Head with Extended Collar

A drum head and collar technology, applied in musical instruments, percussion instruments, instruments, etc., can solve problems such as reducing output and achieve the effect of improving tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

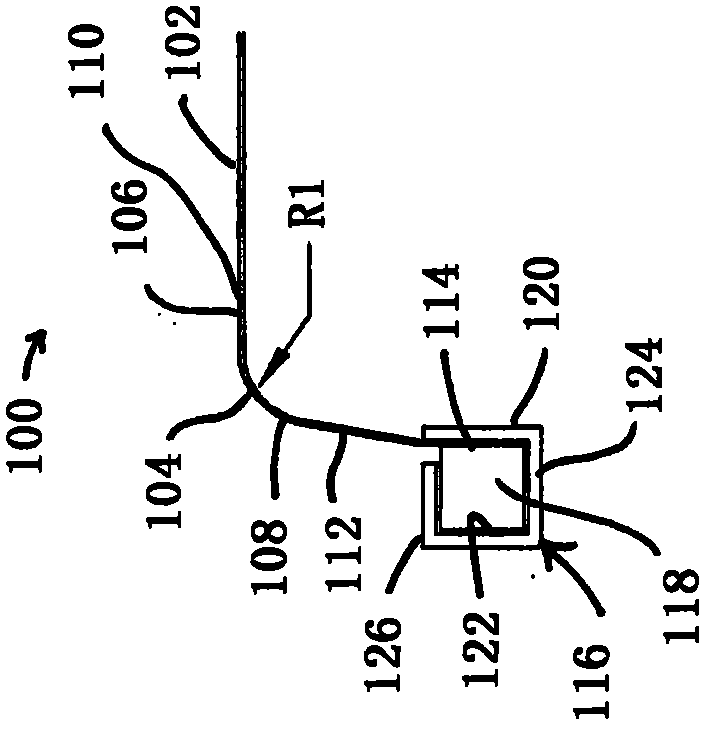

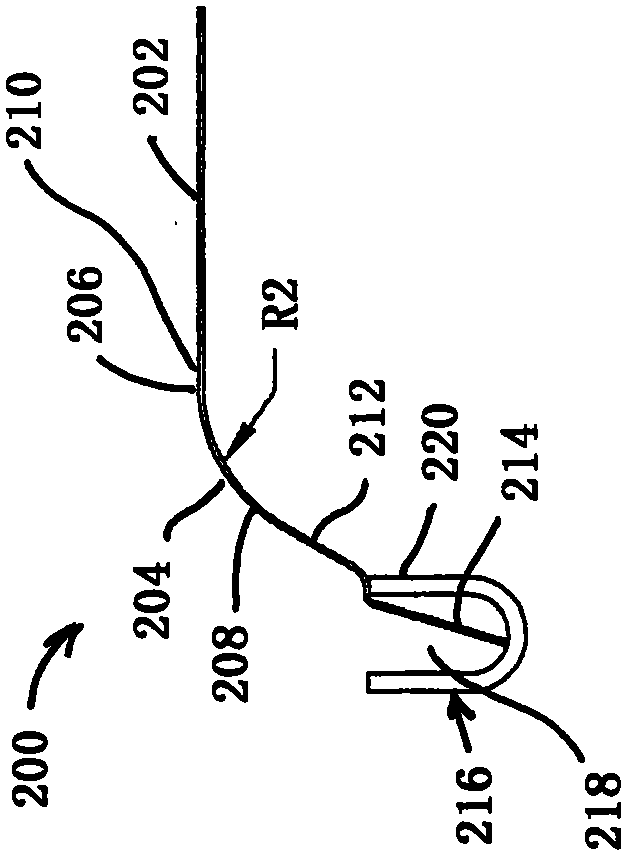

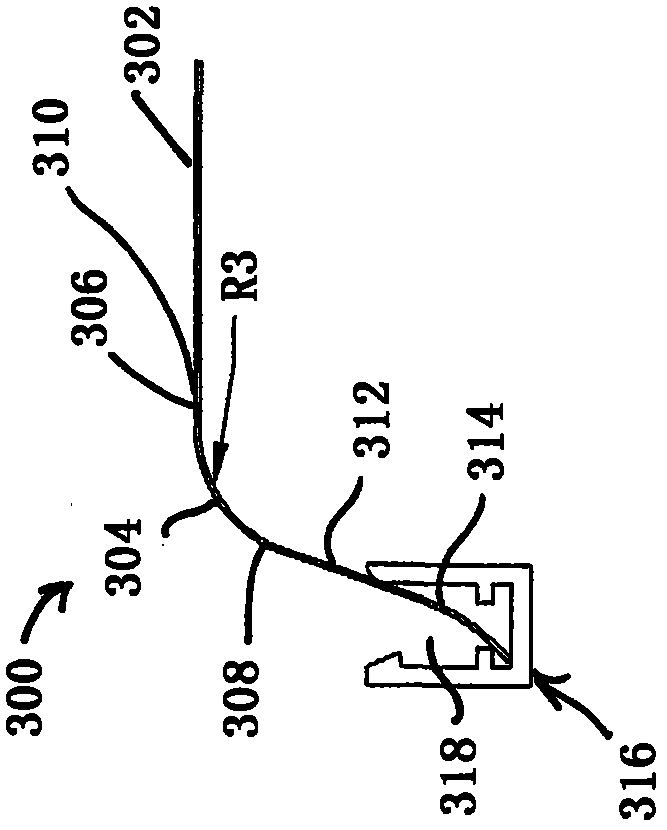

[0019] Figure 1-4 Shows a cross-section of one side of a prior art drumhead having a differently shaped curved collar extending generally outward and downward from the central play area to the hoop. It should be understood that drums have different sizes, generally dictated by the nominal diameter of the drum shell, and likewise, drum heads have various corresponding dimensions dictated by the diameter of the drum shell. For convenience, the present disclosure will only focus on a 14 inch nominal diameter head, but it should be understood that similar principles may apply to drums having other diameters.

[0020] exist figure 1 In the embodiment of the present invention, the head 100 has a flat striking area 102 with a diameter of 13.69 inches. Collar 104 has a convex curved region having an upper end 106 and a lower end 108 having a radius R1 of approximately 0.156 inches, wherein the upper end has a tangential transition to the flat strike region 110; and a skirt region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com