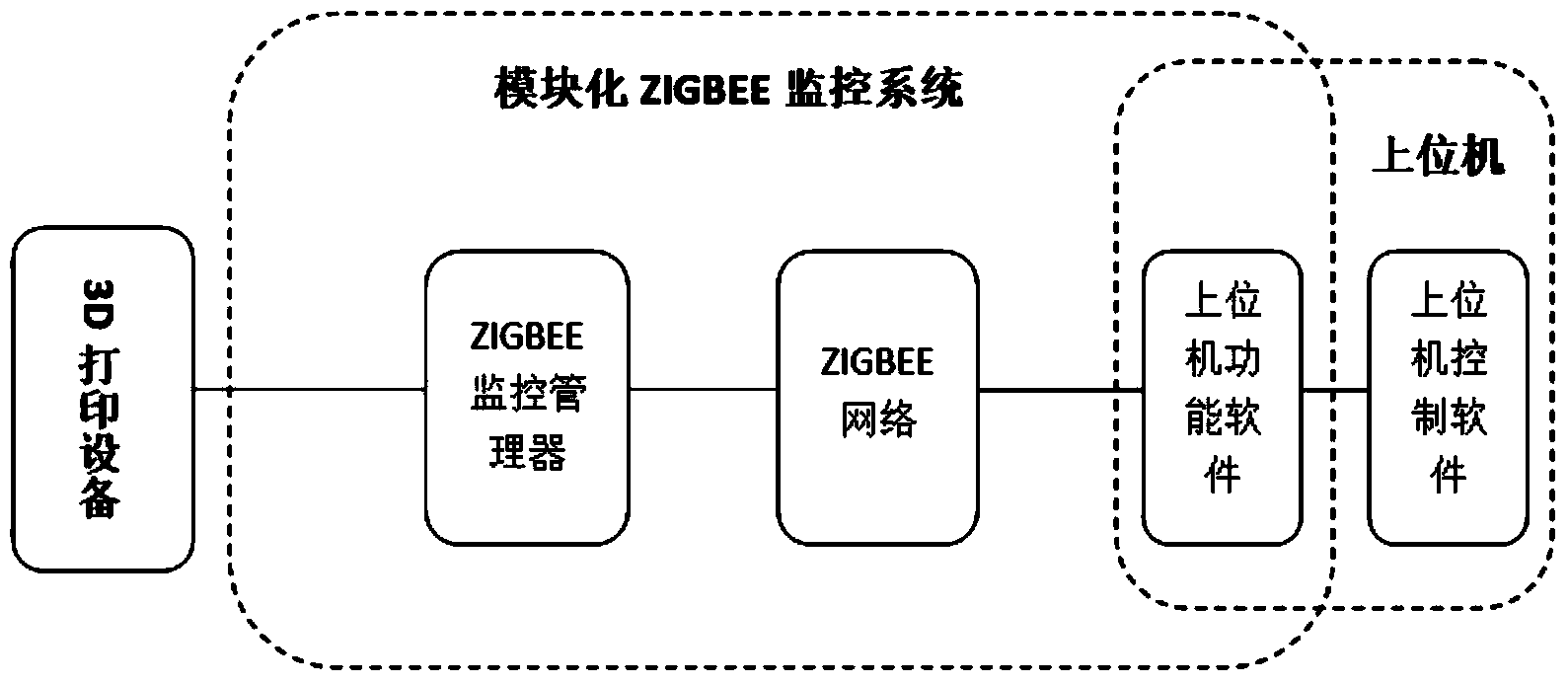

Modularized Zigbee monitoring system applied to 3D printing equipment

A 3D printing and monitoring system technology, applied in the field of communication systems, can solve the problems that the performance of equipment cannot be further developed, and achieve the effects of long processing time, high environmental requirements, and geographical dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

