Lens-barrel sliding block, focusing lens, image collecting equipment, controller and control method

A technology of focusing lens and controller, applied in the field of communication, can solve the problems of motor heating, motor gear set wear, gear set wear and other problems, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

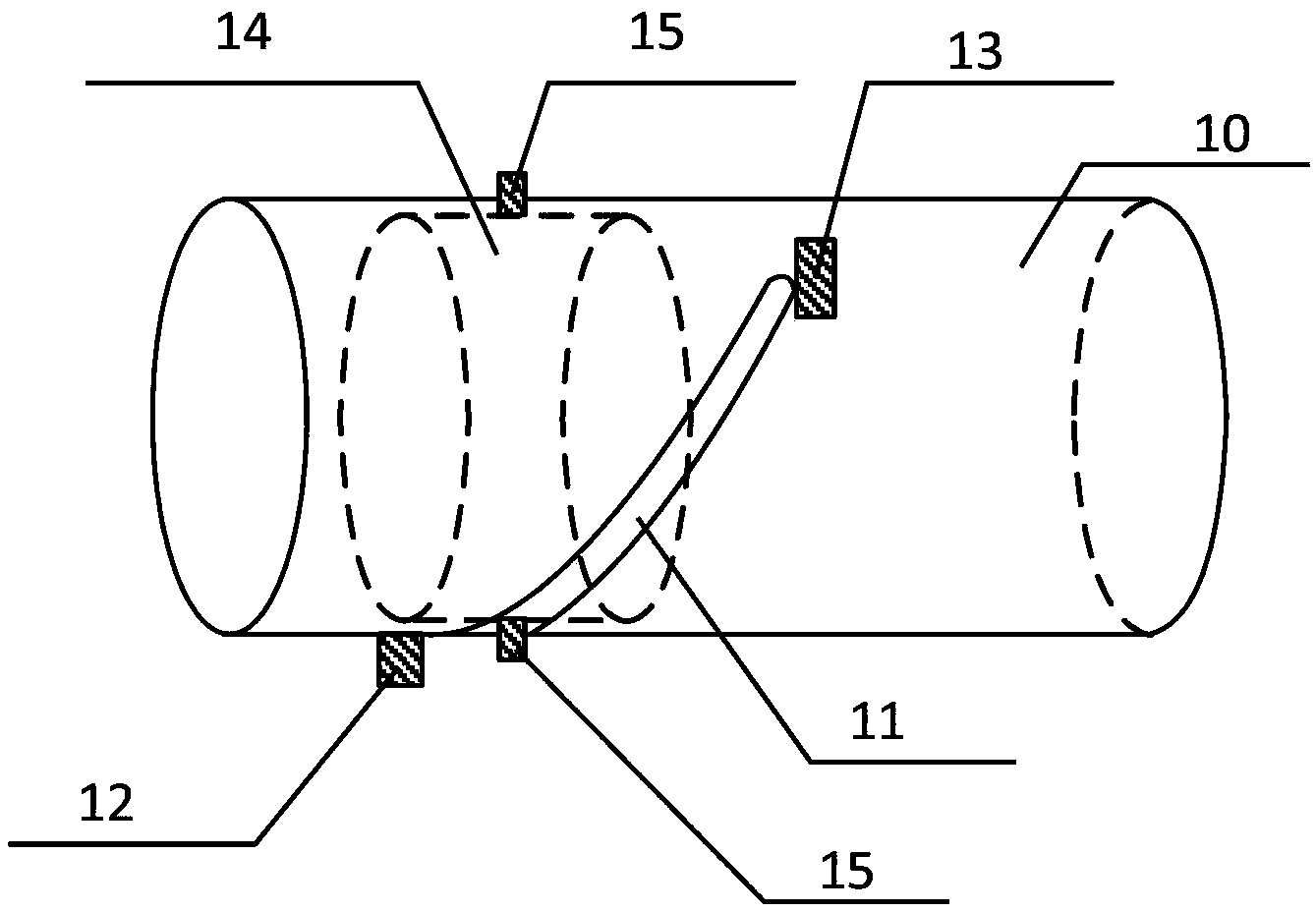

[0030] Embodiments of the present invention provide a lens barrel slider, a synchronous focusing lens, an image acquisition device, a controller and a control method thereof.

[0031] In the embodiment of the present invention, through simple motion stroke detection, when the lens group (including the zoom lens group and the zoom lens group) reaches the limit position, the stop motor continues to run in the same direction, thereby avoiding abnormal behaviors that cause damage to the synchronous focus lens.

