Preassembling method for anchor mouth of bulk frighter in segmentation stage

A technology of anchor lip and cargo ship, which is applied in the segmented pre-installation field of bulk carrier anchor lip, can solve problems such as positioning errors, and achieve the effects of saving installation costs, avoiding deviations in installation accuracy and subsequent modifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

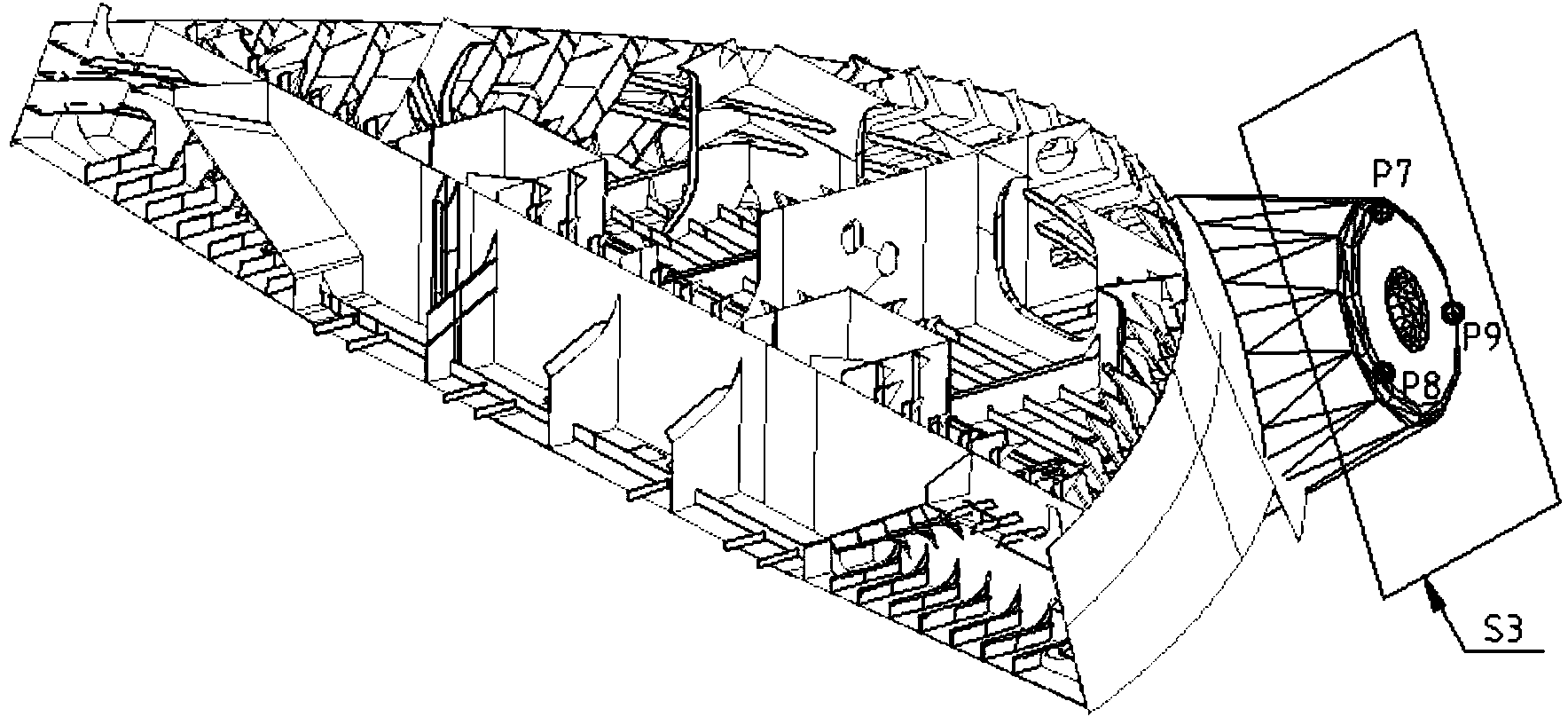

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

[0019] A method for preinstalling an anchor lip of a bulk carrier in stages, comprising the following steps:

