Construction of pipes

A structure and tube technology, applied in the field of slender hollow structures, can solve problems such as unfavorable manufacturing, and achieve the effect of improving the immersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

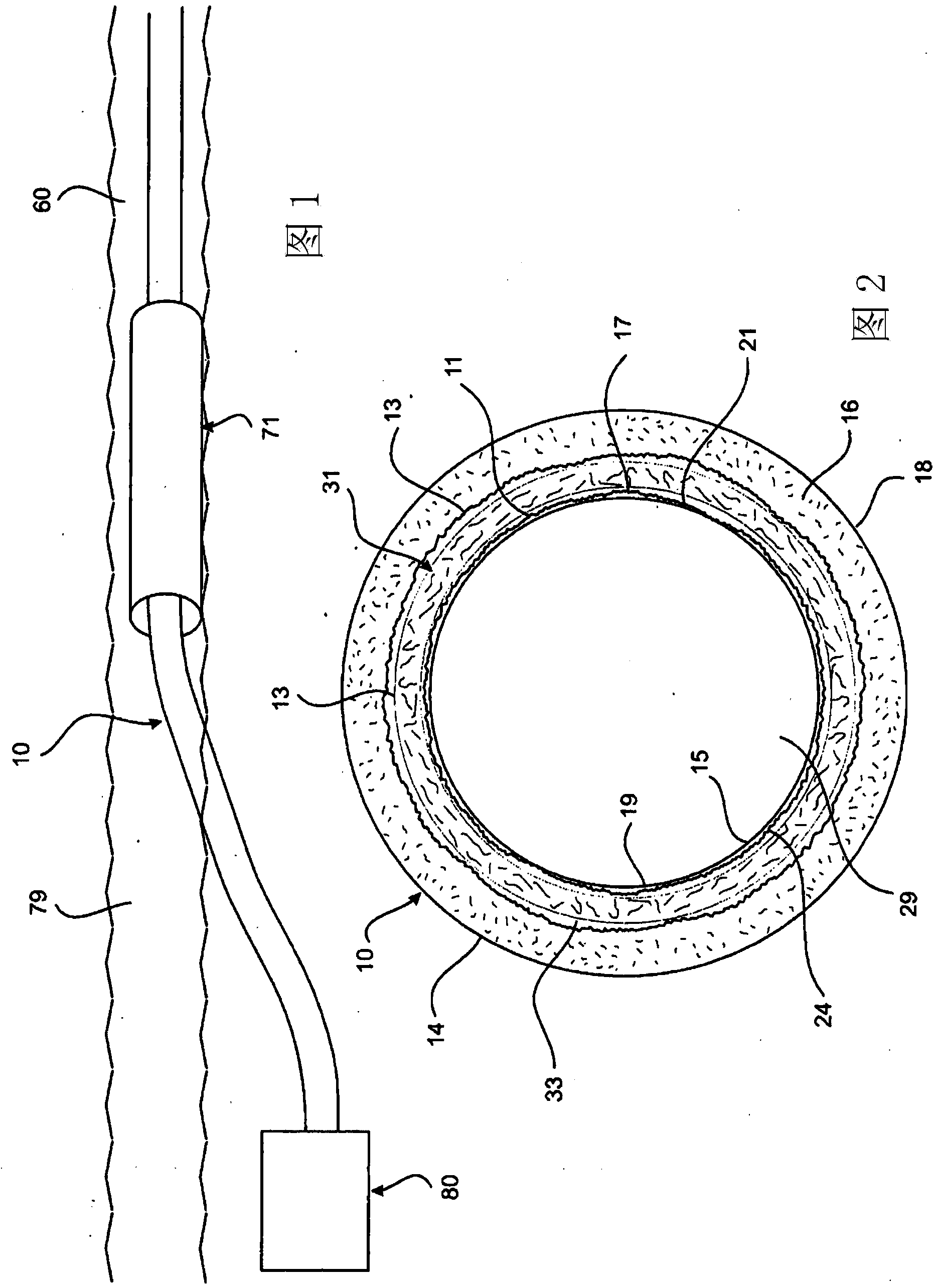