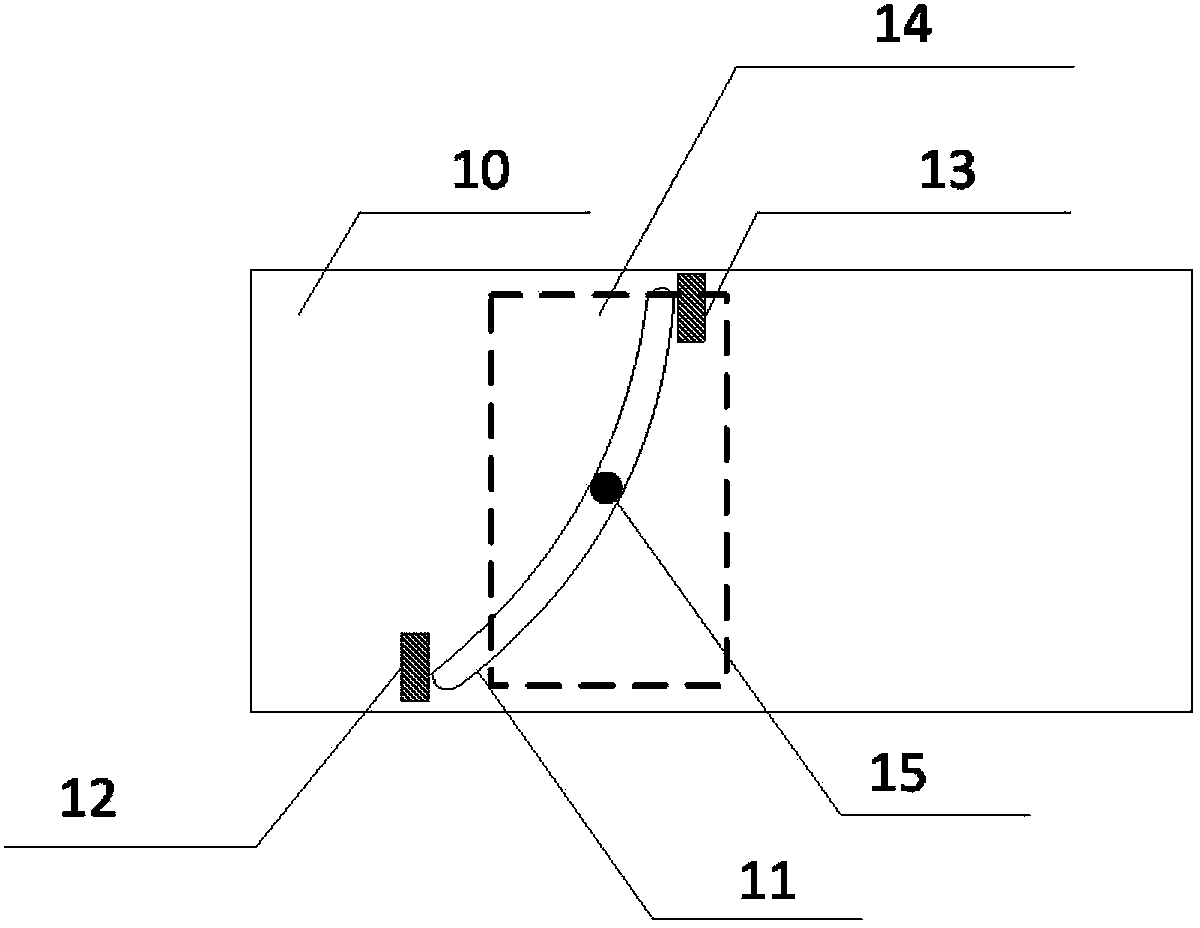

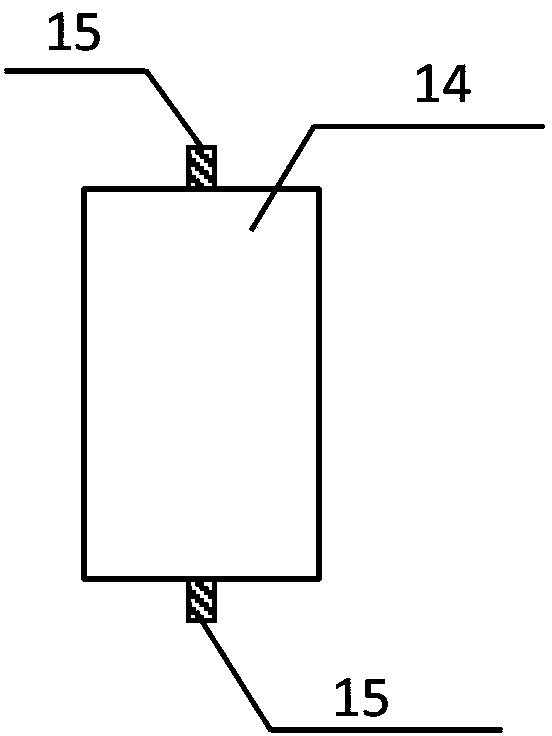

[0032] A lens barrel slider provided by an embodiment of the present invention includes a hollow cylindrical barrel, a first chute and a second chute arranged on the inner wall of the hollow cylindrical barrel, wherein the first chute is the chute of the zoom lens group , the second chute is the chute of the zoom lens group, at least one end of the first chute and / or the second chute is provided with a tact switch, wherein when the tact switch is touched, the tact switch T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com