Machining technology method of sealing surface

A technology of processing technology and sealing surface, which is applied in the field of processing technology of oil inlet and outlet, can solve the problems of reducing processing speed, milling cutter wear, increasing cost, etc., and achieves the effects of enhanced sealing effect, small tool wear and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

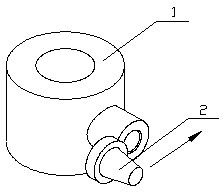

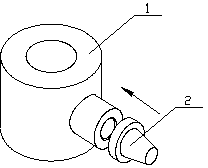

[0009] The processing method of sealing surface of the present invention is as figure 2 As shown, the feeding direction of the milling cutter 2 is from top to bottom along the direction of the arrow. The processing traces formed by this processing method are circles that diffuse from the inside to the outside. After the traces are generated, peaks and valleys are formed on the sealing surface. The phenomenon of alternating appearance forms a sawtooth structure, which makes the sealing contact area of the sealing surface larger, thereby greatly enhancing the sealing effect. This method is characterized by fast processing speed and low tool wear. It improves the processing efficiency and the good sealing performance of the sealing surface while retaining all the original advantages, so as to achieve the purpose of saving costs, improving efficiency and product quality.

[0010] The present invention has been described by means of embodiments, and those skilled in the art will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com