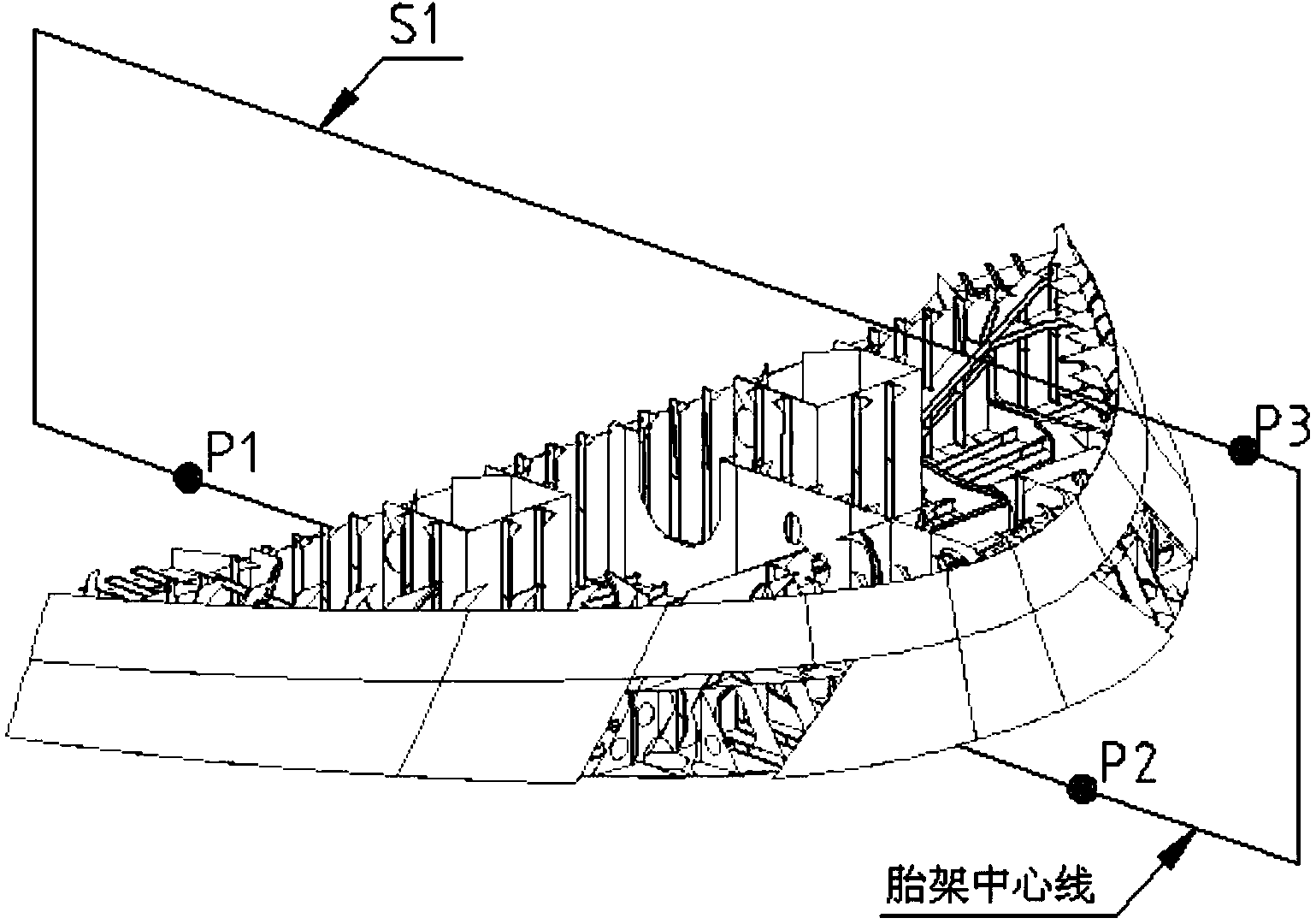

[0020] ①Using the deck as the base plane, place the anchor lip segments of the bulk carrier on the horizontal tire frame in reverse state, find out any two points P1 and P2 on the center line of the tire frame ground, and use the total station to measure the two points P1 and P2 to determine A straight line L1, determine a point P3 on the vertical plane of