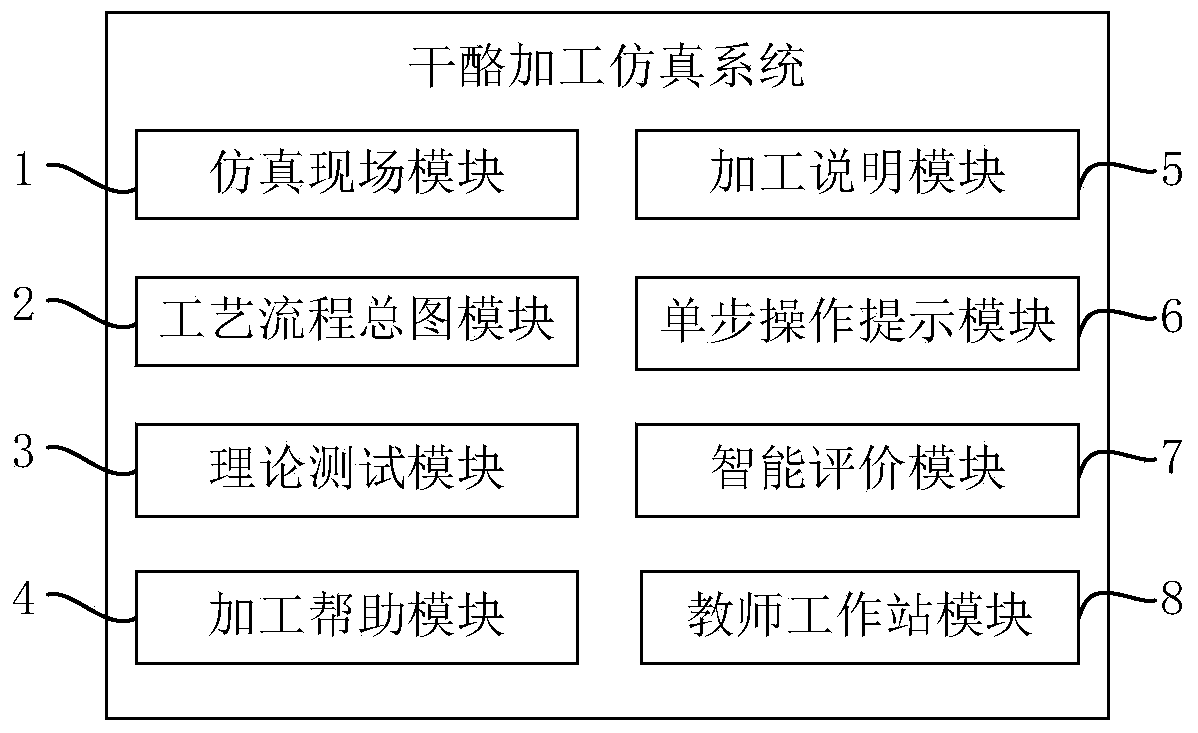

Cheese-processing simulation system

A technology of simulation system and cheese processing, which is applied in the field of simulation system, can solve the problems of not being able to clearly understand the internal structure, and achieve the effect of self-learning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

