A steam boiler comprising a radiation element

A technology of radiant elements and steam boilers, applied in the direction of steam superheating, boiler water pipes, steam generation, etc., which can solve the problems of large complexity and cost, and increased wear of superheater tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

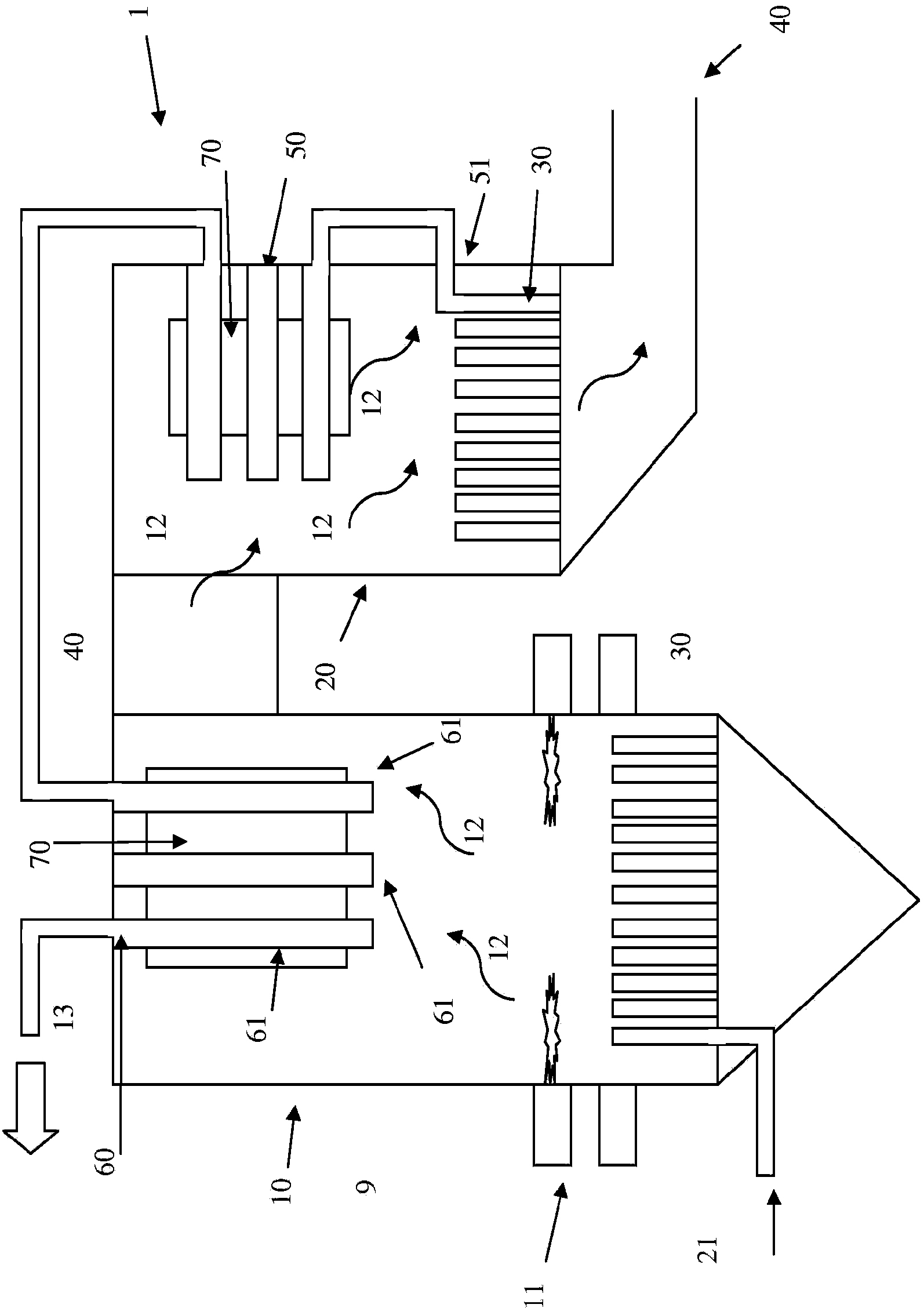

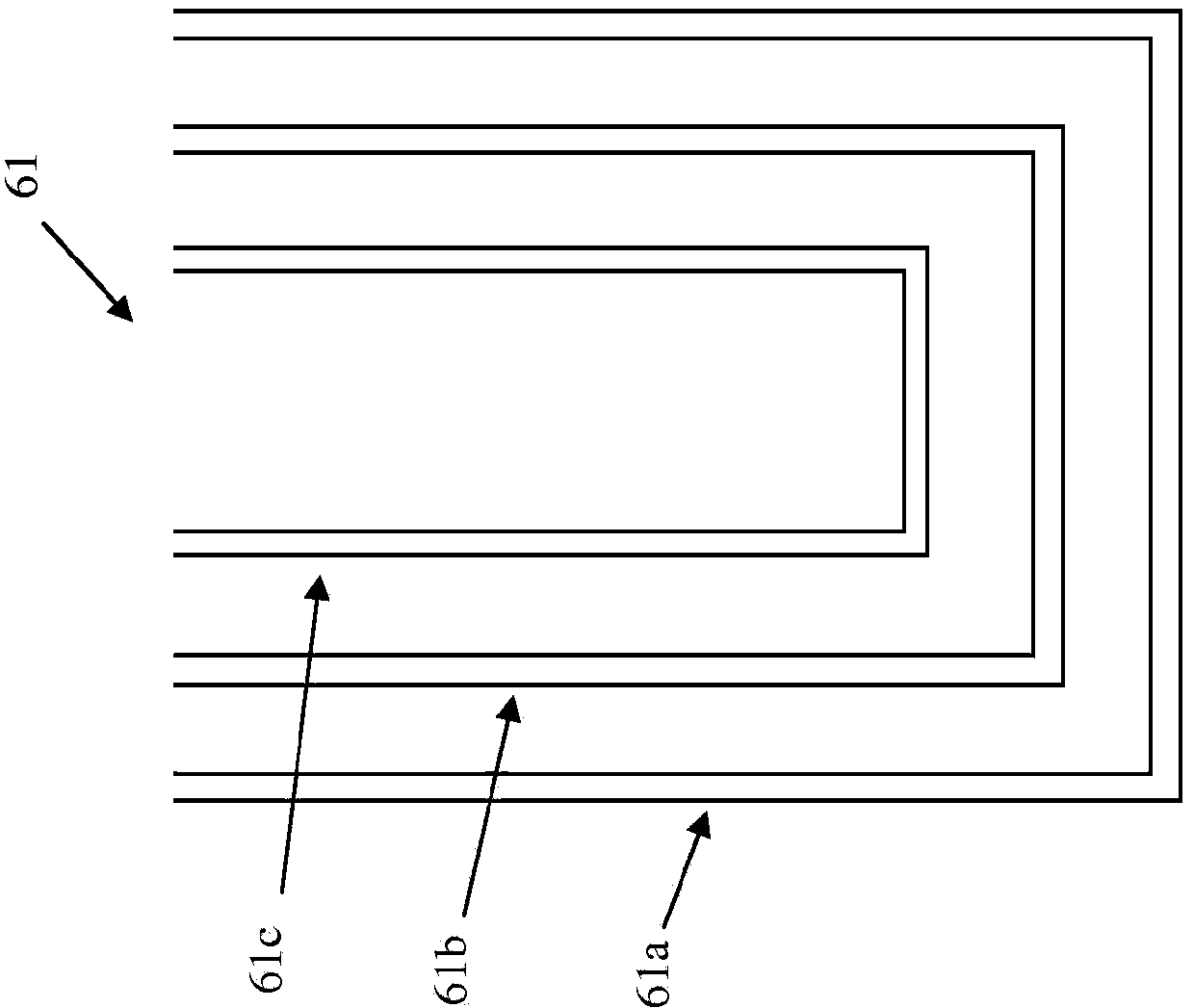

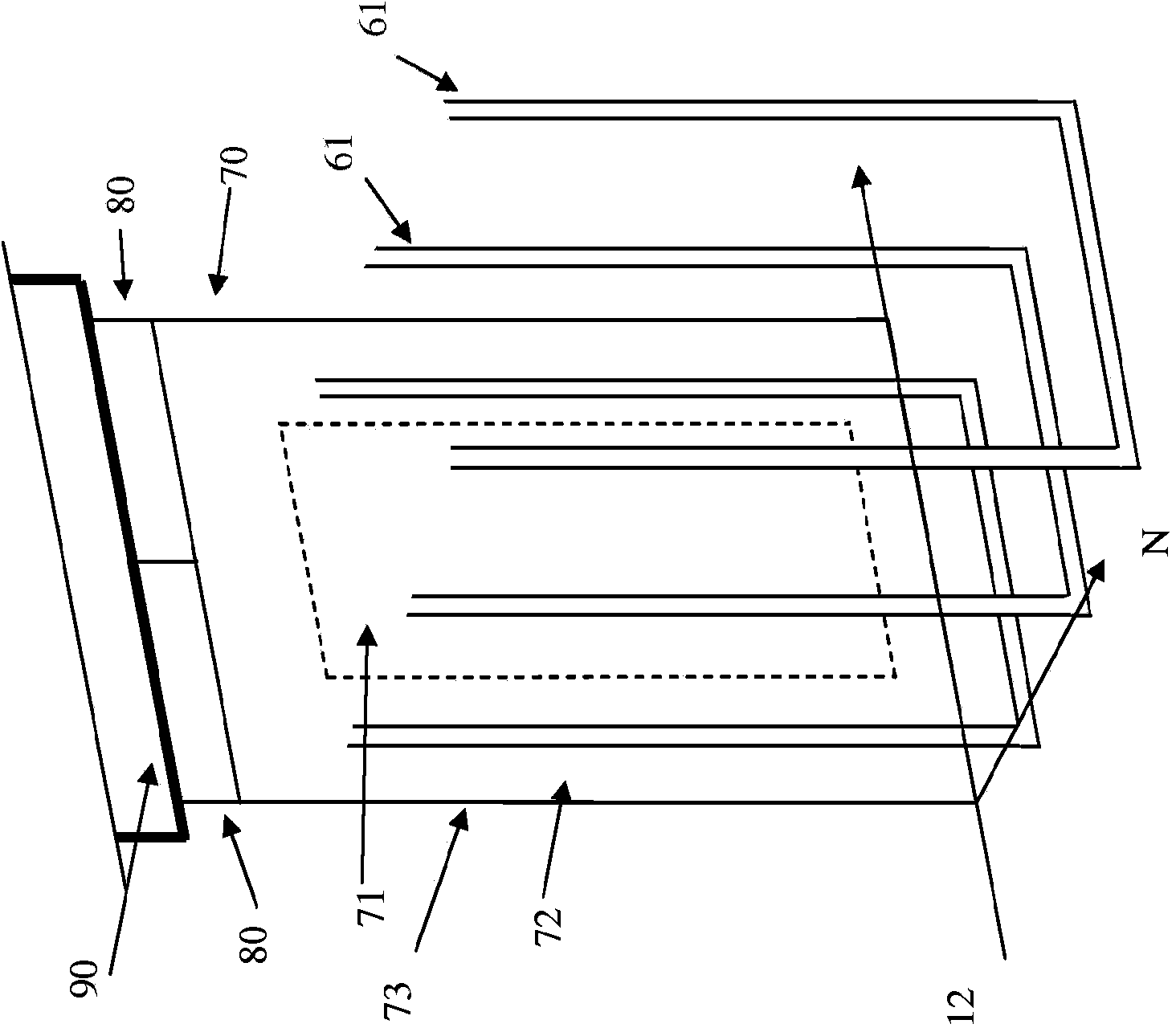

[0107] In the following, the heating effect of the radiation element of the present invention in a steam boiler will be shown through a calculation example. In the examples, temperature and heat transfer calculations have been made based on empirical data from conventional boiler designs. The smoke absorption and emission coefficients are assumed to be equal, and all surfaces are assumed to have emission and absorption coefficients of 0.8 and also have the same convective heat transfer. For the calculation, primary radiation, primary and secondary reflections and absorption in the gas volume have been considered.

[0108] Calculations showing the heat absorbed in the superheater arrangement in an oil fired compact boiler. Calculations were performed for the inventive superheater arrangement with radiating elements and for a conventional superheater arrangement without radiating elements.

[0109] Figure 6 A side view showing a conventional superheater tube arrangement. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com