Leak-proof bridge expansion joint and use method thereof

A technology of expansion joints and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of small elastic waterproof strips, easy fatigue damage, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

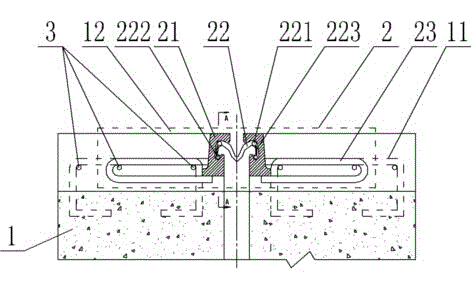

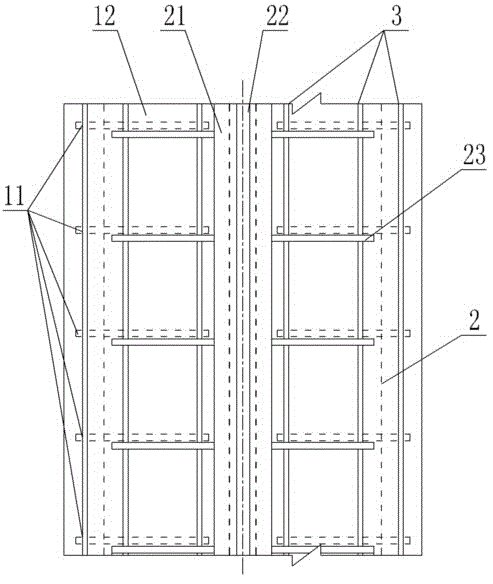

[0101] Example 1 (80mm anti-leakage bridge expansion joint)

[0102] The operation steps of the use method of the anti-seepage bridge expansion joint are as follows:

[0103] ①Making inflatable rubber sealing belt

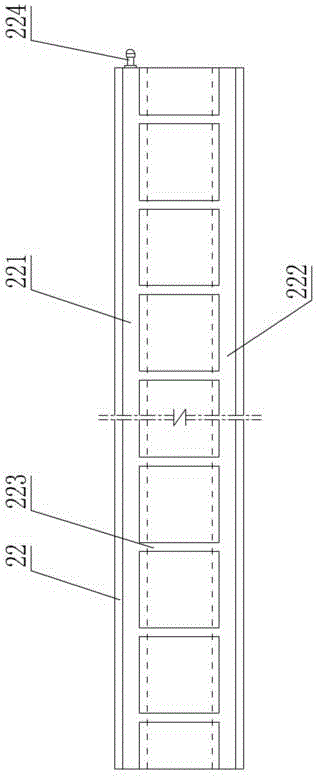

[0104] a. The upper and lower ends of the "M" type rubber sealing belt 22 made of neoprene are respectively made into a circular upper air bag 221 and a lower air bag 222 extending in parallel along the length direction of the rubber sealing belt, Between the upper and lower airbags on the same side of the rubber sealing belt, a communication channel 223 is set at an interval of 20 to 30 mm to make the upper and lower inflatable bags communicate with each other. The diameter of the upper and lower inflatable bags is 6 to 8 mm. The diameter of 223 is 4-6 mm.

[0105] b. Seal one end of the upper inflatable bag 221 along the length direction of the rubber sealing tape 22 , the other end is externally connected to the air valve 224 , and both ends of the lower infla...

Embodiment 2

[0120] Example 2 (40mm anti-seepage bridge expansion joint)

[0121] The operation steps of the use method of the anti-seepage bridge expansion joint are as follows:

[0122] ① Making an inflatable rubber seal

[0123] a, the upper and lower ends of the "M" type rubber sealing belt 22 both sides made of natural rubber are respectively made into a circular upper air bag 221 and a lower air bag 222 extending in parallel along the length direction of the rubber sealing belt. The upper and lower airbags on the same side of the rubber sealing belt are provided with communication channels 223 at intervals of 25 to 35mm so that the upper and lower inflatable bags can communicate with each other. The diameter is 3 ~ 5mm.

[0124] b. Seal one end of the upper inflatable bag 221 along the length direction of the rubber sealing tape 22 , the other end is externally connected to the air valve 224 , and both ends of the lower inflatable bag 222 are sealed.

[0125] ② Install two special...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com