Storage rack

A storage rack and vertical plate technology, applied in the field of storage racks, can solve the problems of production impact, material stacking does not meet the requirements, reduce production efficiency, etc., and achieve the effects of convenient assembly, reasonable structure, and strong storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

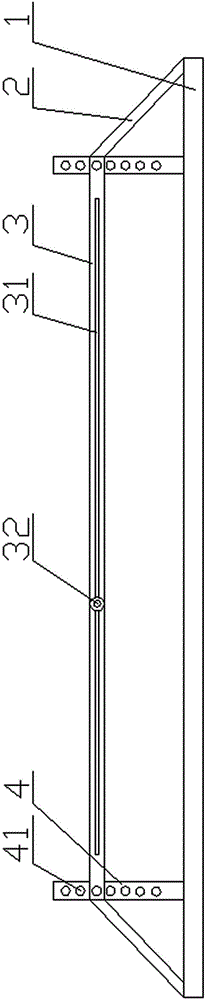

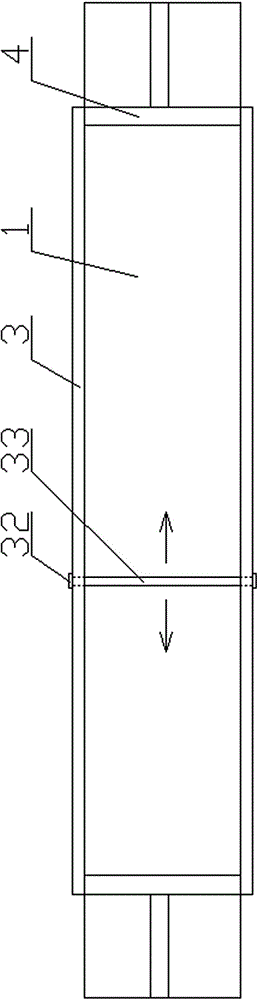

[0015] Such as Figure 1 to Figure 2 Shown, a kind of shelf, comprises bottom plate 1, support rod 2, beam 3, positioning bar 33 and vertical plate 4, and vertical plate 4 is two pieces, and is arranged symmetrically, and the bottom of each vertical plate 4 is connected with bottom plate 1 by hinge. Flexible connection, the side of each vertical plate 4 is provided with support positioning openings, and the front is evenly provided with a plurality of positioning holes 41, there are two support rods 2, and one end of each support rod 2 is movably connected with one end of the bottom plate 1 through a hinge , the other end of which is buckled and fixed with the supporting positioning opening on the vertical plate 4, and there are two crossbeams 3, and the two ends of each crossbeam 3 are respectively fixed on the vertical plate 4 through positioning holes 41 and bolts, and each crossbeam 3 is opened There is a chute 31, and the two ends of the positioning rod 33 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com