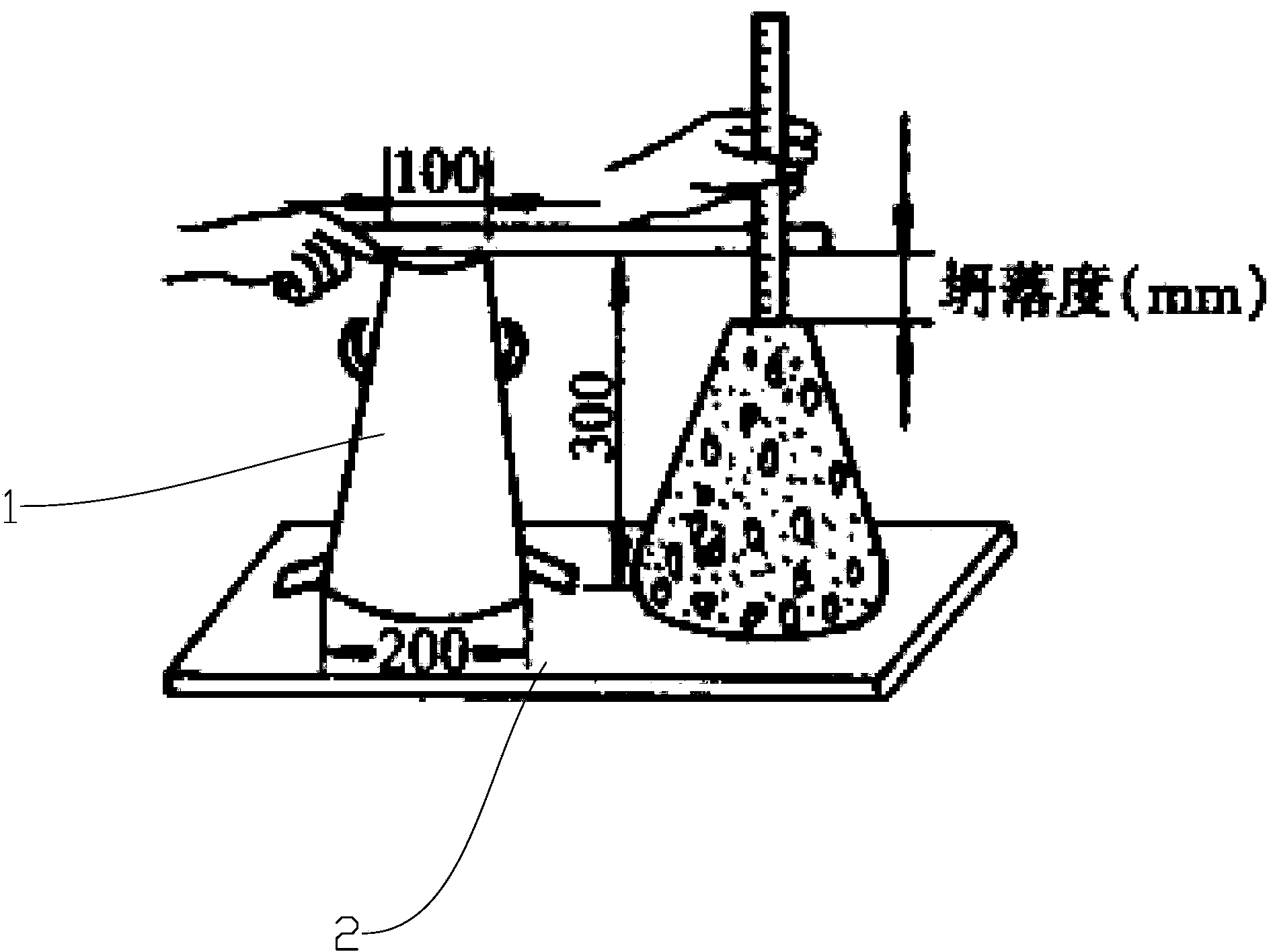

Photoelectric concrete slump tester

A technology of slump and concrete, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as inaccurate slump, actual height error, and inaccuracy, so as to improve the test success rate, ensure accuracy, and avoid The effect of misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