the straight line L1, make the vertical projection point of the point P3 fall on the straight line L1, and create a vertical plane S1 parallel to the longitudinal section of the hull through the points P1, P2 and P3, see figure 1 .

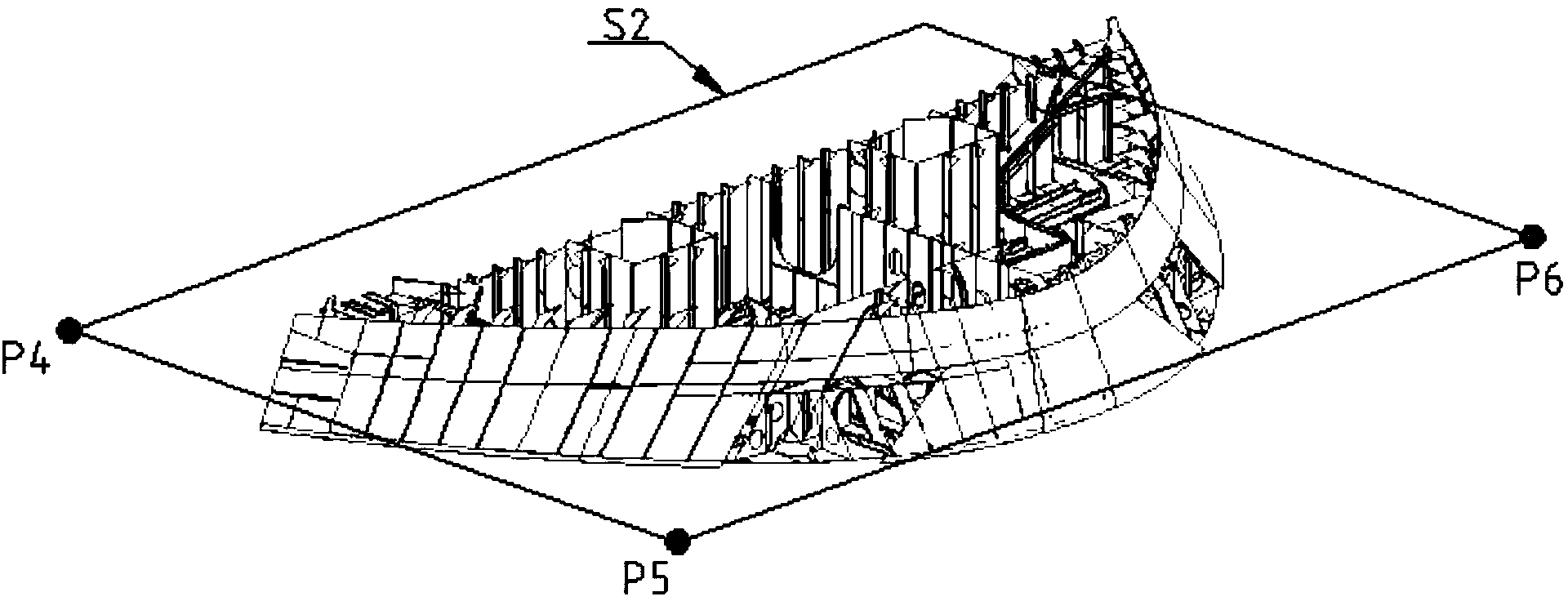

[0021] ②Use the total station to arbitrarily determine a point P4 in the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com