Component mounting method

An installation method and component technology, which is applied in the direction of electrical components, electrical components, electric solid devices, etc., can solve the problems of control processing control load increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

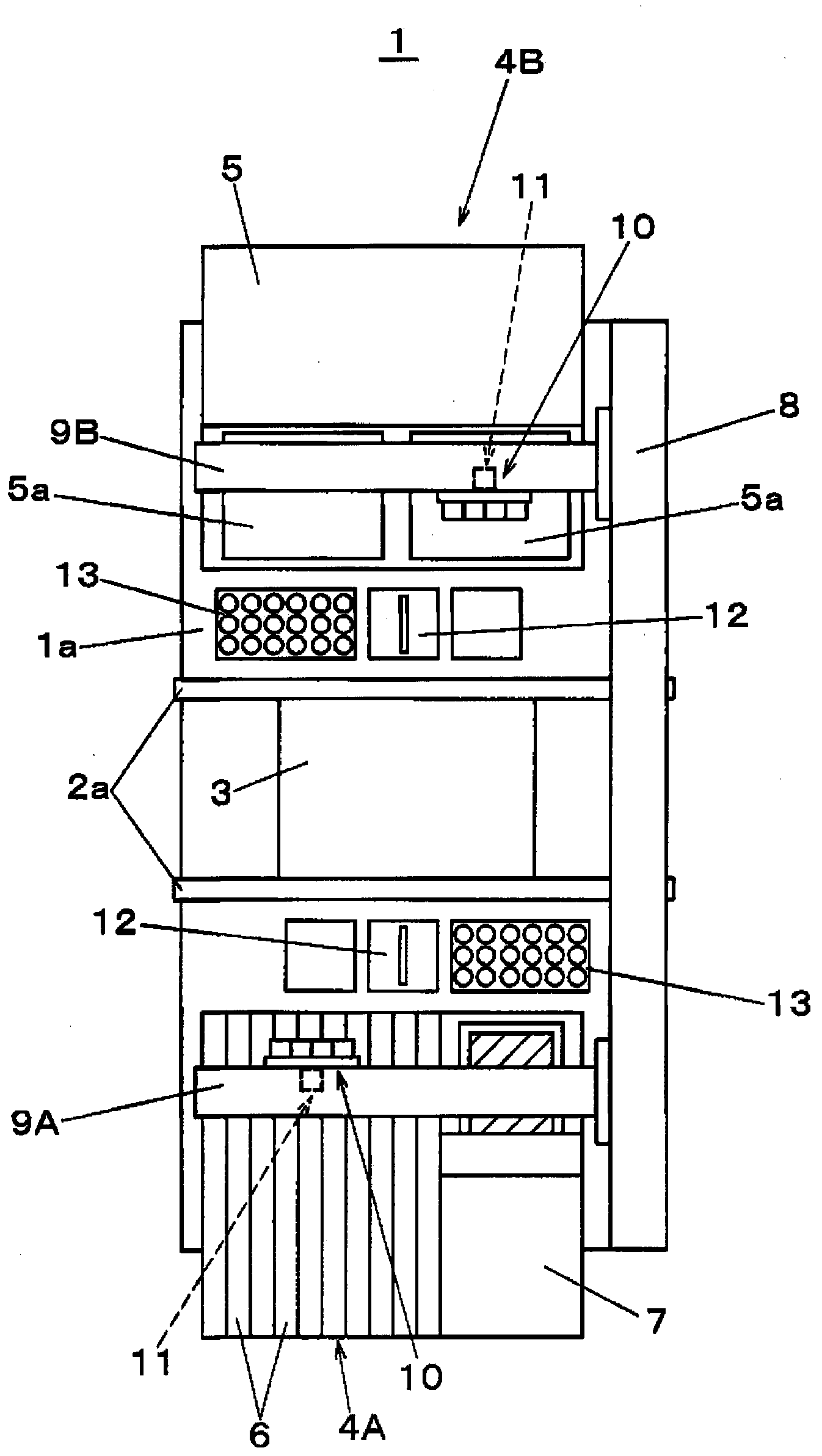

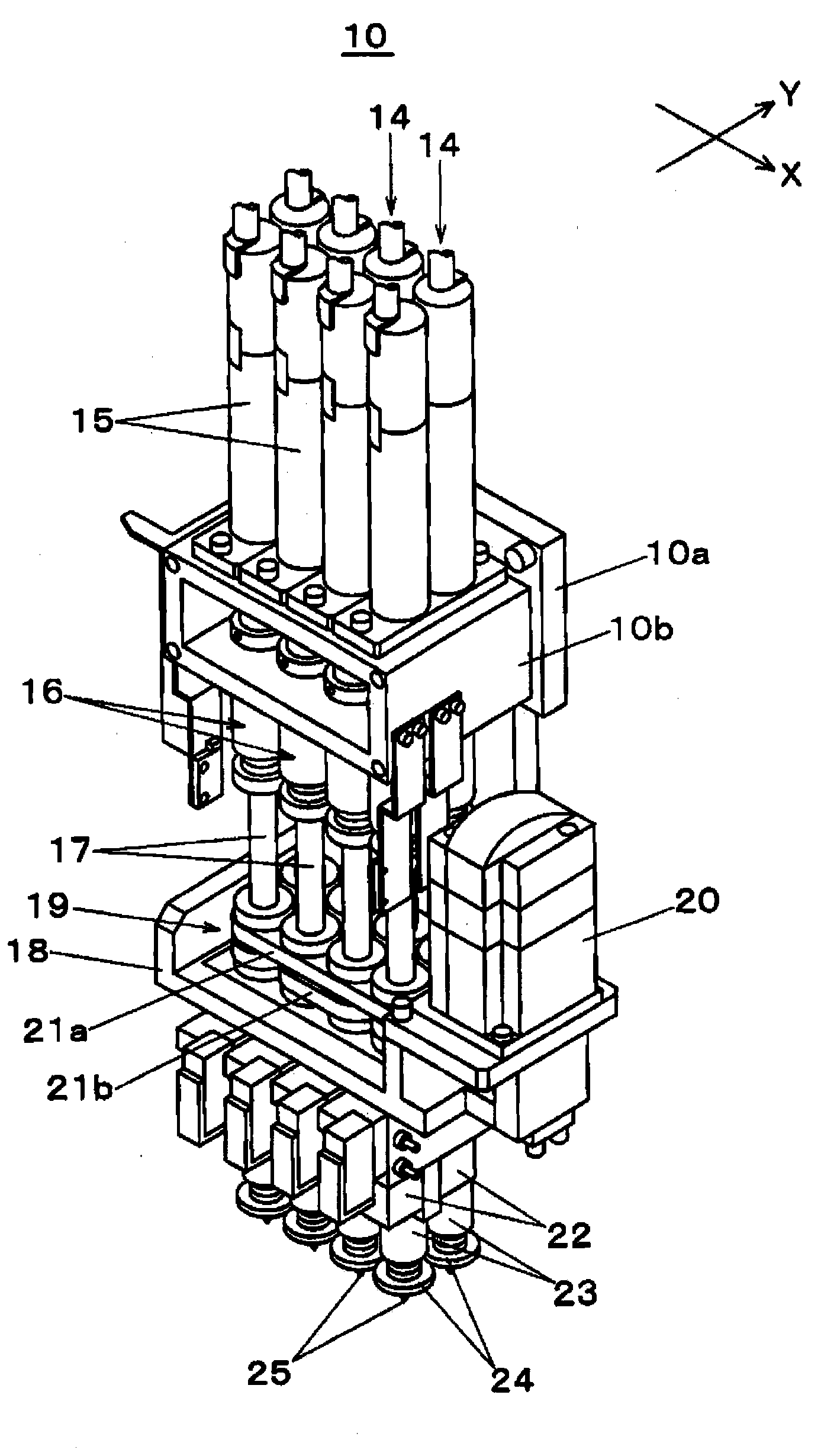

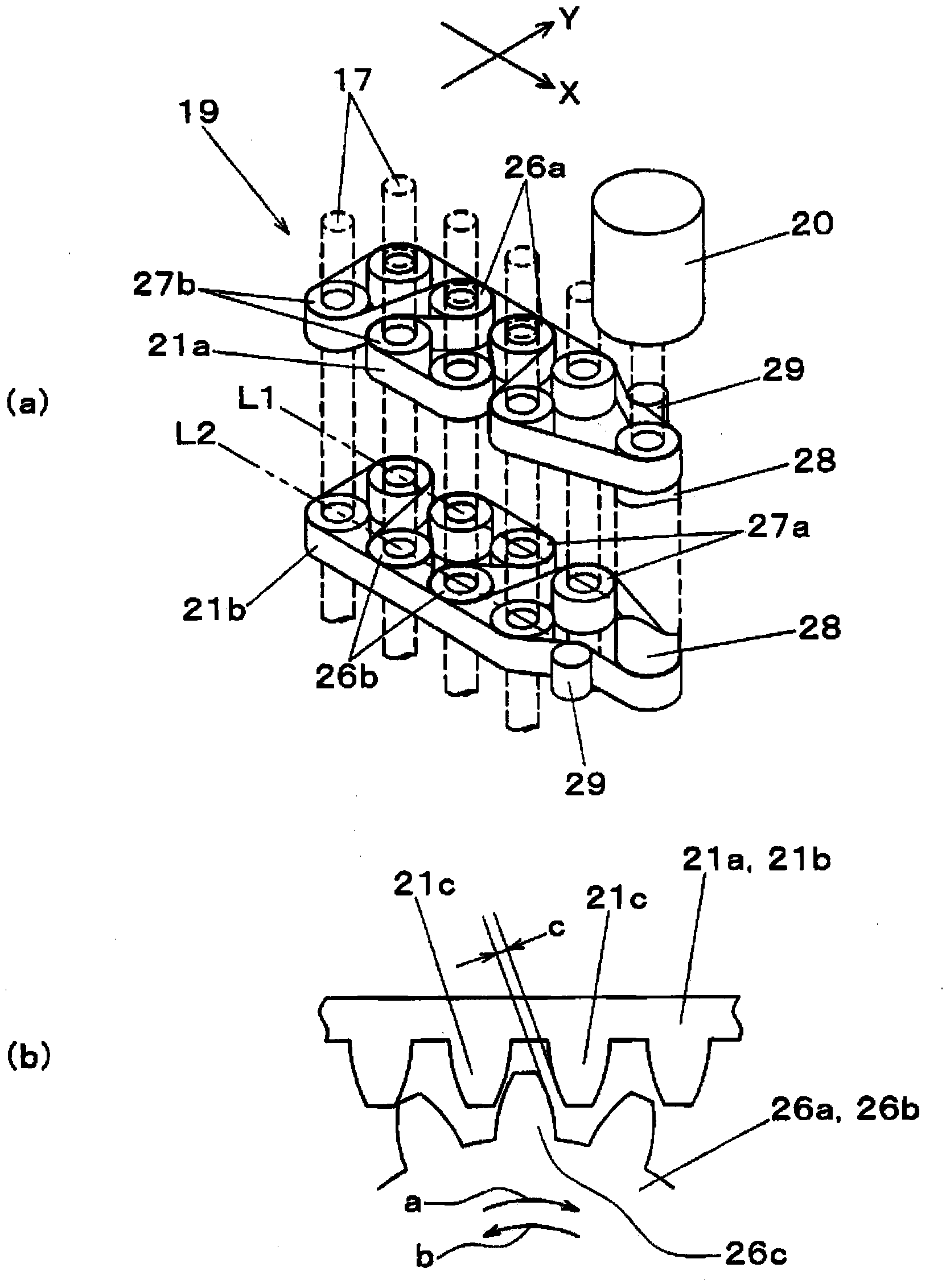

[0030] Next, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 , figure 2 The structure of the electronic component mounting device will be described. exist figure 1 Among them, on the base 1 a of the electronic component mounting apparatus 1 , the substrate conveyance mechanism 2 is arranged along the X direction (substrate conveyance direction). The substrate conveyance mechanism 2 conveys the substrate 3 to be the object of component mounting work. Component supply parts for supplying electronic components are arranged on both sides of the substrate conveying mechanism 2, and on the component supply part 4A on one side, a plurality of tape feeders 6 for supplying electronic components held on a tape and for passing through Transfer Paste transfer unit 7 for transferring paste such as solder to electronic components is detachably mounted in parallel with tape feeder 6 . The other component supply part 4B is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com