Dynamic conductivity testing device for oil-water mixture and usage thereof

A technology of oil-water mixing and testing equipment, applied in the direction of fluid resistance measurement, etc., can solve the problems of inconsistent test conditions and actual working conditions, poor reproducibility of measurement results, etc., achieve stable test conditions, realize dynamic measurement, and avoid static stratification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

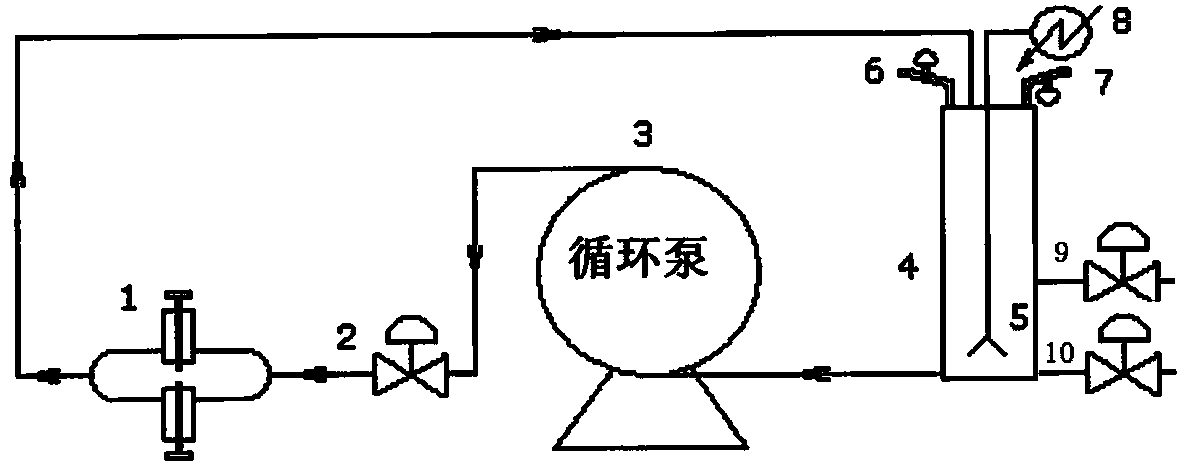

[0023] A device for testing the conductivity of a dynamic oil-water mixture, comprising a test section 1, a fluid controller 2, a circulation pump, a test liquid storage tank 4 and a test liquid circulation pump 3; one end of the test section 1 is connected to the fluid controller 2 , the other end is connected with the test liquid storage tank 4; the fluid controller 2 is connected with the test liquid storage tank 4 through the test liquid circulation pump 3; the top of the test liquid storage tank 4 is provided with a gas inlet 6 and a gas outlet 7; The bottom of the test liquid storage tank 4 is provided with a test liquid discharge port 9 and a test waste liquid discharge port 10; the inside of the test liquid storage tank 4 is provided with a stirrer 5 .

Embodiment 2

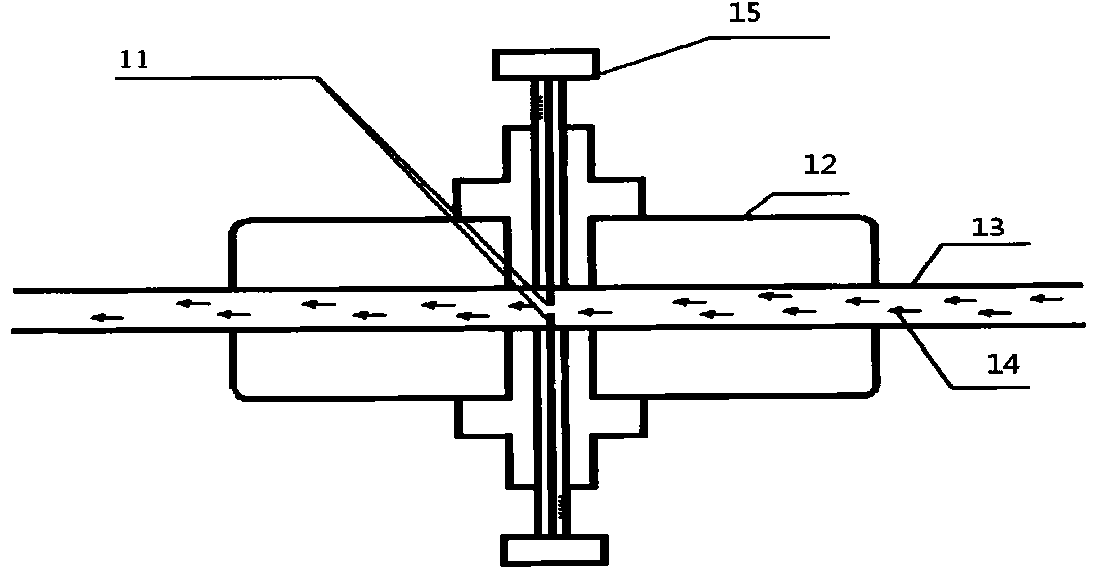

[0025] A device for testing the conductivity of a dynamic oil-water mixture, which is similar to Example 1, except that the test section 1 adopts a horizontal pipeline 13, which includes two vertically oppositely placed measuring electrodes 11, and the two measuring electrodes 11 and It is connected with the adjustment nut and the adjustment screw 15, and the distance between the two measuring electrodes 11 can be adjusted through the adjustment screw.

Embodiment 3

[0027] A testing device for the conductivity of a dynamic oil-water mixture is similar to Embodiment 2, the difference is that a test section support mechanism 12 is provided outside the horizontal pipeline 13, and the test section 1 can be adjusted to keep it horizontal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com