Laboratory sample distribution system and corresponding method of operation

A distribution system and laboratory technology, applied in the direction of analysis materials, instruments, conveyors, etc., can solve the problem that it is difficult to realize the independent and synchronous movement of multiple specimen transport racks, and achieve the effect of improving self-support and smooth transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

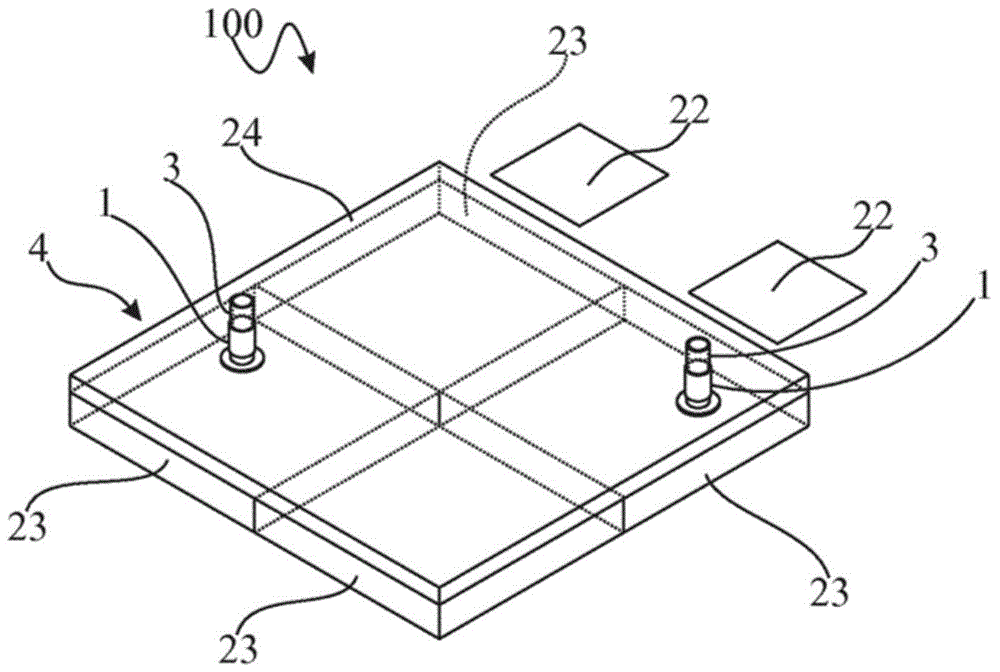

[0064] figure 1 A laboratory sample distribution system 100 is shown. The laboratory sample distribution system 100 is used to distribute samples or specimens, such as contained in sample containers or Blood sample in sample tube 3.

