Fabric cutting machine

A cloth cutting machine and cloth drum technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of low work efficiency and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

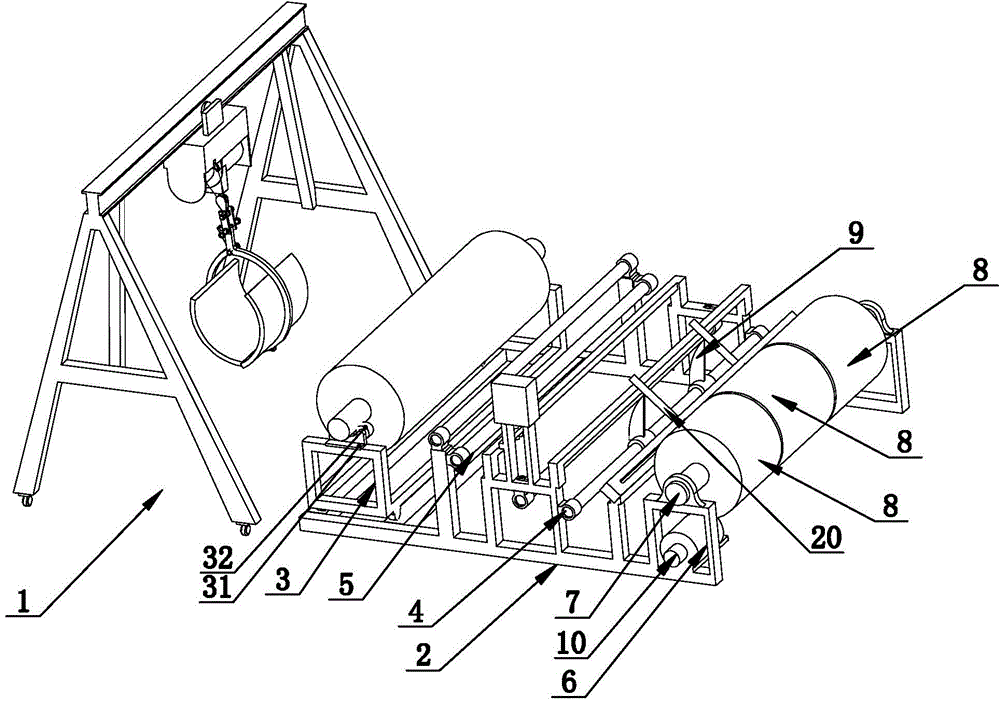

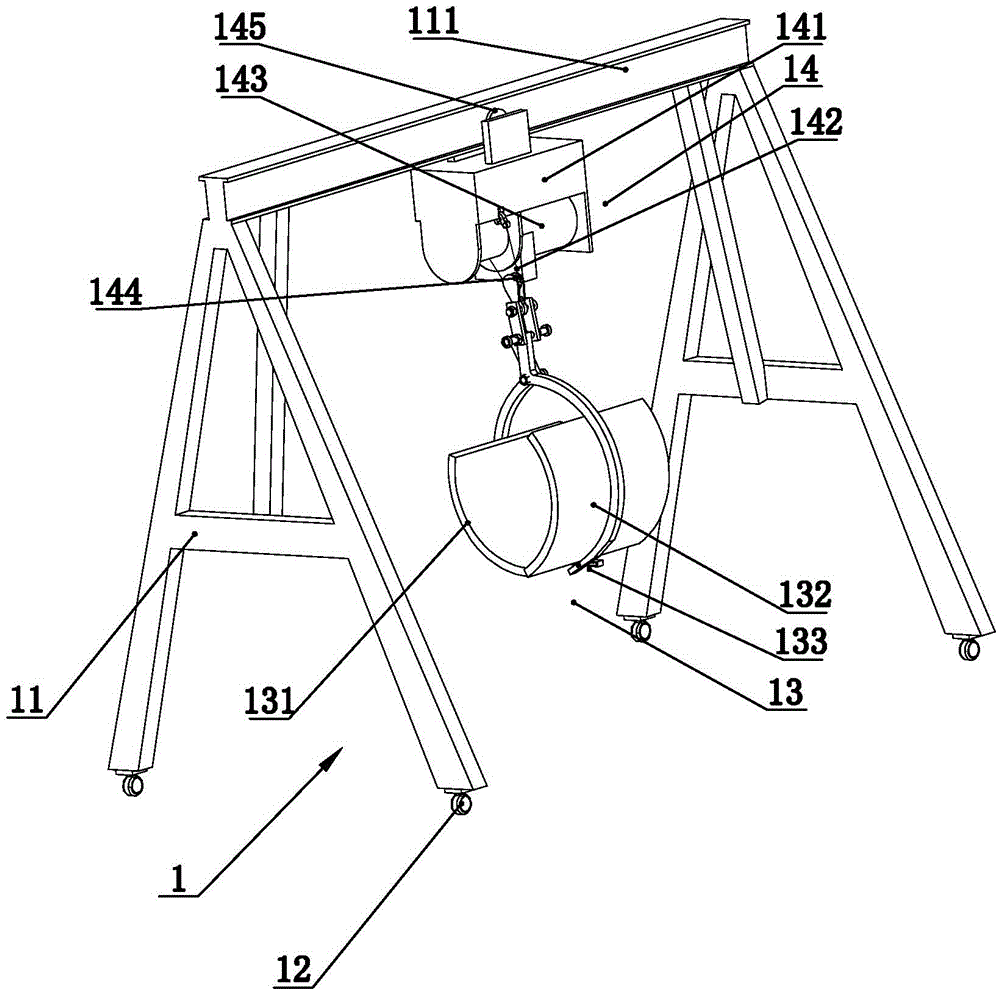

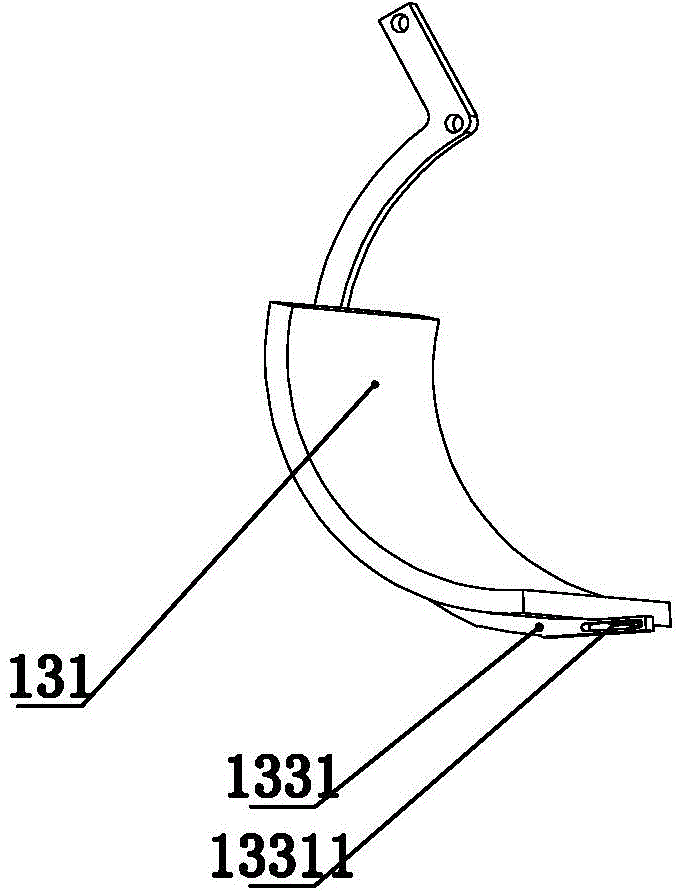

[0026] like Figure 1-6 As shown, a cloth cutting machine includes a cloth tube feeding device 1, a bracket 2, and the bracket 2 is provided with a cloth tube placement frame 3 and a cutting knife frame 4, and the described cutting tool frame 4 is placed on the cloth tube. On the rear side of the frame 3, a pressing roller 5 for pressing the cloth is arranged between the cutting knife frame 4 and the cloth tube placement frame 3, and the pressing roller 5 is arranged horizontally. The rear side of the cutting knife frame 4 Also be provided with material receiving frame 6, described material receiving frame 6 is provided with material receiving shaft 7, and described material receiving shaft 7 is set with some material receiving tubes 8, on the described cutting tool holder 4 corresponding The position between the adjacent receiving barrels 8 is provided with a cutting knife 9, and also includes a driving device for controlling the rotation of the receiving shaft 7. The driving...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap