Ceramic mud flow velocity detection device and detection method

A technology of current detection device and flow velocity detection, which is applied in measurement devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of affecting continuous production, unable to detect in real time, reducing production efficiency, etc., so as to avoid detection results. Inaccurate, save testing time, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

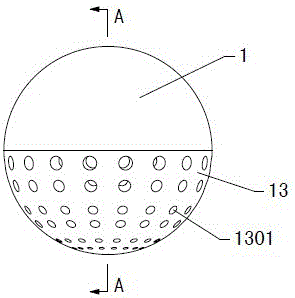

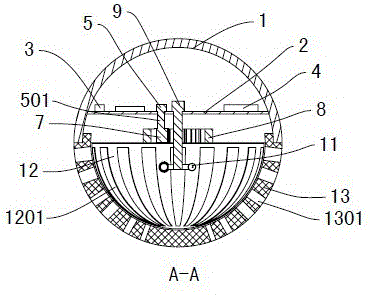

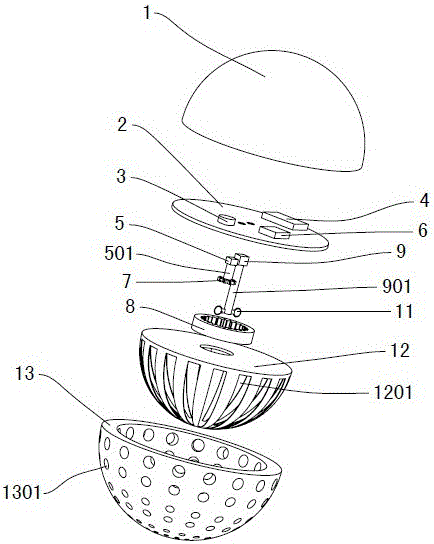

[0034] Figure 1~5 It is the best embodiment of the ceramic mud flow velocity detection device and detection method of the present invention, below in conjunction with the attached Figure 1~8 The present invention will be further described.

[0035] refer to Figure 1~3, the ceramic mud flow velocity detection device includes an upper casing 1, a lower casing 13, a flow velocity detection motor 9, a current detection device and a mud stirring mechanism, and the flow velocity detection motor 9 is fixed on the upper casing 1 and the lower casing 13 which are sealed and connected On the inner side, the lower casing 13 is provided with a plurality of mud passing holes 1301, and the mud stirring mechanism is fixed on the lower end of the detection output shaft 901 of the flow velocity detection motor 9, and the flow velocity detection motor 9 drives the stirring mechanism to stir the ceramic slurry in the lower casing 13, and the current The detection device detects the current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com