Ball mill impact force detection device and impact force detection and ball mill speed regulation method

A detection device and ball mill technology, applied in grain processing and other directions, can solve the problems of no detection means and no detection equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

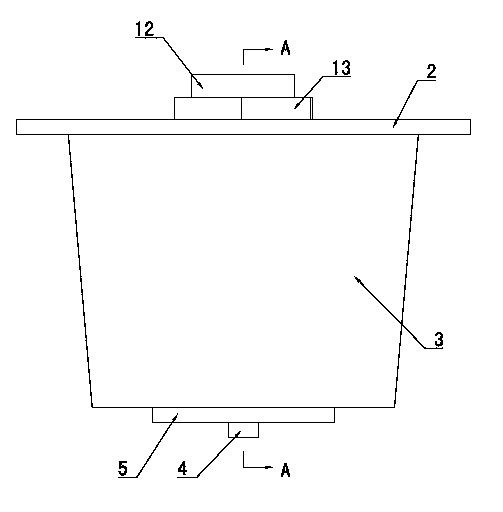

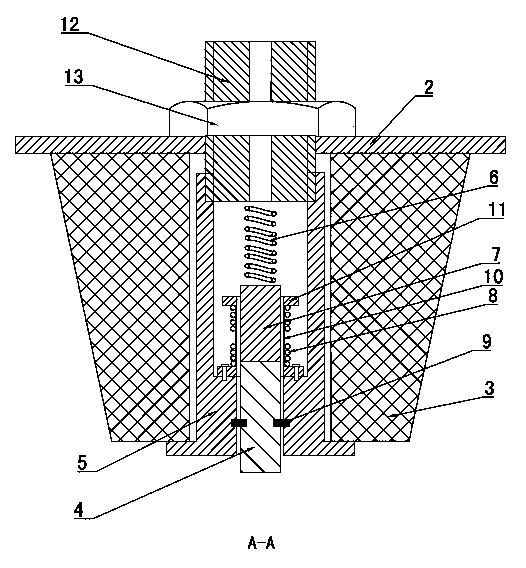

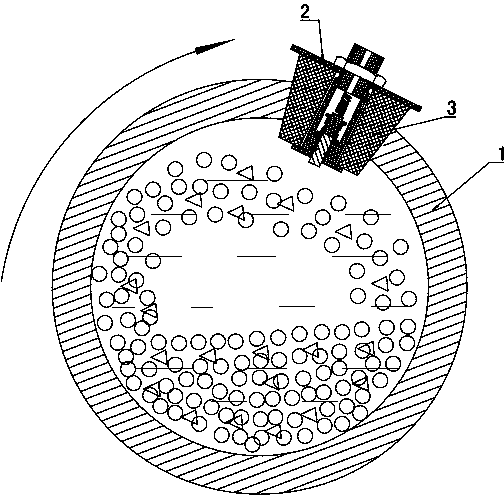

[0039] Figure 1~4 It is the best embodiment of the ball mill impact detection device, below in conjunction with the attached Figure 1~4 The impact force detection device of the ball mill, the impact force detection and the speed regulation method of the ball mill are further explained.

[0040] Refer to attached Figure 1-3 : the ball mill impact detection device is installed in the opening of the ball mill 1, and the ball mill 1 is driven to rotate by a variable frequency motor 14. Including the ball mill cover 2, the protective head 3 and the detection rod 4, the lower part of the ball mill cover 2 is provided with the protective head 3 which can be inserted into the opening of the ball mill 1, and the protective head 3 is a cylindrical structure with a taper on the outer ring so that it can be inserted into the ball mill In the opening of 1, the protective head 3 is made of elastic rubber or plastic material, which can buffer the impact of ball stones and ore raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com