A vertical or horizontal component assembly structure of an aluminum-clad wood sun room

A technology of transverse components and assembly structures, which is applied in the direction of building construction and construction, and can solve the problems of being susceptible to moisture, deformation and corrosion, poor assembly quality, and insufficient compactness, achieving good air tightness and thermal insulation performance, and reducing processing workload , Easy and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

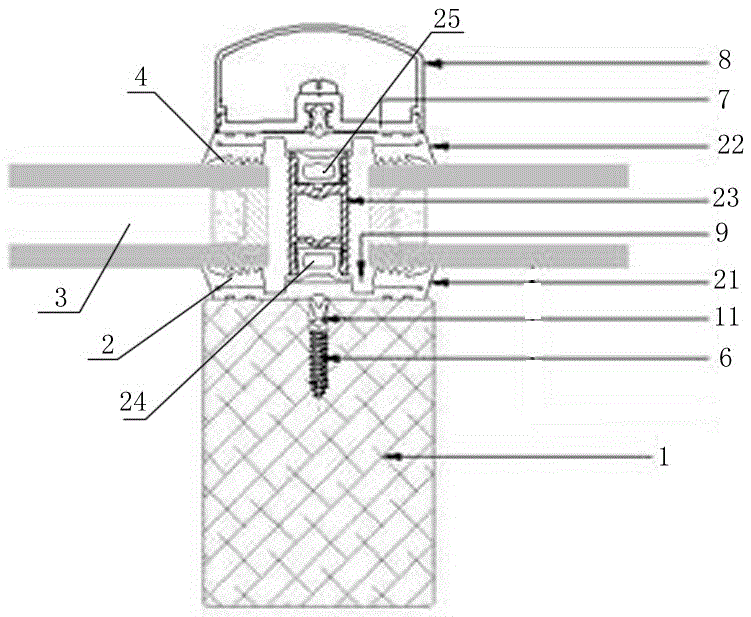

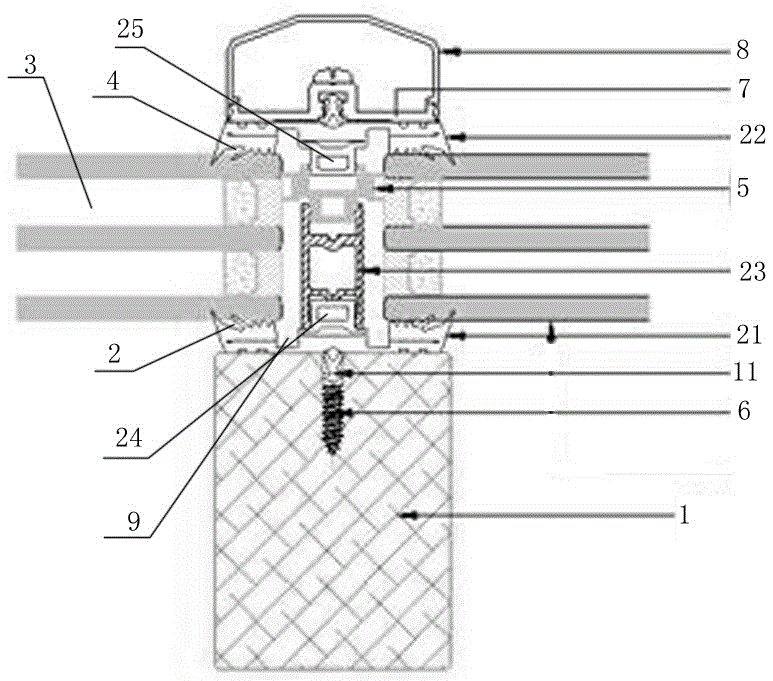

[0012] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the vertical or transverse component assembly structure of the aluminum-clad wood sun room according to the present invention includes a column 1 or a crosspiece made of wood-glued wood, and the end of the column 1 or crosspiece is fixed with The adhesive strip assembly 2, and the lateral sides of the adhesive strip assembly are respectively formed with embedding grooves 4 on the same surface, which can clamp the hollow glass 3.

[0013] As shown in the figure, the rubber strip assembly 2 is mainly composed of an inner rubber strip 21, an outer rubber strip 22 and a PVC profile 23 connected in the middle, and the ends of the columns 1 or crosspieces are fixed through the rubber strip connecting groove 11 There is an inner rubber strip 21, and the middle of the inner rubber strip 21 is provided with an inner rubber strip clamping convex groove 24, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com