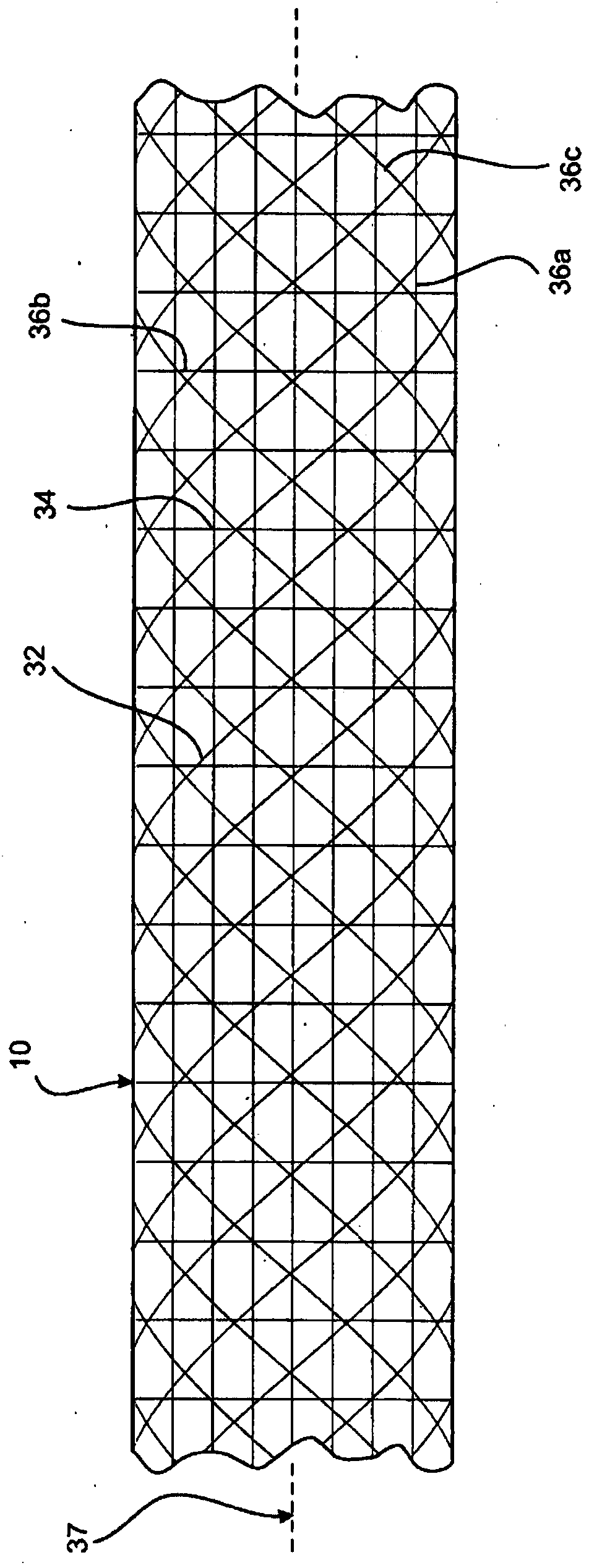

[0122] see Figure 1-22 A first embodiment of the present invention relates to an elongated hollow structure constructed in the form of a tubular element such as pipe 10, and a method of constructing the pipe on a continuous basis.

