Assembly type hollow slab bridge and construction method thereof

A technology of hollow slab bridges and hollow slabs, which is applied in the direction of erecting/assembling bridges, bridge construction, bridges, etc., which can solve the problems of low strength of grooved concrete, poor bridge integrity, and difficult quality assurance, etc., and achieve steel plate force transmission Clarify and simplify the support process, and the effect of mature design calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

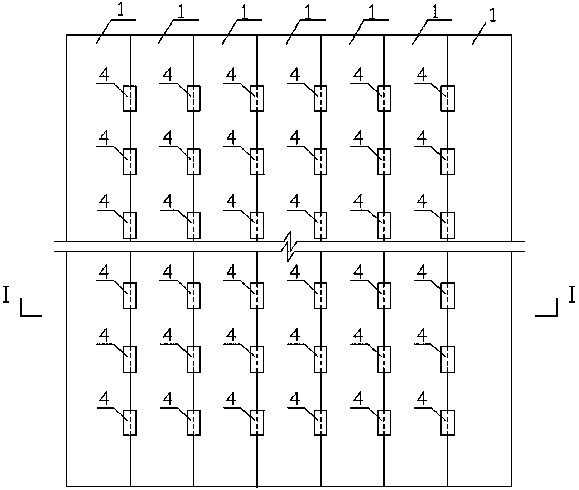

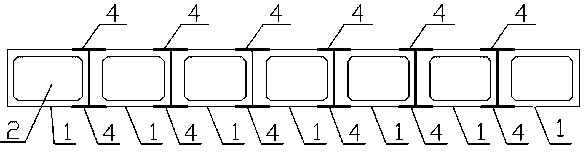

[0020] Depend on Figure 1-Figure 3 The assembled hollow slab bridge shown includes hollow slabs 1 arranged continuously from left to right in the transverse direction. The hollow slabs 1 extend longitudinally from front to back and are pre-tensioned. The body of the hollow plate 1 is provided with an inner hole 2 extending longitudinally. The longitudinal sides of the hollow plate 1 are straight sides, and all the sides of the hollow plate 1 are straight sides. The longitudinal extension of the hollow plate 1 The sides of the hollow plate 1 are straight, that is, the longitudinally extending sides of the hollow plate 1 are perpendicular to the upper and lower surfaces of the hollow plate 1 . The longitudinal direction is the length direction of the hollow plate 1 , and the transverse direction is the width direction of the hollow plate 1 . Certainly, the application of the present invention is not limited to the above-mentioned form, and two inner holes of each hollow pla...

Embodiment 2

[0023] The construction method of the prefabricated hollow slab bridge is aimed at the construction method of the prefabricated hollow slab bridge adopting steel plate plug-in connection described in embodiment 1, and it comprises the following steps:

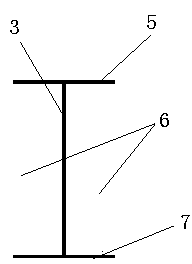

[0024] (1) Prepare the hollow plate 1 and the I-beam 4 described in Example 1: process the prefabricated I-beam 4 according to the predetermined size, the height of the web 3 of the I-beam 4 corresponds to the thickness of the hollow plate 1; the hollow plate 1 During fabrication, the structural analysis of the hollow slab bridge is first carried out according to the design parameters such as bridge grade, span, and bridge deck width, and the cross-sectional size, ordinary steel bars and longitudinal prestressed tendons of the hollow slab 1 are calculated and determined, and the shear resistance between adjacent girders and slabs is determined. The design requires calculation and determination of the structural size, steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com