Rolling process shared by round hole with diameter of 5.5 and threaded hole with diameter of 6.0

A thread and process technology, applied in the field of metal wire rod rolling, can solve the problems of long time delay in changing rolls and grooves, waste of time in changing rolls and grooves, and high labor intensity, so as to shorten the time for changing rolls and grooves and ensure normal operation. , The effect of equipment stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

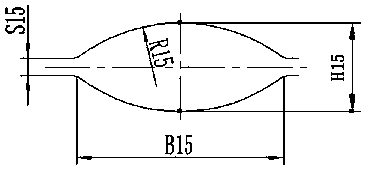

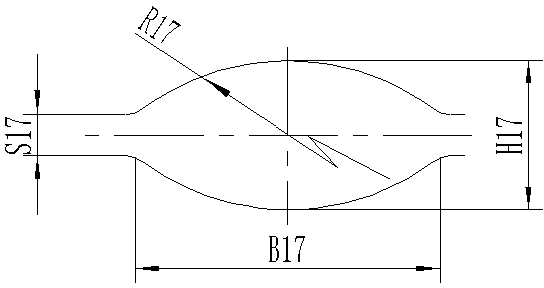

[0038] Example 1 rolling circle 5.5mm

[0039] There are 28 rolling mills in total, which are rough rolling unit, intermediate rolling unit, pre-finishing rolling unit and finishing rolling unit. Among them, the 1#-6# rolling mill is the rough rolling group, the 6#-12# rolling mill is the intermediate rolling group, the 13#-14# rolling mill is the pre-finishing rolling group one, and the 15#-18# rolling mill is the pre-finishing rolling group Unit 2, No. 19#-28# rolling mills are finish rolling units, of which the rough rolling unit, intermediate rolling unit and pre-finishing rolling unit 1 are horizontal and vertical alternately, and the pre-finishing rolling The rolling unit is Hafei imitating Morgan 45°, and there is no requirement for the pass type of 1#-14# in the front, as long as the material shape area S of 14# is guaranteed to meet 530mm 2 , 15#-27# rolling mills set the roll ring passes of each shift according to the following pass parameters,

[0040] 15# rolli...

Embodiment 2

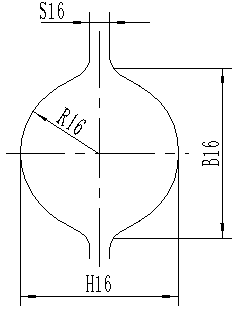

[0055] Example 2 rolling screw 6.0mm

[0056] There are 28 rolling mills in total, which are rough rolling unit, intermediate rolling unit, pre-finishing rolling unit and finishing rolling unit. Among them, the 1#-6# rolling mill is the rough rolling group, the 6#-12# rolling mill is the intermediate rolling group, the 13#-14# rolling mill is the pre-finishing rolling group one, and the 15#-18# rolling mill is the pre-finishing rolling group Unit 2. The 19#-28# rolling mills are finish rolling units, of which the rough rolling unit, intermediate rolling unit and pre-finishing unit 1 are horizontal and vertical alternately, and the pre-finishing rolling The rolling unit is Hafei imitating Morgan 45°, and there is no requirement for the pass type of 1#-14# in the front, as long as the material shape area S of 14# is guaranteed to meet 530mm 2 , 15#-27# rolling mills set the roll ring passes of each shift according to the following pass parameters,

[0057] 15# rolling mill i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com