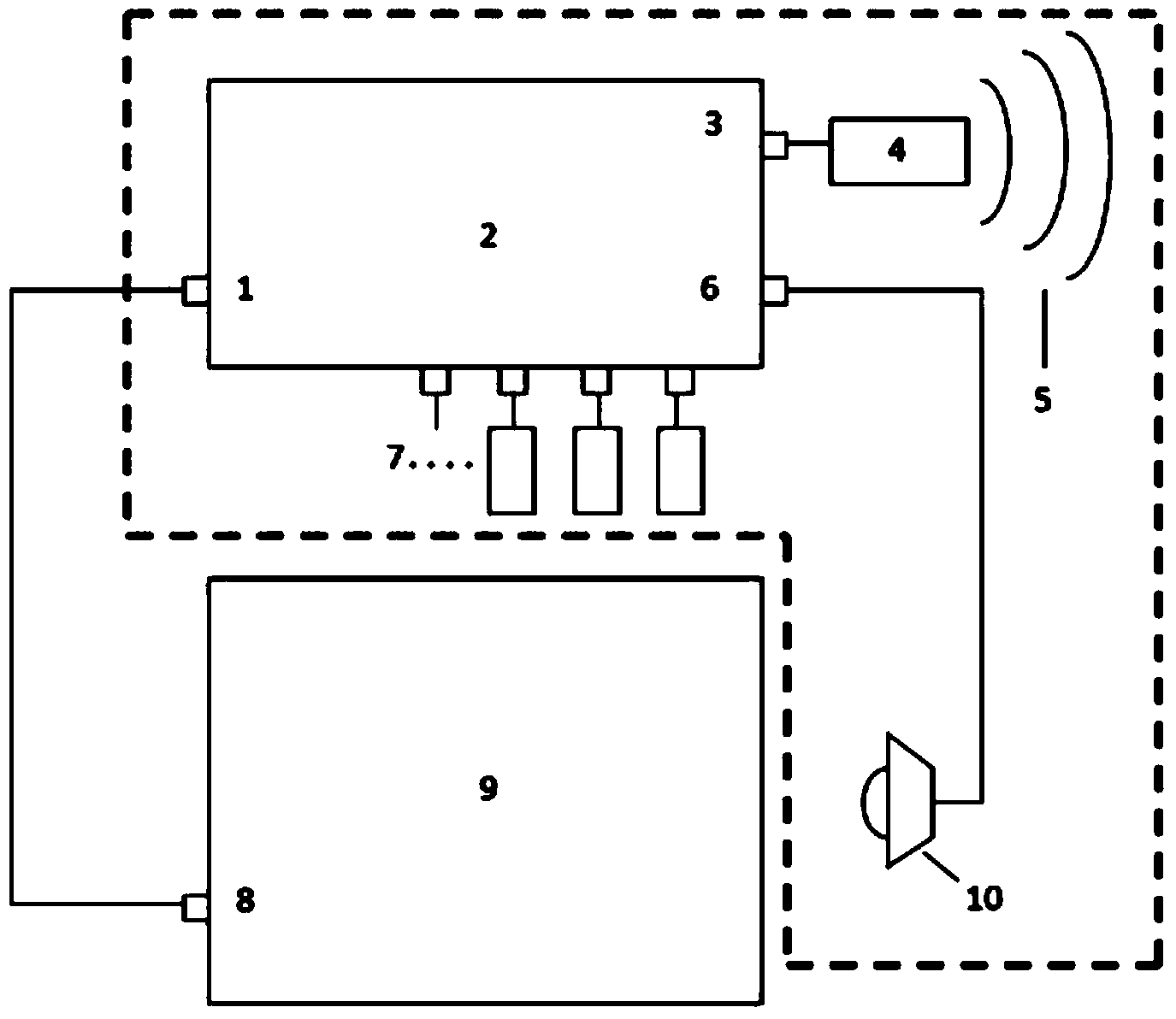

[0026] ZigBee is a low-power LAN protocol based on the IEEE802.15.4 standard. ZigBee is characterized by ad hoc networking and low power consumption, and is especially suitable for industrial production. The ad-hoc network means that each node of the ZIGBEE network can perform the functions of uploading, uploading, uploading and transferring at the same time. That is to say, the ZIGBEE network does not need to arrange a separate router to build the network like a WIFI network. Low power consumption allows ZIGBEE to work for several years even when using batteries. In this way, the 3D printing factory can directly add a new printer, and the ZIGBEE network can automatically find the best path to connect the new printer; the ZIGBEE network will also be automatically repair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com