Long-distance heavy-load drag chain supporting device

A long-distance drag chain technology, applied in the field of drag chains, can solve the problems of unsuitable closed drag chains and worn drag chains, and achieve the effects of improving service life, reducing quantity, and ensuring operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

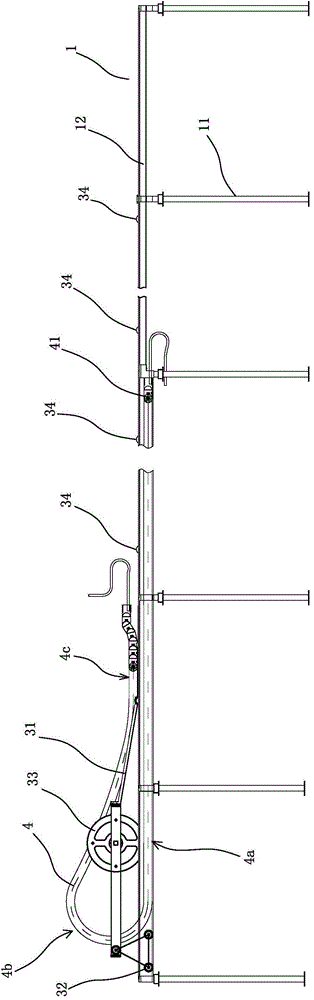

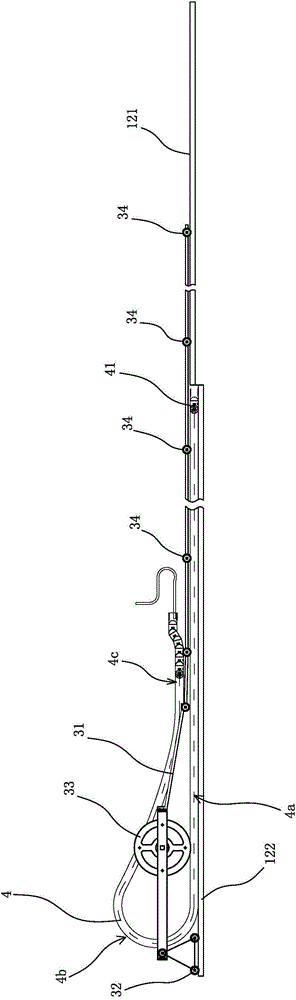

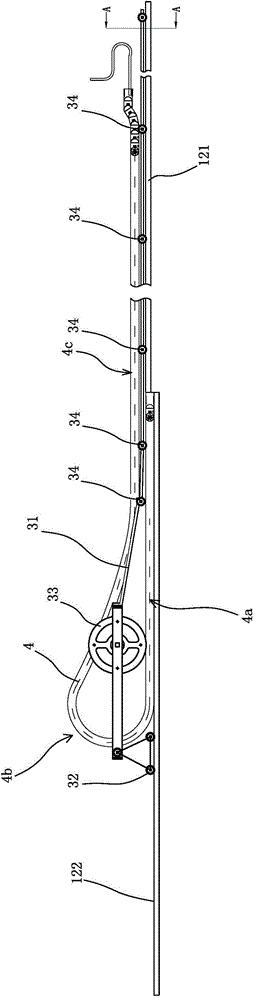

[0026] refer to Figure 1 to Figure 7 As shown, a long-distance heavy-duty drag chain supporting device includes a supporting frame 1 and a supporting mechanism.

[0027] The support frame 1 is provided with two first guide rails 122 extending horizontally and two second guide rails 121 extending horizontally. The first guide rails 122 extend from one end of the support frame 1 to the fixed end 41 of the drag chain 4. The second guide rails 121 extends from the fixed end 41 of the drag chain 4 to the other end of the support frame 1. The specific support frame 1 is composed of several support feet arranged at intervals in the transverse direction and two guard plates 12 bridged between two adjacent support legs. The plate 12 extends horizontally along the transverse direction and is arranged symmetrically. A guide groove for accommodating the drag chain 4 is formed between the two guard plates 12 . Both ends are fixed on the support beam 13, the guard plate 12 is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com