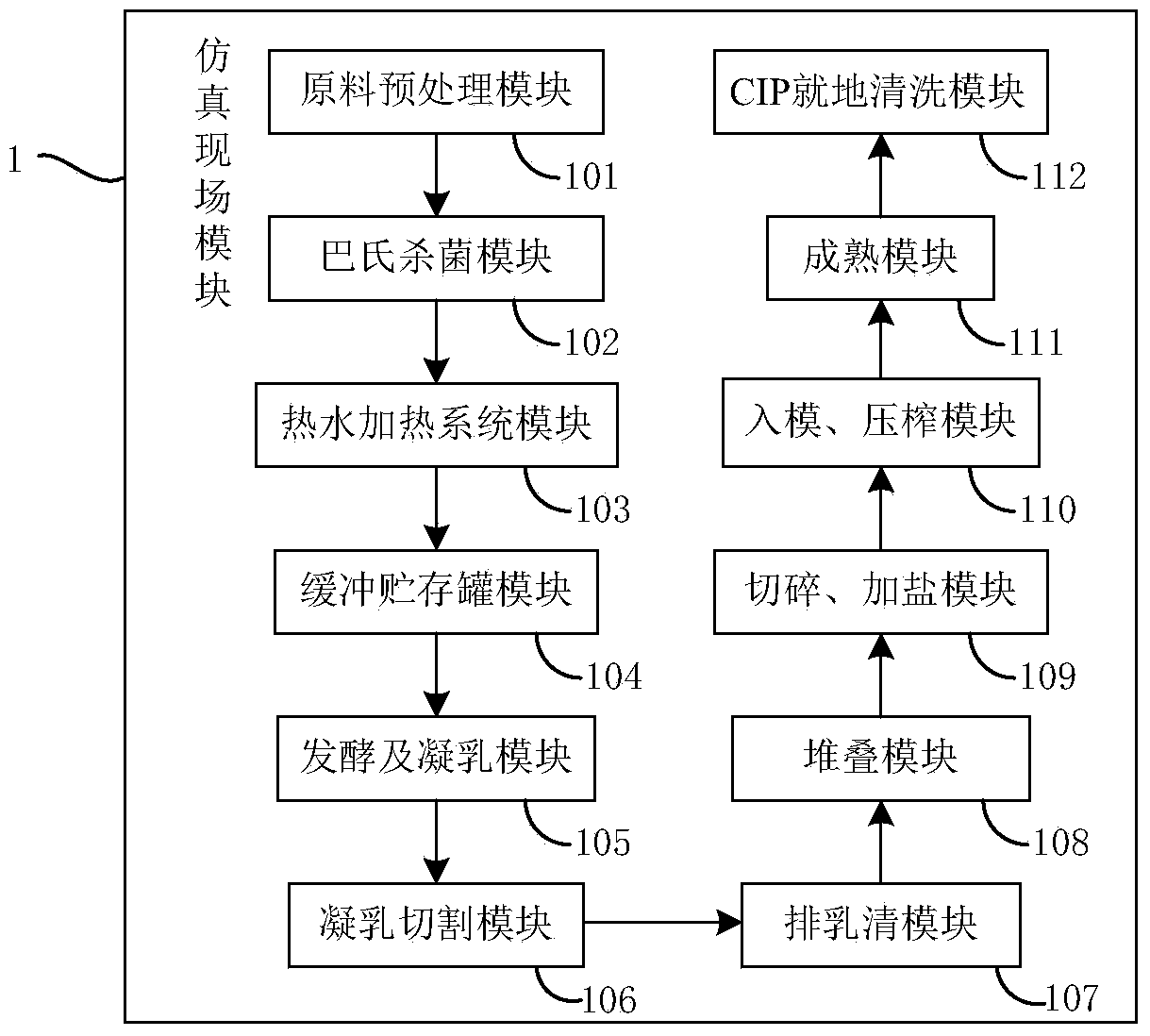

[0036] Example: Cheddar Cheese Simulation System Operation:

[0037] The first step is to open the simulation field module 1, and in the pop-up raw material pretreatment module 101, click on the double cylinder filter valve, open the inlet of the jacket water of the raw milk storage tank, the outlet valve of the vacuum pump in turn, start the vacuum pump, and open the inlet of the vacuum pump Switch, adjust the pressure of the degassing tank, open the milk tanker, turn on the milk delivery pump, adjust the temperature of the raw milk storage tank, and turn off the vacuum pump after the milk in the degassing tank is pretreated to the raw material storage tank.

[0038] The second step is to run the hot water heating system module 103, click on the hot water heating inlet circulation system, fill the pipeline with hot water, open the hot water pump outlet switch valve, start the hot water pump, open the hot water pump inlet switch valve, and the hot water system pipeline After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com