Scroll Compressor

A scroll compressor and scroll technology, applied in the field of compressors, can solve the problems of complex structure, vibration and noise of the upper back pressure scroll compressor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

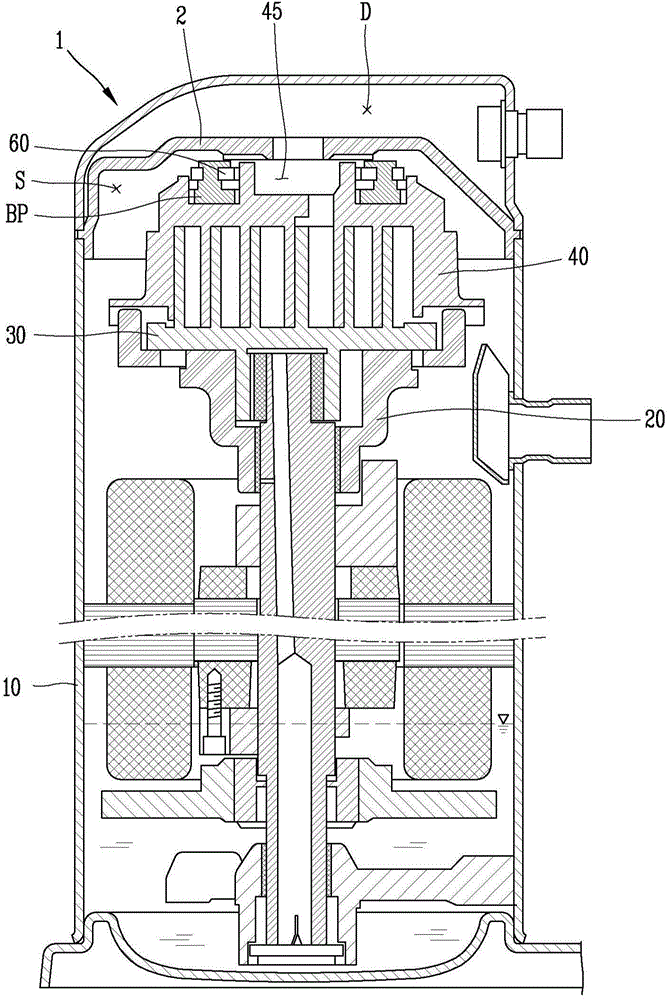

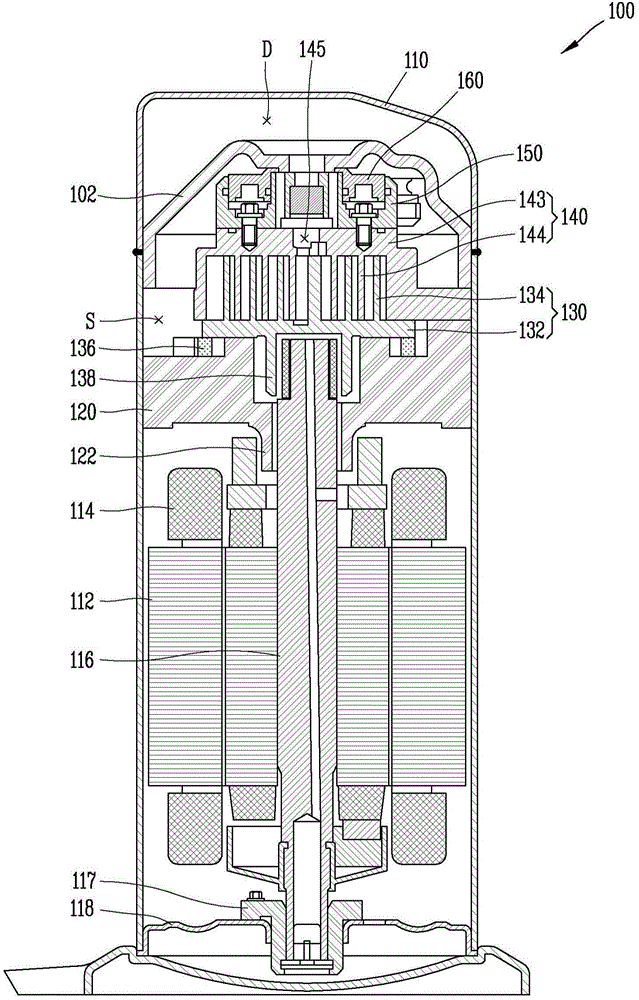

[0045] Referring to the accompanying drawings, a detailed description will now be given of the embodiments. Where possible, like reference numerals are used to designate like elements, and repeated descriptions are omitted.

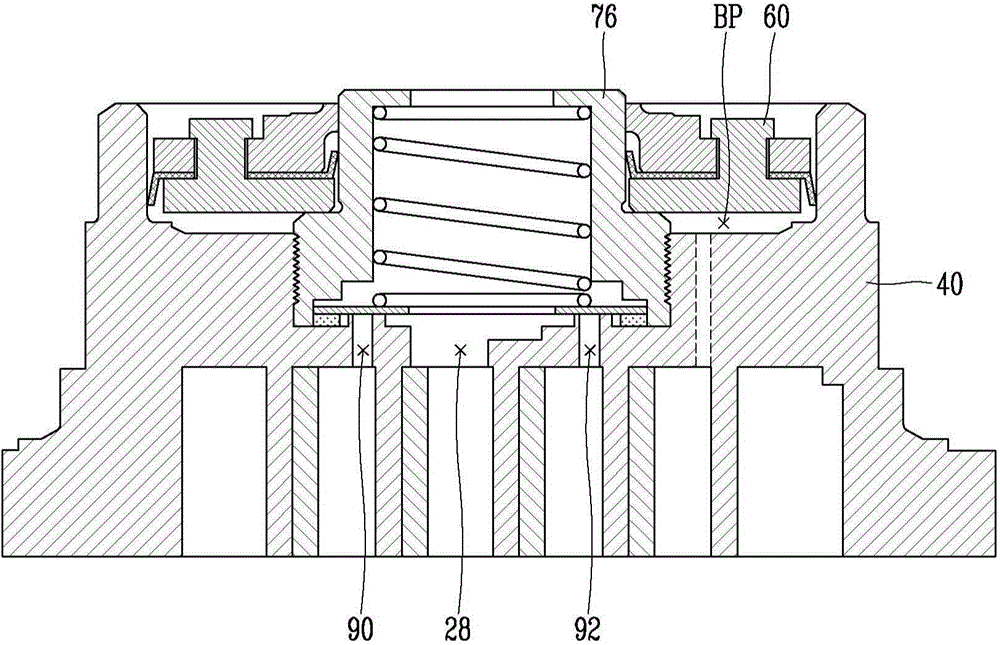

[0046] refer to figure 2 , overloading in upper back pressure type scroll compressors is prevented by using the scroll compressor bypass holes and related components to mitigate pressure imbalances. However, since the hub member 76 can be arranged in the back pressure chamber BP, the positions of the bypass holes 90 , 92 cannot be arbitrarily set. That is, in order to obtain a sufficient back pressure with the back pressure chamber BP, the back pressure chamber BP should be formed in a predetermined size at a predetermined position. This can limit the size of the hub member 76 . Accordingly, the location of the bypass holes 90 , 92 may be limited to the area below the hub member 76 .

[0047] Furthermore, the floating plate 60 should seal the back pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com