Hydraulic automatic tensioner

一种张紧器、自动的技术,应用在传动装置、皮带/链条/齿轮、机械设备等方向,能够解决制造成本高、加工困难、液压阻尼不良等问题,达到可靠性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

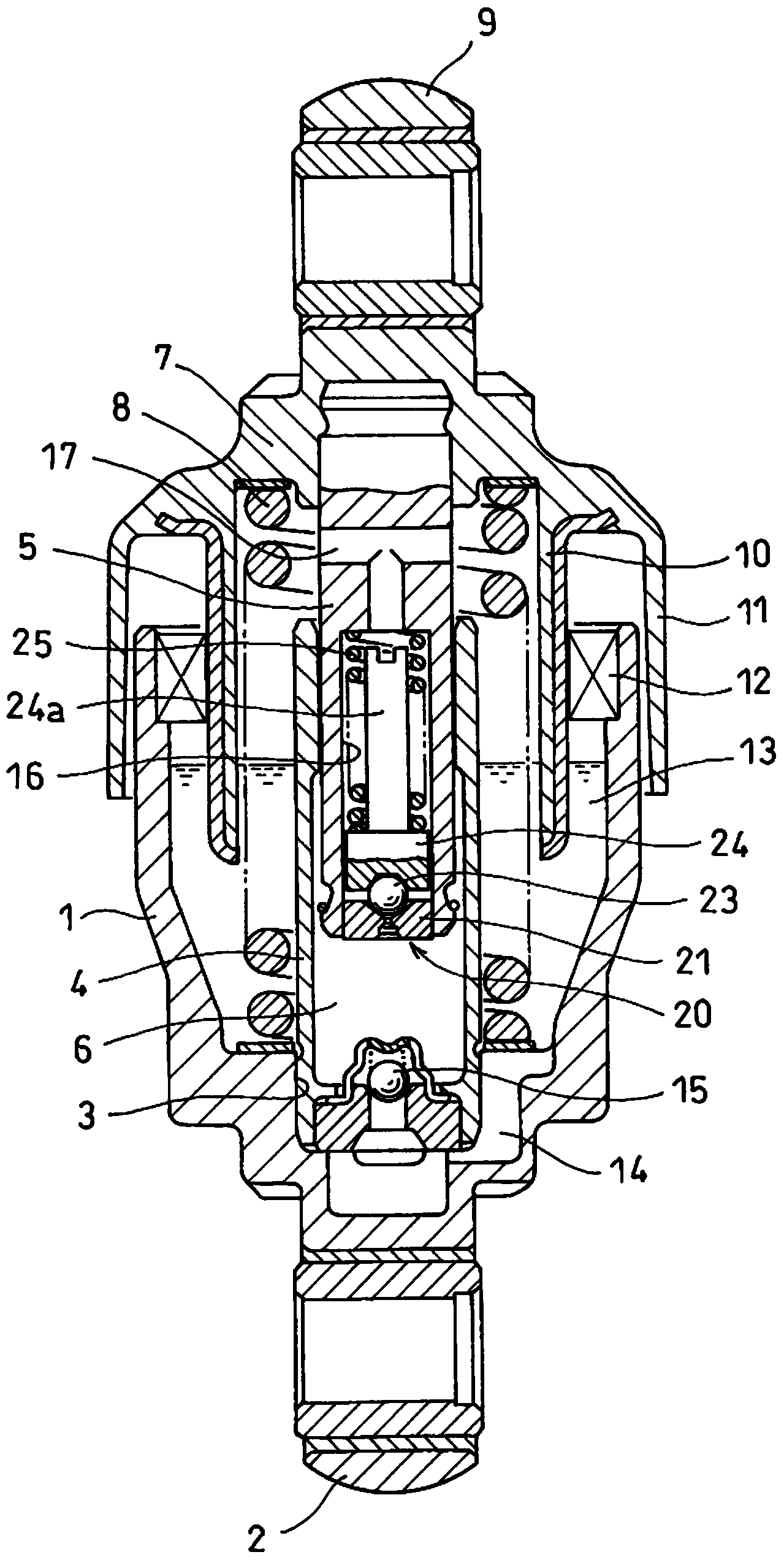

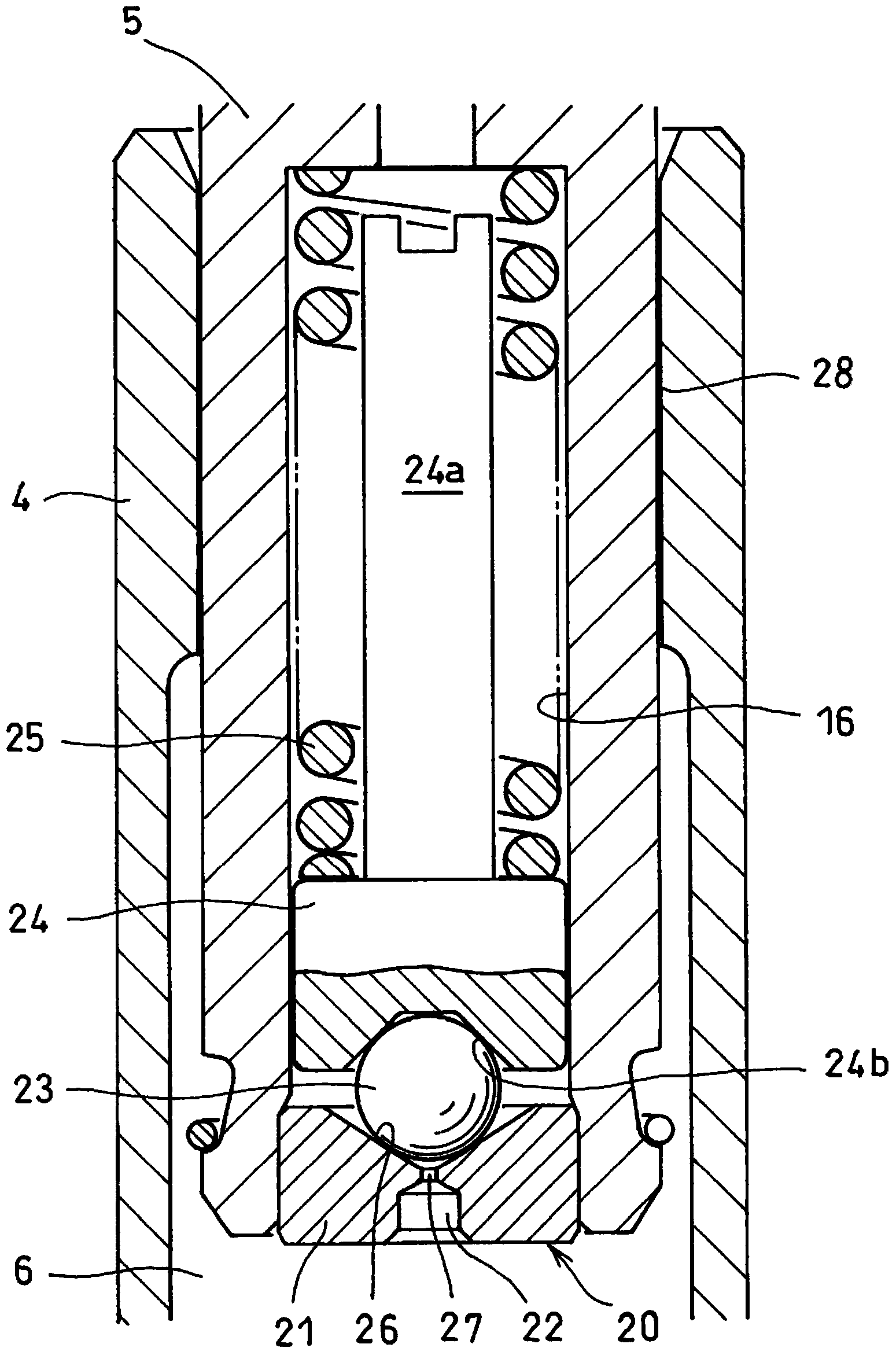

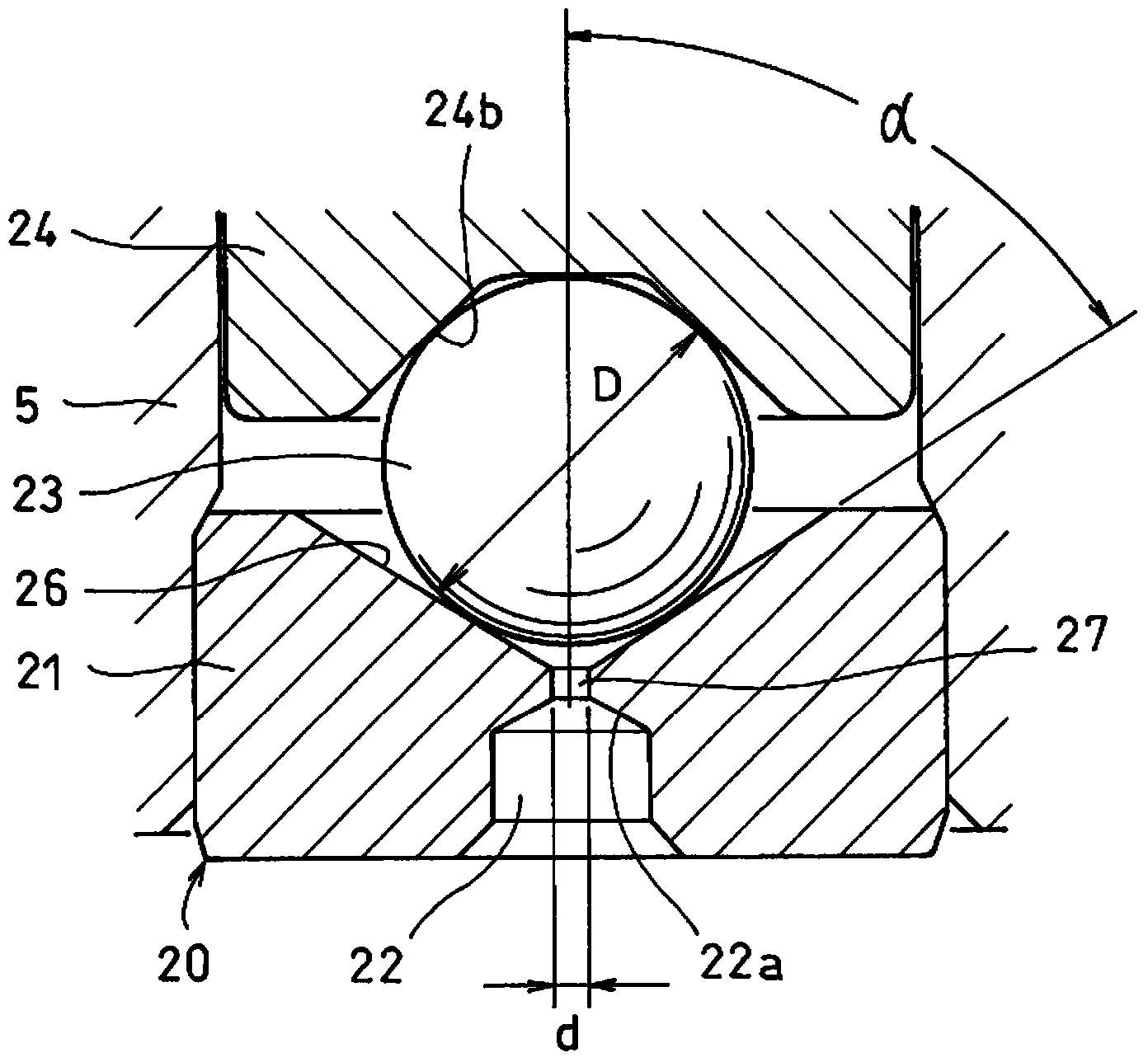

[0048] Embodiments of the present invention will be described below with reference to the drawings. Such as figure 1 As shown, the lower part of the cylinder block 1 is closed, and a connecting piece 2 rotatably connected to the engine block is provided at the closed end thereof.

[0049] A sleeve fitting hole 3 is provided on the bottom surface of the cylinder body 1 , and the lower end portion of the sleeve 4 is press-fitted into the sleeve fitting hole 3 . The lower portion of the rod 5 is slidably inserted into the sleeve 4 , and a pressure chamber 6 is provided in the sleeve 4 by the insertion of the rod 5 .

[0050] Be positioned at the outer upper end of cylinder body 1 at rod 5, be fixed with spring seat 7, the back-moving spring 8 that packs between this spring seat 7 and the bottom surface of cylinder body 1 is opposite cylinder body 1 and rod 5 to the direction of relative elongation. Apply force.

[0051] On the upper end of the spring seat 7, there is a Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com