Porous asphalt mixture gap blocking experiment method

A technology of asphalt mixture and test method, which is applied in the direction of suspension and porous material analysis, preparation of test samples, and measuring devices, can solve problems such as clogging of void dust particles, achieve improved effect, good promotion and utilization value, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

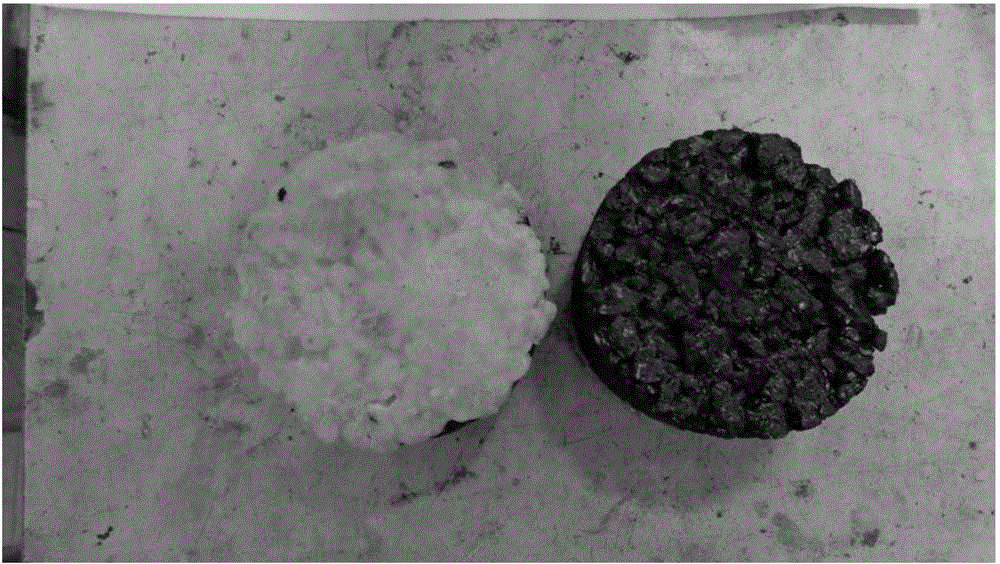

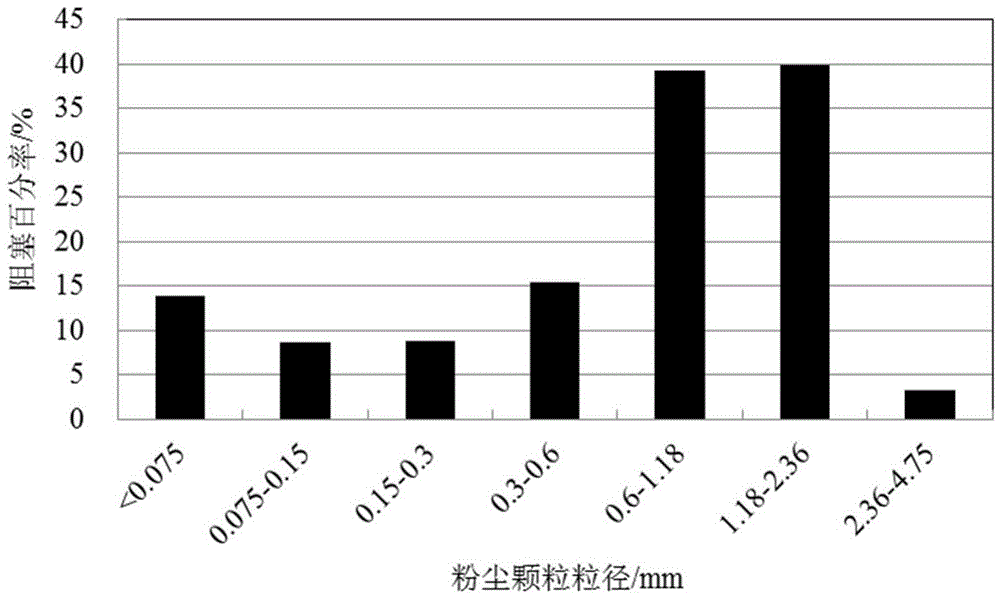

[0039] A porous asphalt mixture pore blocking test method of the present invention has been well tested and verified. The project supported by the test is the porous asphalt pavement section laid between pile numbers K2+900-K3+300 on the south side of Wuzhou Avenue in Shanghai. The porous mixture was mixed indoors and formed according to the designed asphalt ratio, gradation and target design void ratio. Specimen. Apply the test method of this experiment to analyze the clogging of the gaps by different sizes of clogging dust particles. The specific implementation steps are as follows:

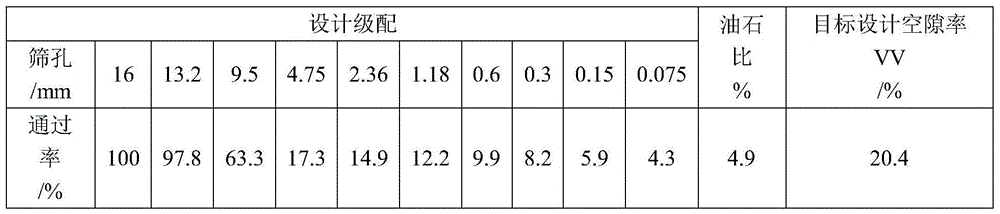

[0040] Step 1: According to the asphalt ratio and gradation of the porous asphalt mixture, according to the T0702-2011 compaction method in JTG E20-2011 of the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", indoor mixing to produce porous asphalt mixture and molding standard Marshall The design gradation, asphalt ratio and target design void ratio of the test piece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com