A hydraulic buffer hinge

A hydraulic buffer and hydraulic buffer technology, which is applied in the field of door hinges, can solve the problems of large space occupation, complicated installation, and short service life of door closers, and achieve the effects of eliminating tangential force, closing smoothly, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

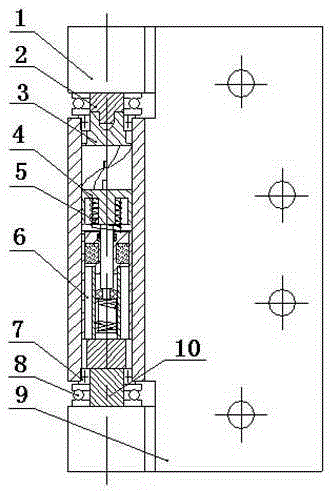

[0028] Combine below Figure 1 to Figure 6 , the present invention is further described:

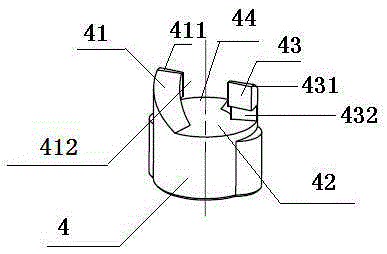

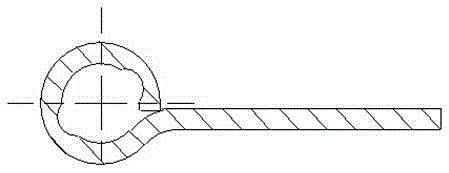

[0029] as attached figure 1 As shown, the hydraulic buffer hinge is composed of a double-ear leaf 1, a transmission shaft 2, a rotating cam 3, a compression cam 4, a return spring 5, a hydraulic buffer 6, a miniature flanged bearing 7, a miniature plane thrust ball bearing 8, Single ear sheet 9 and plug 10 are formed. A plug 10, a hydraulic buffer 6, a compression cam 4, a rotating cam 3, and a drive shaft 2 are sequentially arranged inside the common connecting shaft of the double-ear leaf 1 and the single-ear leaf 9; the boss of the drive shaft 2 is inserted into the In the groove at the bottom of the rotating cam 3, a miniature planar thrust ball bearing 8 is provided on the periphery of the boss of the transmission shaft 2, and a miniature bearing with a flange 7 is arranged on the periphery of the bottom of the rotating cam 3; The top is also provided with miniature flat thrust b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com