Low Alloy Steel

A low-alloy steel, post-welding heat treatment technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problem of insufficient performance, and achieve the effect of excellent hydrogen embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

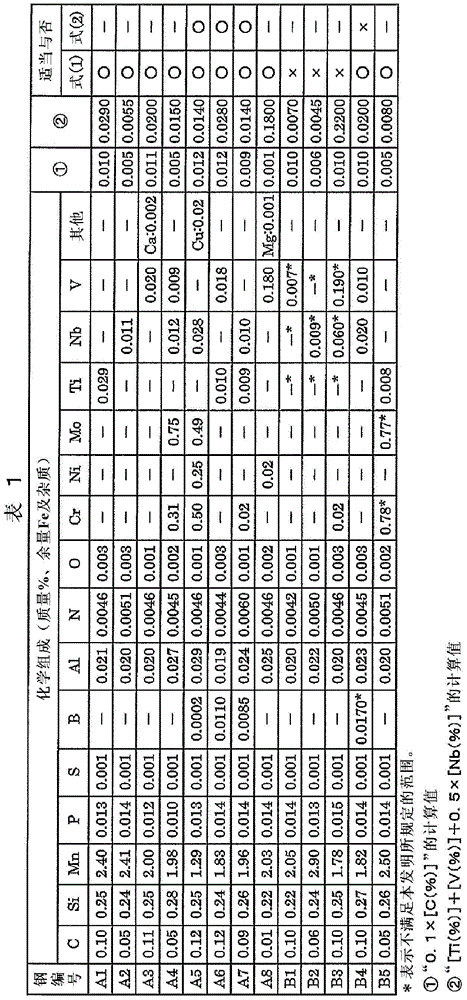

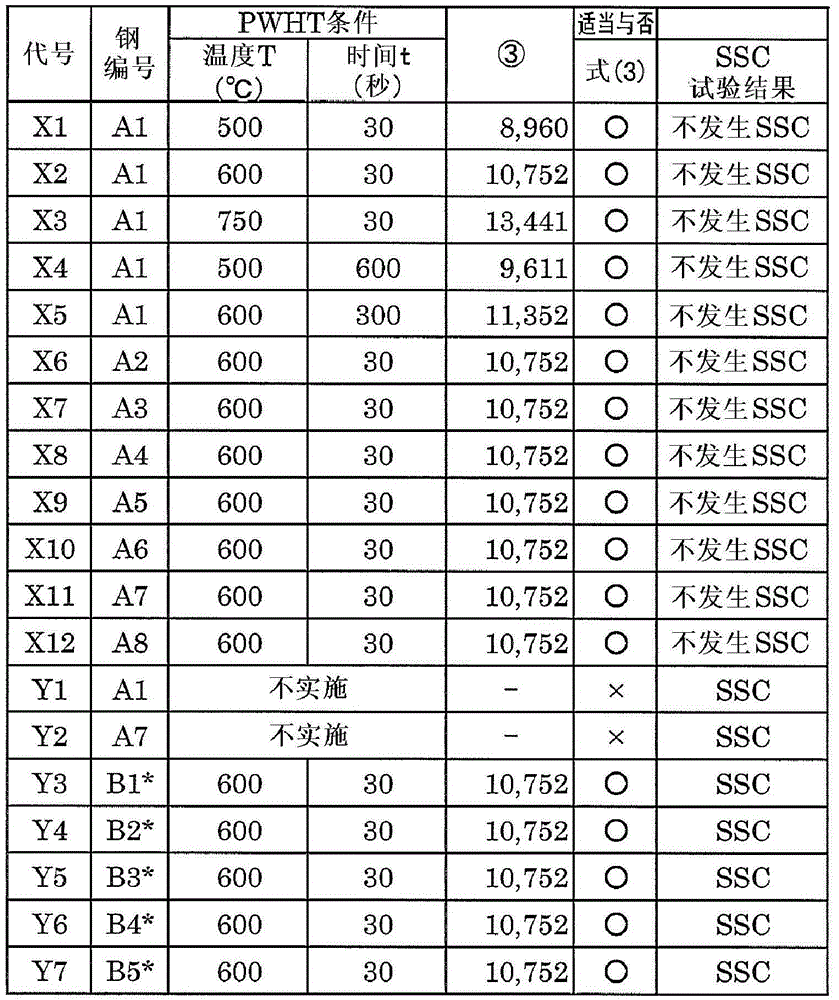

[0084] In order to confirm the effects of the present invention, the following experiments were conducted. That is, a low-alloy steel plate with a thickness of 12 mm having the chemical composition shown in Table 1 was machined into a 12 mm square and 100 mm long to produce a test material. The test material was subjected to a HAZ simulated welding thermal cycle, that is, heating by high-frequency induction heating to a temperature of 1350° C. at which the HAZ hardens significantly, followed by rapid cooling for 3 seconds. The following test was performed using this test material.

[0085]

[0086] According to JIS Z2241, a round bar tensile test piece having a parallel portion diameter of 6 mm and a parallel portion length of 10 mm was collected from the obtained test material, and a tensile test at normal temperature was performed.

[0087]

[0088] A test piece having a thickness of 2 mm, a width of 10 mm, and a length of 75 mm was collected from the obtained test mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com