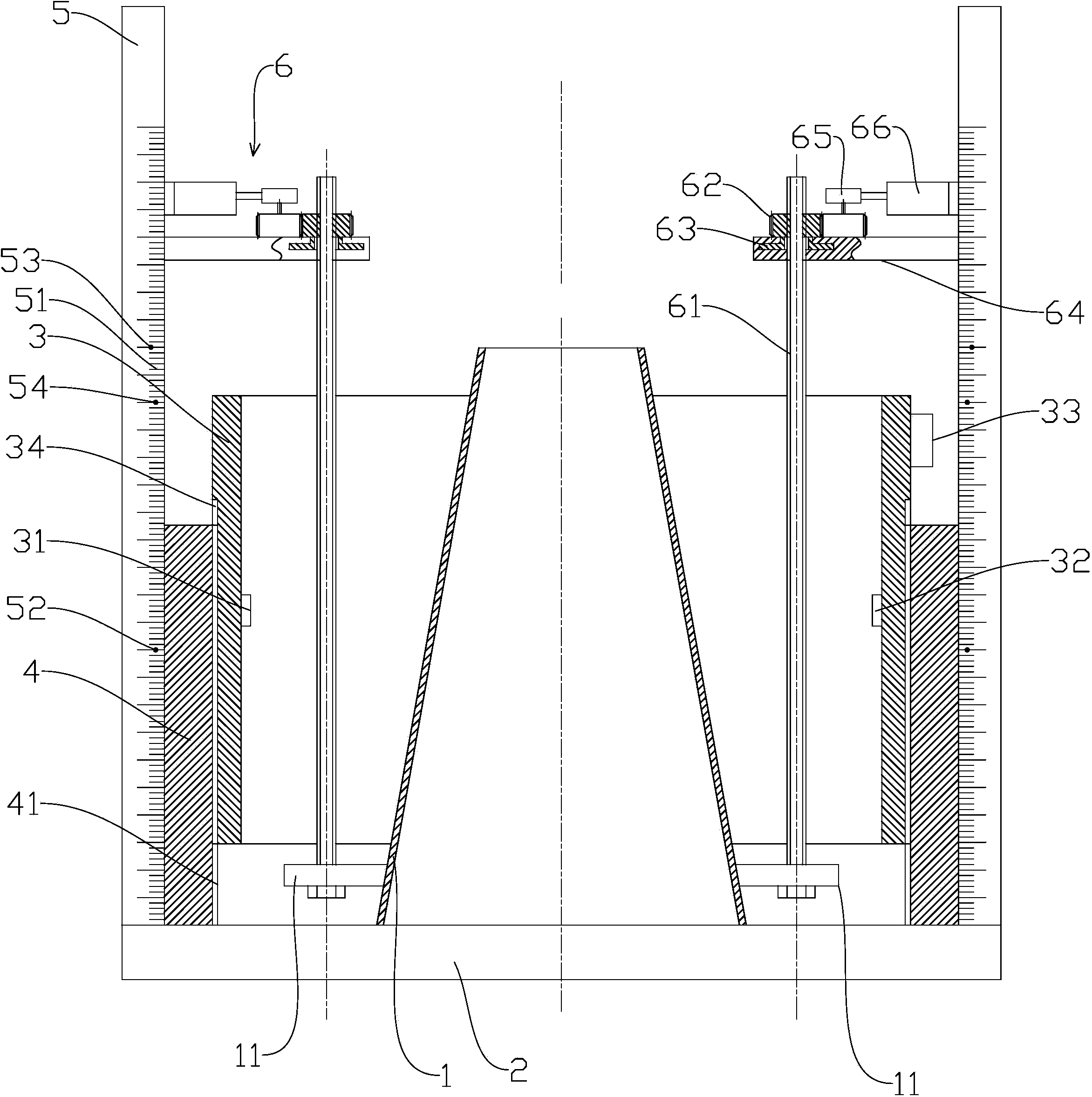

[0022] like figure 2 As shown, the photoelectric concrete slump tester mainly includes a slump cylinder 1, a bottom plate 2, a lifting sleeve 3, a base sleeve 4, a pole 5, and a lifting mechanism.

[0023] The inner diameter of the lifting sleeve 3 is larger than the outer diameter of the slump cylinder 1 . An infrared emitter 31 and an infrared receiver 32 are arranged on the inner surface of the lifting sleeve 3, and the infrared emitter 31 and the infrared receiver 32 are arranged at the same horizontal position. The outer surface of the lifting sleeve 3 is provided with an infrared receiving prompter 33 that sends out prompt information when the infrared receiver receives infrared rays, and the infrared receiving prompter 33 is connected with the infrared receiver 32 . A section of external thread 34 is provided on the outer surface of the lifting sleeve 3 .

[0024] The lifting sleeve 3 is mated with the internal thread 41 of a base sleeve 4 through the external thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com