Self-discharge sorting process for lithium iron phosphate batteries

A lithium iron phosphate battery and battery discharge technology, which is applied in the field of lithium-ion batteries, can solve the problems of easy mismeasurement, large labor cost, and high equipment investment, and achieve high sorting accuracy, easy popularization and application, and low battery sorting costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

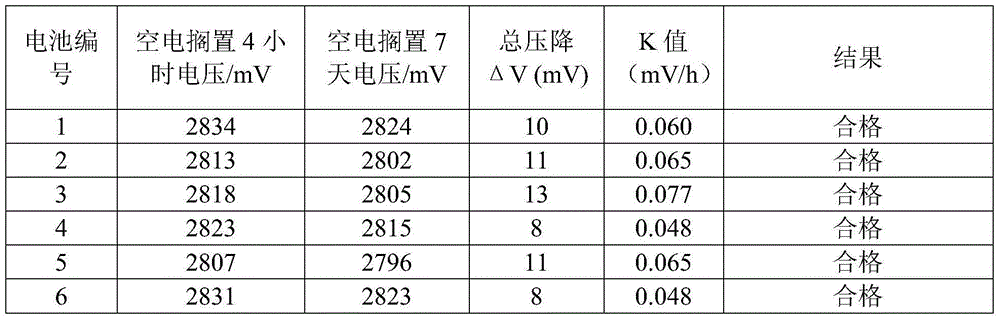

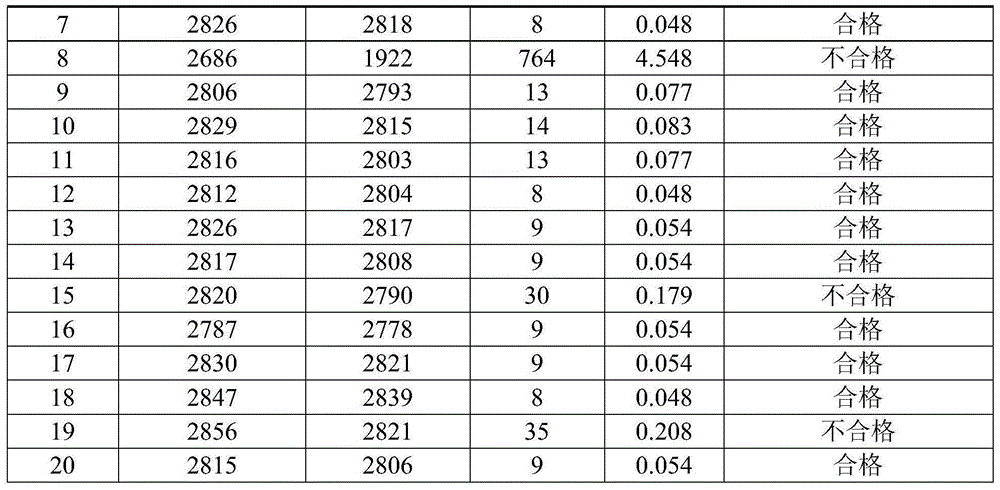

[0015] A self-discharge sorting process for lithium iron phosphate batteries, comprising the following steps in sequence:

[0016] A. Discharge the 20-cell 18650-type lithium iron phosphate battery 1C to 2.0V, and leave it for 5 minutes.

[0017] 0.05C discharge to 2.0V;

[0018] B. Leave it aside for a period of time T1 is 4 hours, record the battery open circuit voltage V1;

[0019] C. Put it aside for a period of time T2 is 7 days, record the battery open circuit voltage V2;

[0020] D. Calculate the voltage drop ΔV=V1-V2 of the battery within 7 days and the average hourly voltage drop K=(V1-V2) / (7*24) within 7 days;

[0021] E. Set the upper and lower limits of ΔV and K, and reject unqualified products that are not within the range.

[0022] The test results are shown in the table below. According to the actual use requirements of the battery, the upper and lower limits of ΔV and K are set to 5-15mV and 0.04-0.09mV / h in this embodiment, and the batteries whose ΔV and K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com