Subway gearbox box

A technology for gear boxes and boxes, which is applied in the directions of gear lubrication/cooling, belts/chains/gears, and transmission boxes. Temperature rise, effective and reliable lubrication, and the effect of improving the sealing performance of the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

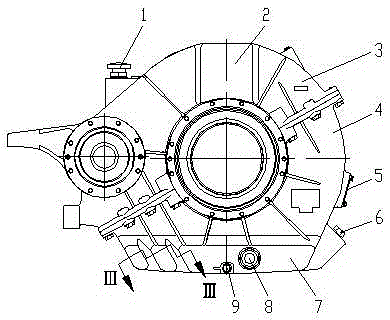

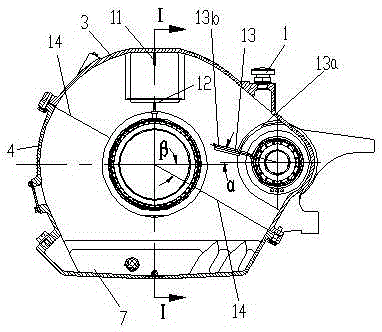

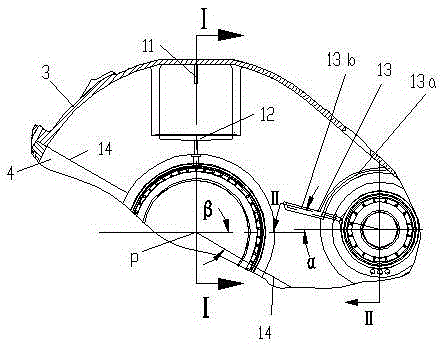

[0023] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, the subway gearbox casing of the present invention includes an upper casing 3 and a lower casing 4, and the lower casing 4 is provided with an observation window 5, an oil mark 8, Oil injection screw plug 6 and oil discharge screw plug 9, the bottom of lower box body 4 is provided with oil pool 7, and described upper box body 3 and lower box body 4 are provided with large bearing seat support hole 15, and described upper box body 3 There is also a small bearing seat support hole 20 on the top, and the inner wall of the upper box body 3 is provided with a large bearing oil sump 12 and a small bearing oil sump 13, and the large bearing oil sump 12 is composed of the first box wall section 12-3 and The first oil groove baffle plate 12-1 is formed and is located on the top of the large bearing seat support hole 15. The bottom of the large bearing oil sump 12 communicates with the large bearing seat support hole 15 through the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com