Spring energy-storage brake cylinder restorer

A brake cylinder and spring energy storage technology, which is applied in the manufacture of tools, metal processing, metal processing equipment, etc., can solve the problems of increased cost and difficulty in production and use, and achieve high reliability, flexible and light operation, and avoid ejection injuries. human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

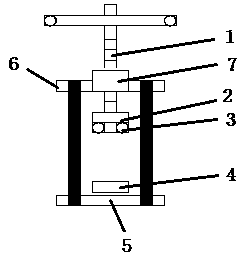

[0012] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a spring energy storage brake wheel cylinder repairer, which comprises a bracket, a force applying part installed on the bracket and a positioning and clamping part. Wherein the force-applying parts include a force-applying lead screw 1 , and a lead screw nut 7 fixed on a support used in conjunction with the force-apply lead screw 1 , and the lead screw nut 7 is fixed on the upper support plate 6 . The hollow sleeve 2 is welded at the lower end of the force screw 1, the lower end of the hollow sleeve 2 is equipped with a thrust bearing 3, and the spring energy storage brake cylinder to be repaired is contained between the thrust bearing 3 and the positioning and clamping parts. The diameter of the inner hole of the thrust bearing 3 and the diameter of the hollow sleeve 2 are slightly larger than the diameter of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com