Opening convenient to screw in cap

A technology of bottle caps and threaded teeth, which is applied in the field of bottle caps that are easy to screw in, and can solve problems such as the difficulty of convex teeth entering the convex tooth screw inlet, low processing precision of bottle caps and bottle mouths, and too tight snap-in, etc. achieve a reasonable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

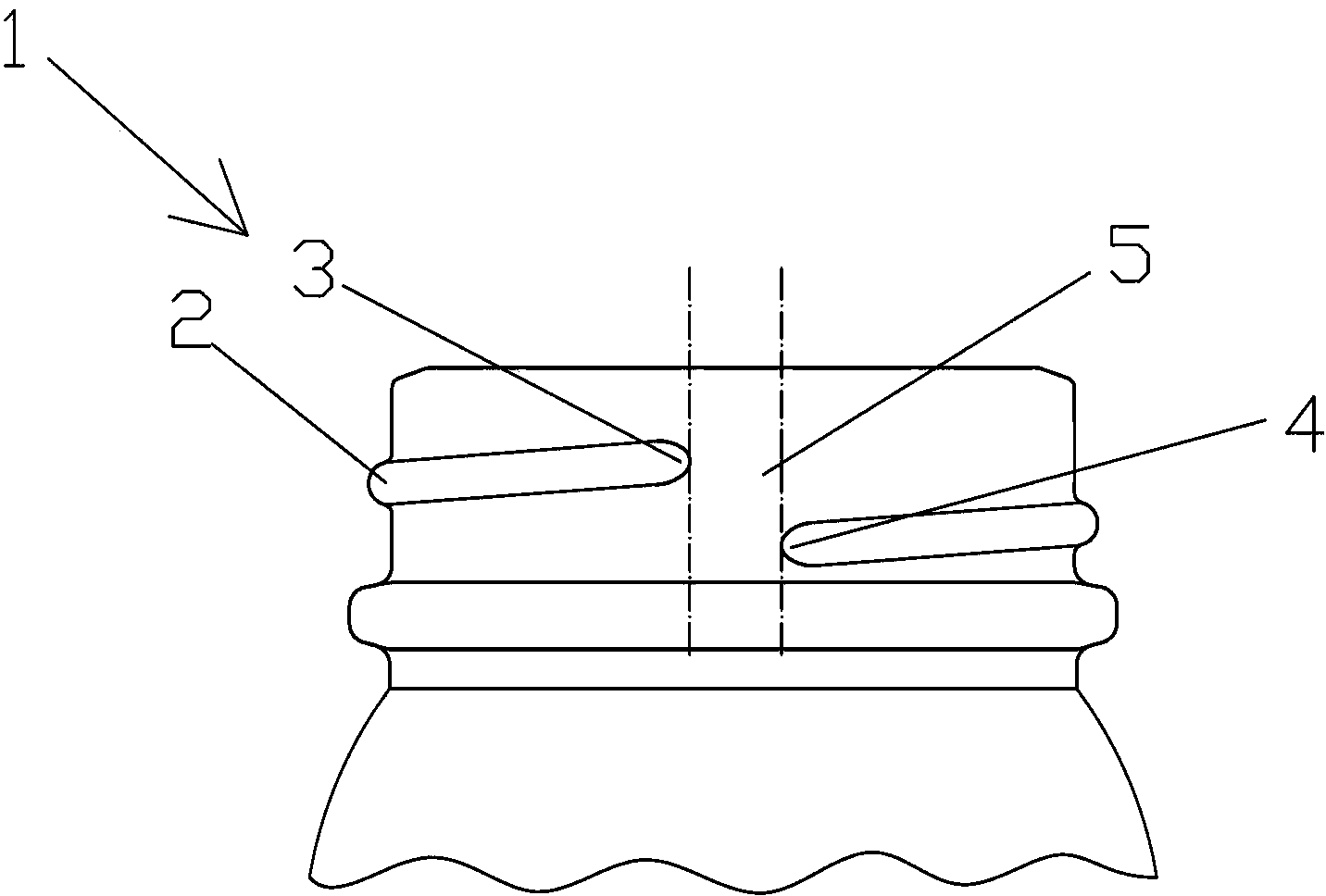

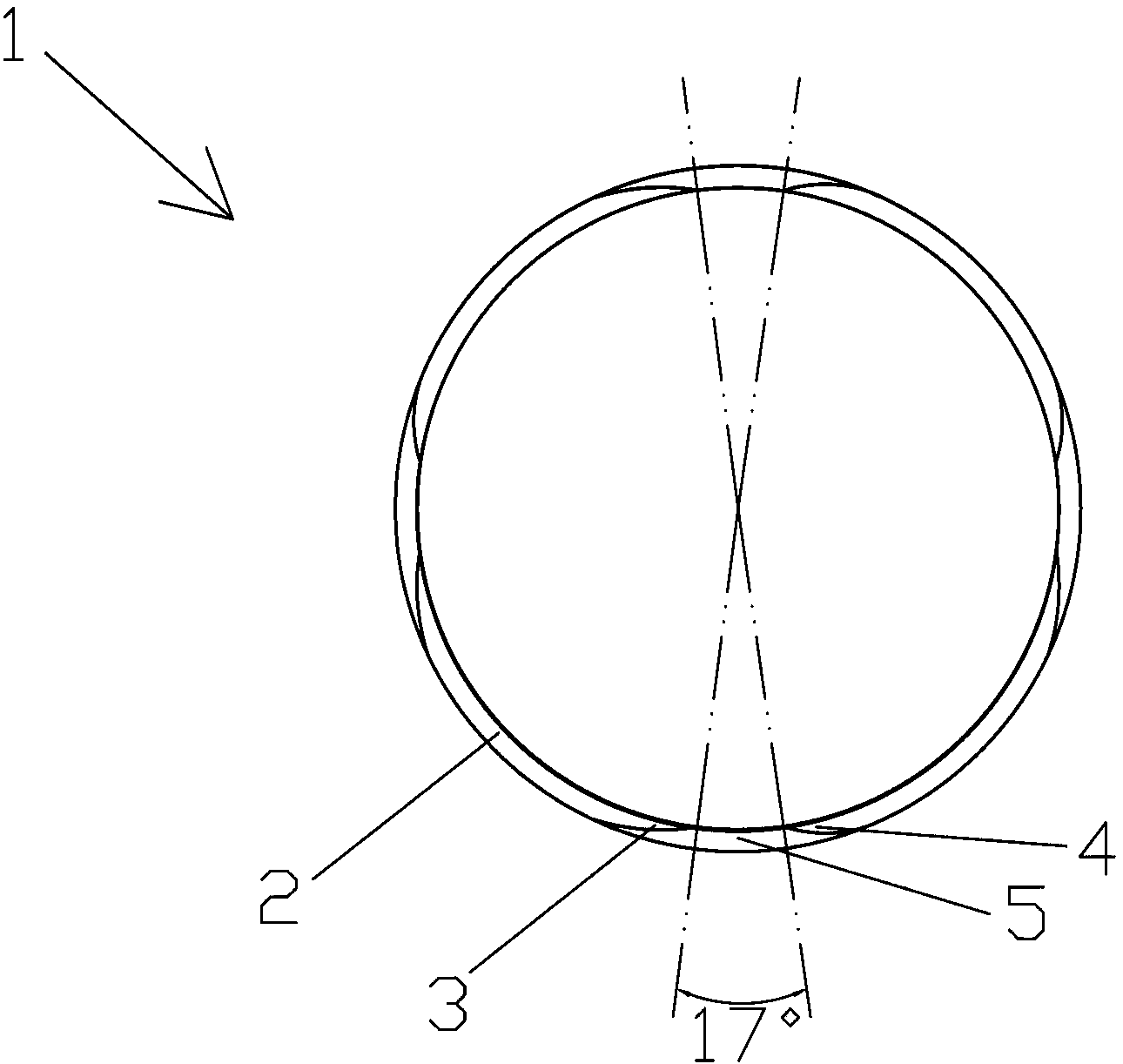

[0016] Embodiment: a kind of bottleneck that is convenient to bottle cap screwing in, as Figure 1-2 As shown, it includes a bottle mouth 1 and four inclined thread teeth 2 evenly arranged on the outer ring of the bottle mouth 1, each thread thread 2 includes a start 3 and an end 4, and the start 3 of any thread 2 is connected to the adjacent thread The ends 4 of the teeth 2 are staggered to leave a space 5 left and right.

[0017] Specifically, in the horizontal direction, the central angle of the arc corresponding to the left and right intervals is 17°. If this ratio is set, the guiding function of the inclined thread 2 is played, and the convex teeth can be more stably buckled on the thread. 2 below; the angle formed by the inclined threaded teeth 2 relative to the horizontal plane is 10°; the number of said threaded teeth 2 is 4, and each threaded tooth 2 is matched with a protruding tooth respectively, between the bottle cap and the bottle mouth 1 Very stable.

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com