Pneumatic self-locking switch valve

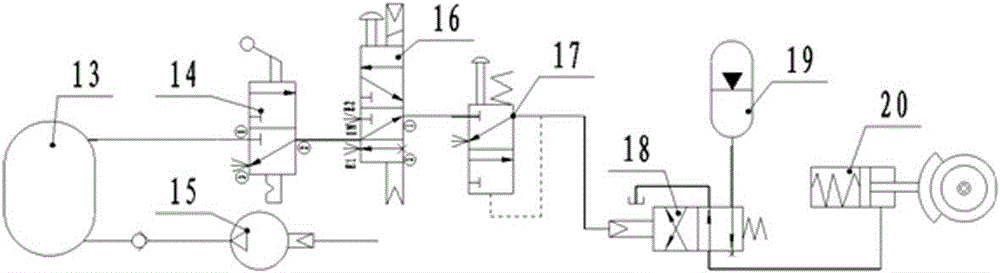

A technology of self-locking switch and spool, which is applied in the direction of control valves, air release valves, brakes, valve details, etc., which can solve the problem that the two-position three-way air-controlled hydraulic reversing valve cannot be reset and cannot realize effective parking brake, The on-off valve cannot be cut off by itself, so as to achieve the effect of strengthening practical value, improving safety and reliability, and working stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

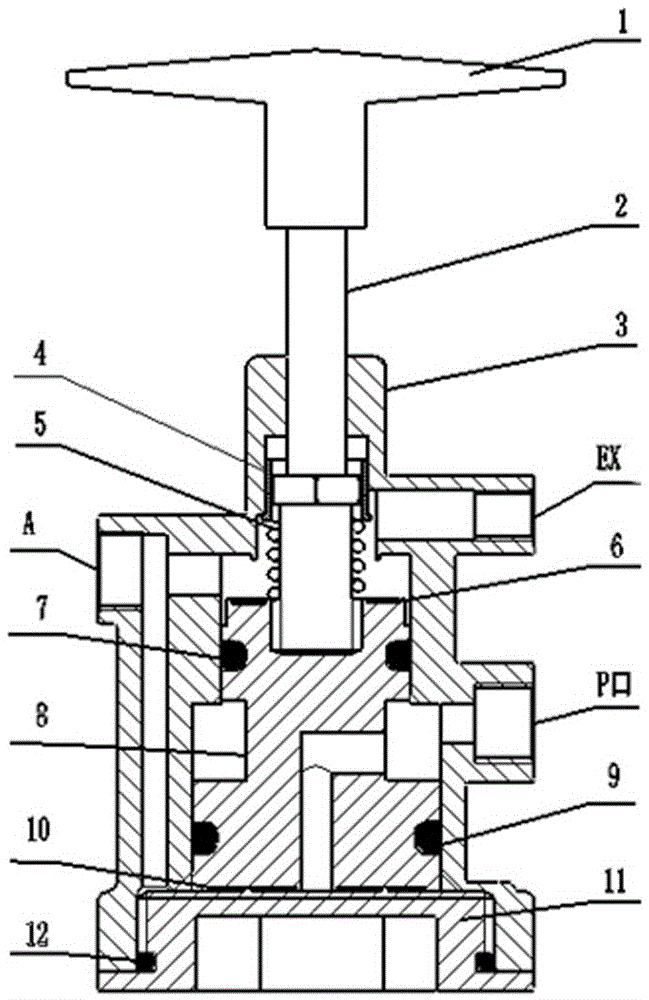

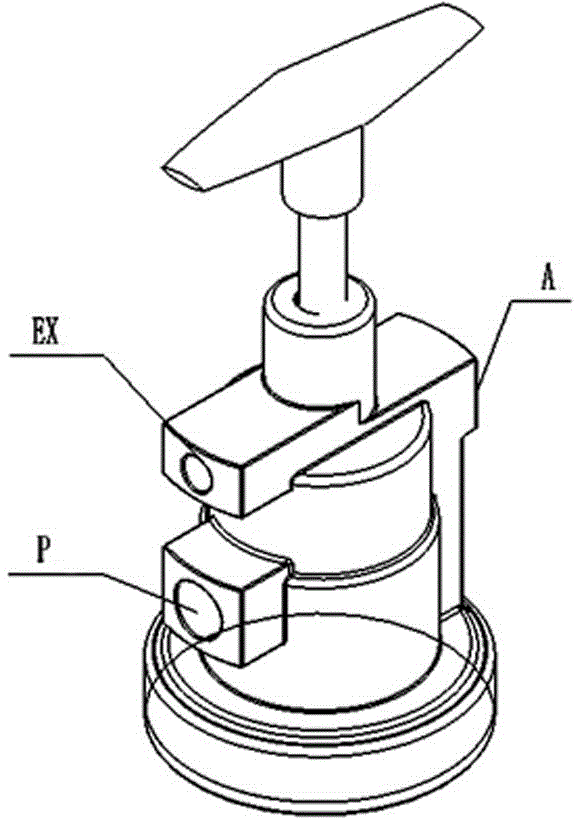

[0020] Such as figure 1 As shown, the pneumatic automatic shut-off valve is mainly composed of handle, valve stem, valve casing, valve core, end cover, sleeve, spring and sealing ring and other components. Valve pressure port P, work port A, exhaust port Ex (such as figure 2 shown) are respectively connected with the gas source, the controlled element and the outside atmosphere.

[0021] The valve core 8 and the valve stem 2 are both circumferentially set in the valve housing 3, and the end cover 11 is connected to the valve housing 3 through threads;

[0022] Three cavities can be formed between the valve core 8, the valve housing 3 and the end cover 11, that is, the spring cavity on the valve stem 2 side of the valve core 8, the middle cavity formed by the middle groove of the valve core 8, and the valve core 8 close to the end cover. Side 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com