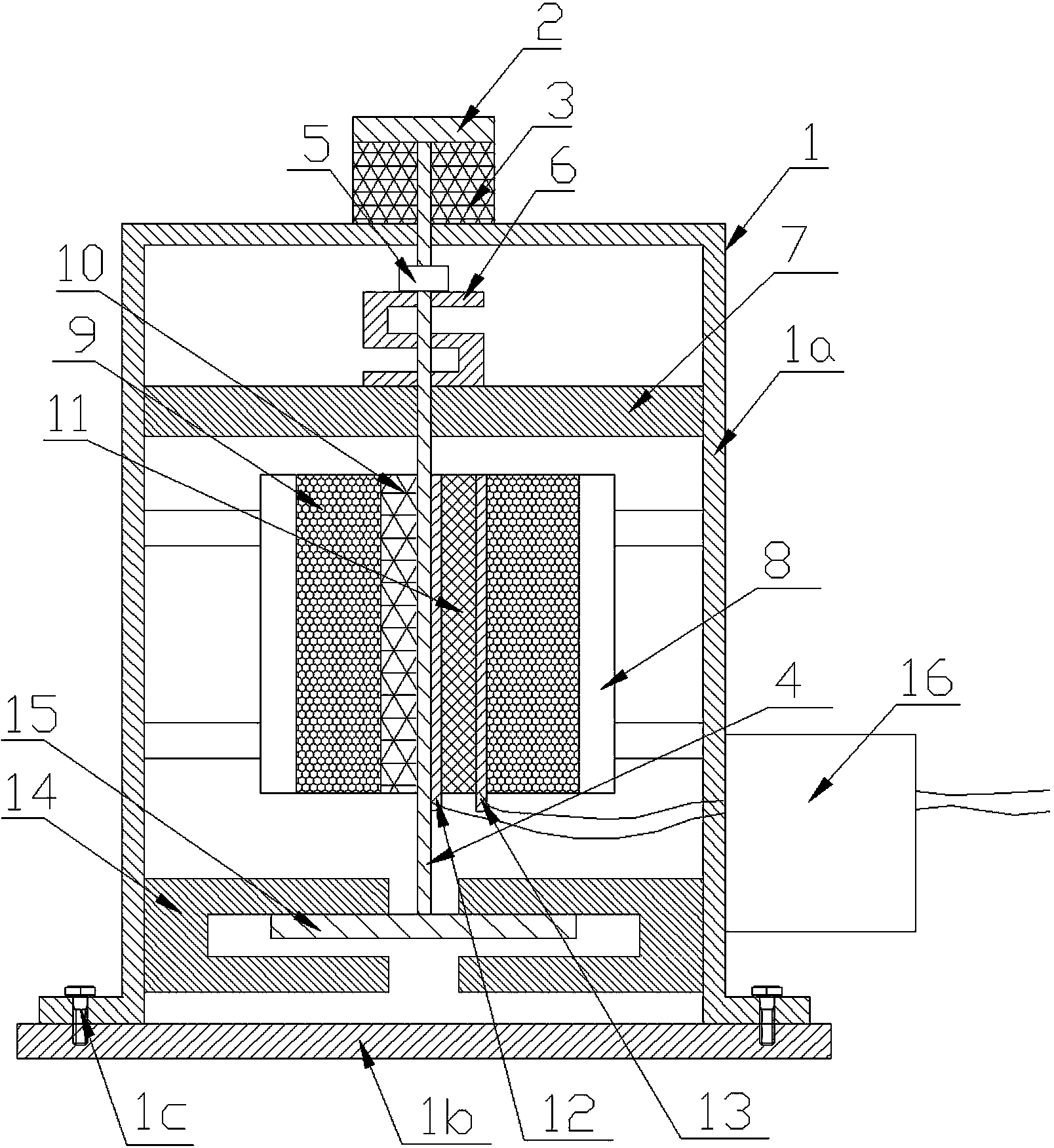

[0020] See figure 1 , A shear strain pressure sensor, including a housing 1. A magnetic field generating device is fixed in the housing 1, and the magnetic field generating device has two opposite magnetic poles and corresponding opposite magnetic poles, a space is left between the two magnetic poles, and the space between the two magnetic poles is set There is a shearing plate 4, one side of the shearing plate 4 is fixed with a rubber sheet 10, which is in full contact with the pole end face of the first pole of the two poles. The matrix of the magnetorheological elastomer 11 is rubber. When it is subjected to shearing, there will be deformation in the vertical direction. The rubber sheet 10 is added for the symmetry of the two sides of the shear plate 4 and the compatibility with the magnetorheological elastomer 11. Coordinate movement. A first electrode 12 is fixed on the other side of the shear plate 4, a magnetorheological elastic body 11 is fixed on the first electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com