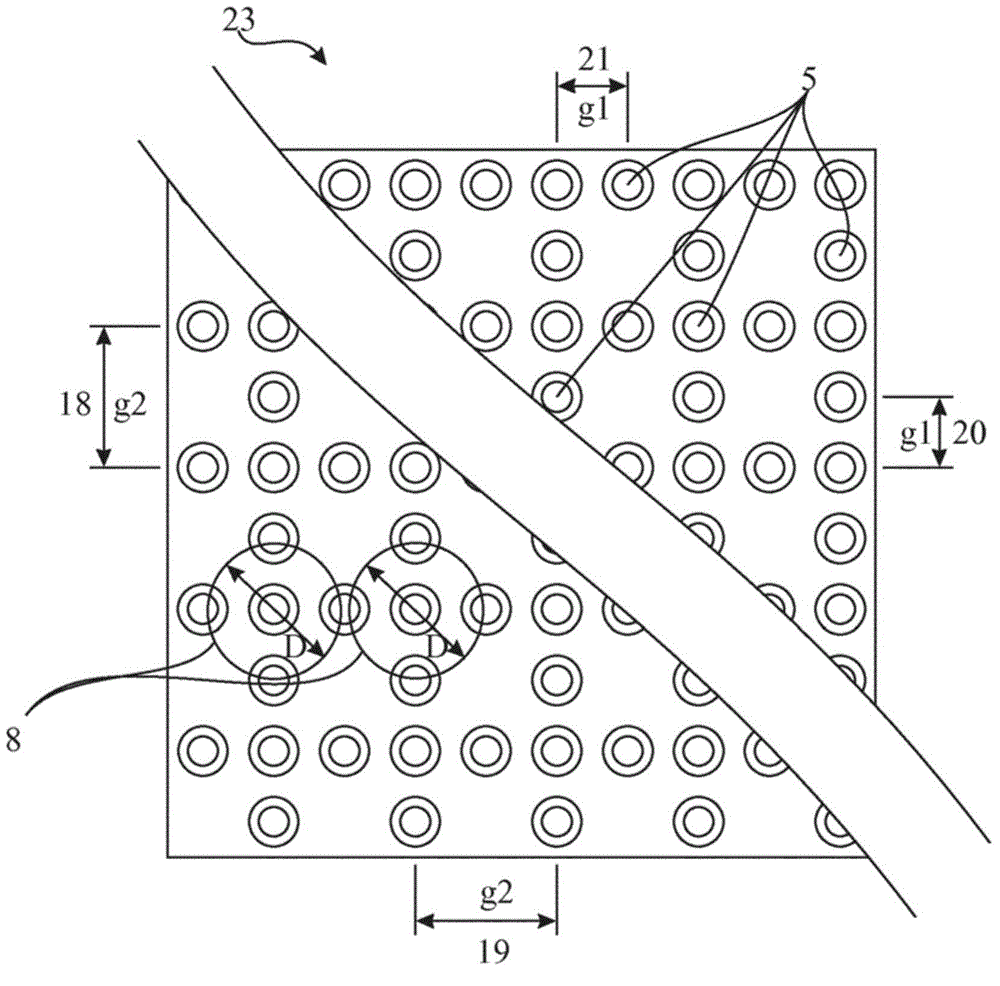

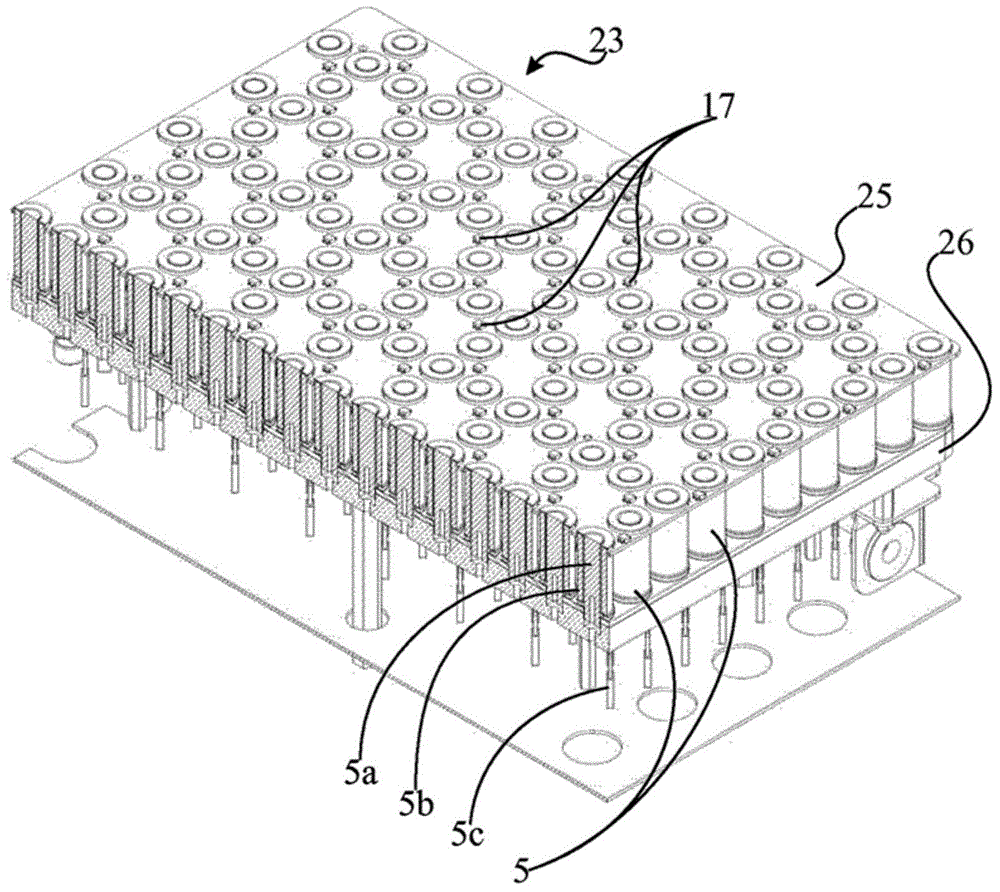

[0065] The laboratory sample distribution system 100 comprises a plurality of container carriers or single tube carriers 1 each adapted to carry a respective sample container 3 on a transport plane 4 . A plurality of electromagnetic actuators 5 (see figure 2 and 3 ) is fixedly arranged below the transport plane 4 . Each electromagnetic actuator 5 is adapted to move the container carrier 1 within the operating distance of the corresponding electromagnetic actuator 5 by applying a magnetic force to the container carrier 1 .

[0066] The transport plane 4 shown is divided into four secondary sub-planes 23 which are arranged adjacent to each other. The transport plane is covered by an optional cover profile 24 which is fluid-tight and covers g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com