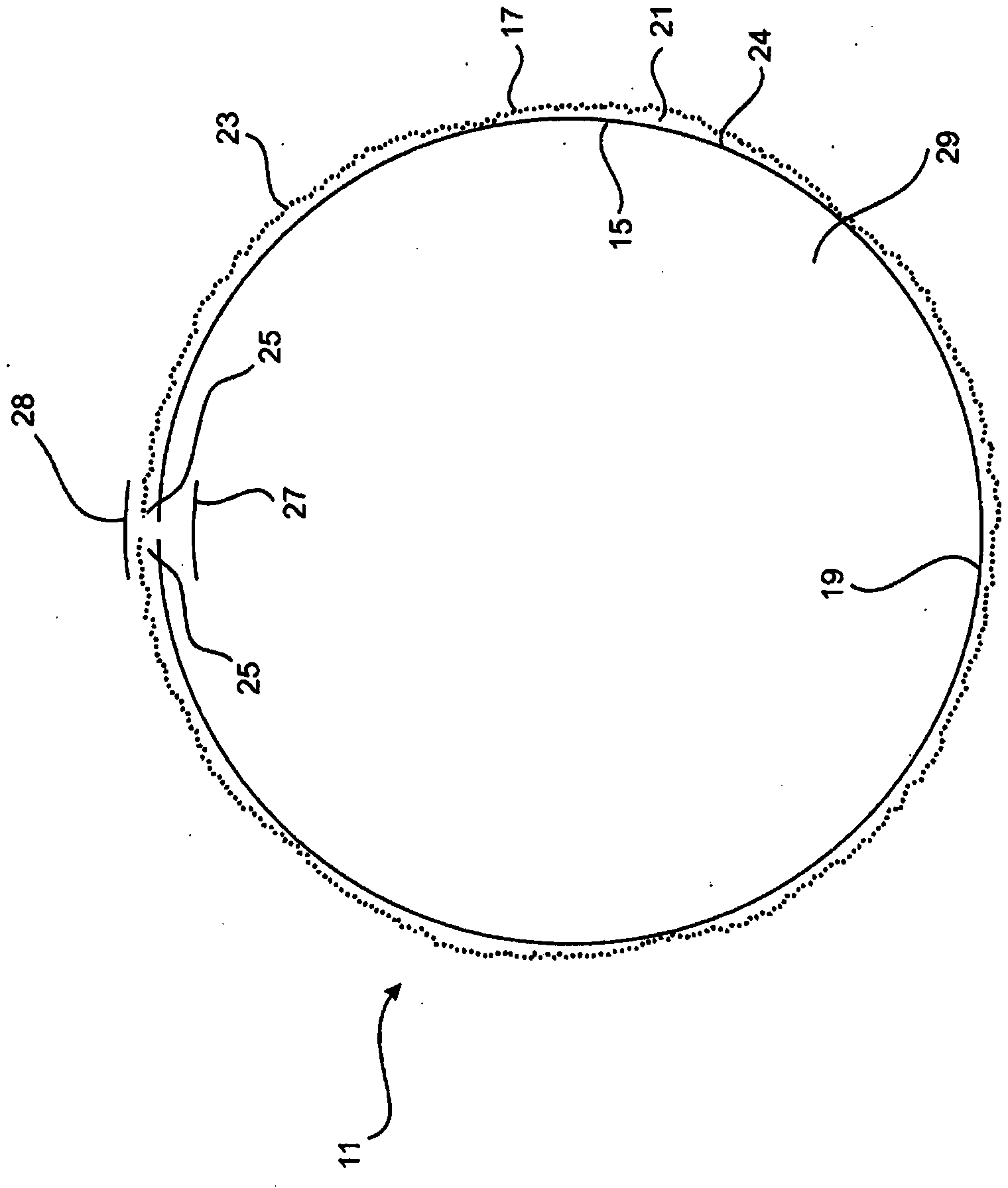

[0123] The tube 10 is of composite construction, comprising a radially inner portion 11 and a radially outer portion 13, the two parts 11 and 13 merging together to provide a complete tube wall structure. In said structure, the exterior 13 is enclosed in a protective sheath 14 comprising a hardenable component 16 such as glue or concrete comprised of an outermost layer 18 which may be of any suitable material, Such as geotextiles. The protective sheath 14 serves to provide protection to the pipe 10 against compressive loads to which the pipe may be subjected once installed.

[0124] The interior 11 comprises an inner liner 15 to which a layer 17 of resin absorbent material is bonded to one face. The other face of the inner sleeve 15 defines an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com