Split ring with internal thread

A split ring and internal thread technology, which is applied in the field of split rings, can solve the problems of gas or liquid leakage in the connecting pipeline, loosening of the connecting pipeline, etc., to avoid gas or liquid leakage, large adjustment, wear resistance and sealing performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

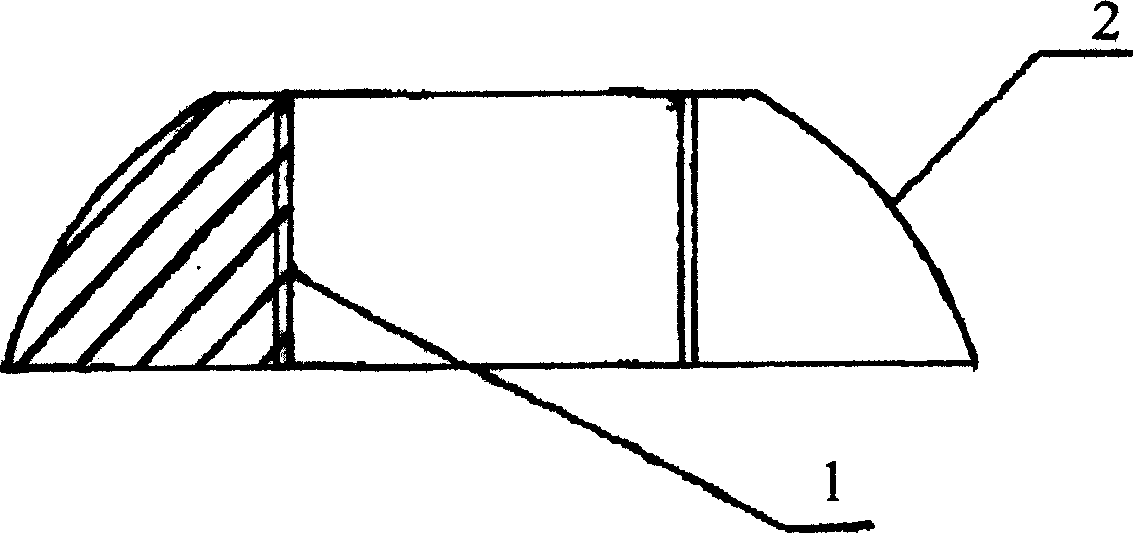

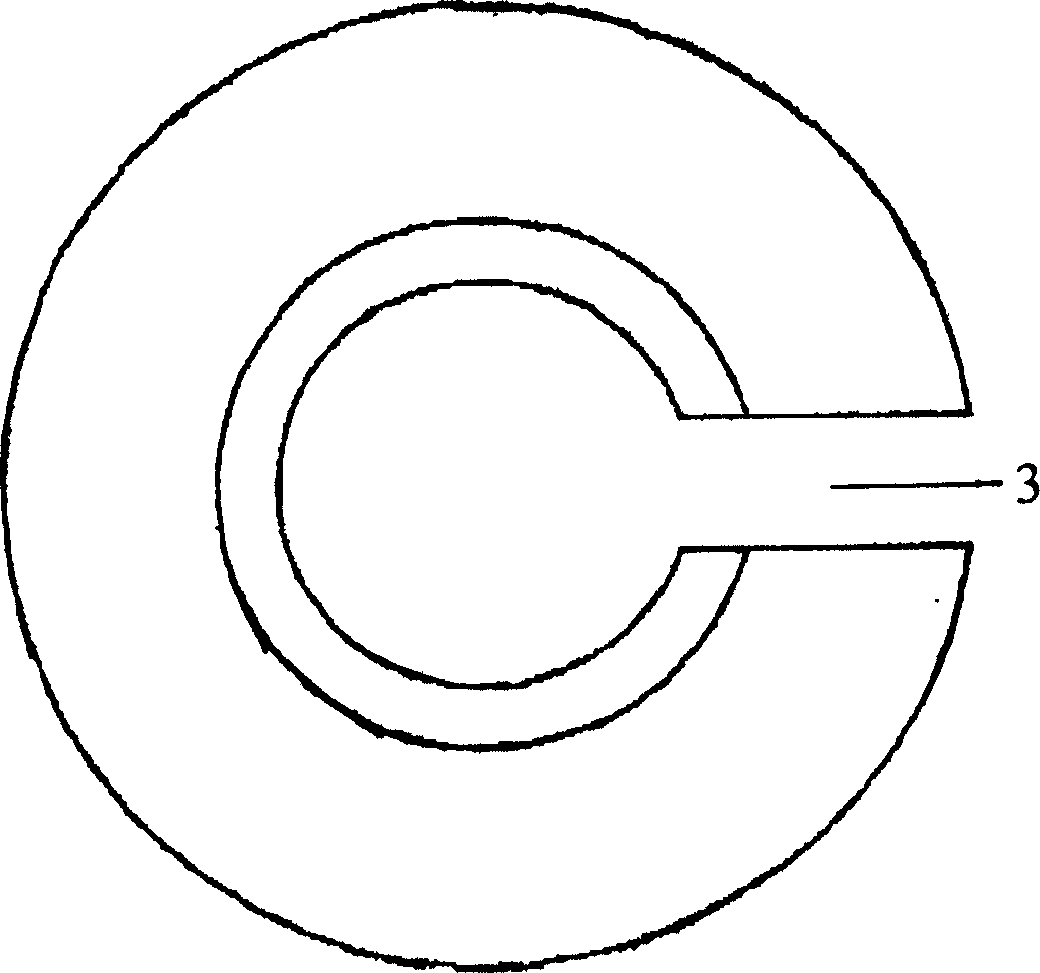

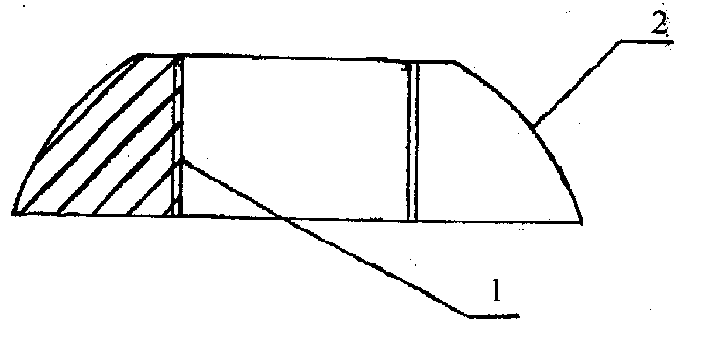

[0014] See figure 1 and 2 . Stainless steel ring material is used, the inner surface of the ring is tapped with metric threads 1 , the outer surface of the ring is processed into a spherical shape 2 , and an opening 3 is formed by truncating the ring body perpendicular to the lower plane.

[0015] Put the lock nut with internal thread on the outside of the connected pipe, the processed split ring of the present invention is placed outside the pipe and in the lock nut, and then further install the gasket and O-shaped rubber sealing ring, the lock nut and Fitting with pipe joints with external threads, since the split ring is a spherical ring, the split ring is squeezed by rotating the lock nut, so that the opening of the split ring is gradually reduced, and the pipes are firmly connected; and because the split ring contacts The surface is metric thread, which can strengthen the locking force with the outer surface of the connected pipe and prevent the connecting pipe from loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com