Mixed use control method of large and small yarn bobbins

A control method and yarn bobbin technology, applied in the field of textile manufacturing, can solve problems such as waste of raw materials, and achieve the effect of reducing production difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Two yarn bobbins of different sizes on the same warping machine, the tension is set at 1N, the measured line speed is 400m / min, and the rotation speed of the large yarn bobbin is 780r / min, and the actual rotational diameter of the yarn bobbin is calculated to be 0.1633 m, the output torque of the motor is 0.0816N·m, and the rotation speed of the small bobbin is 800r / min. The actual rotational diameter of the bobbin is calculated to be 0.1592m, and the output torque of the motor is 0.0796N·m.

Embodiment 2

[0019] Example 2: For a single yarn bobbin, set the tension to 2N, measure the linear velocity to 300m / min, and the yarn bobbin rotation speed is 800r / min at the beginning, calculate the actual rotational diameter of the yarn bobbin to be 0.1194m, and the output torque of the motor to be 0.1194N m, after the warping machine has been running for a period of time, the measured rotation speed of the yarn bobbin is 900r / min, the calculated actual rotational diameter of the yarn bobbin is 0.1061m, and the output torque of the motor is 0.1061N·m.

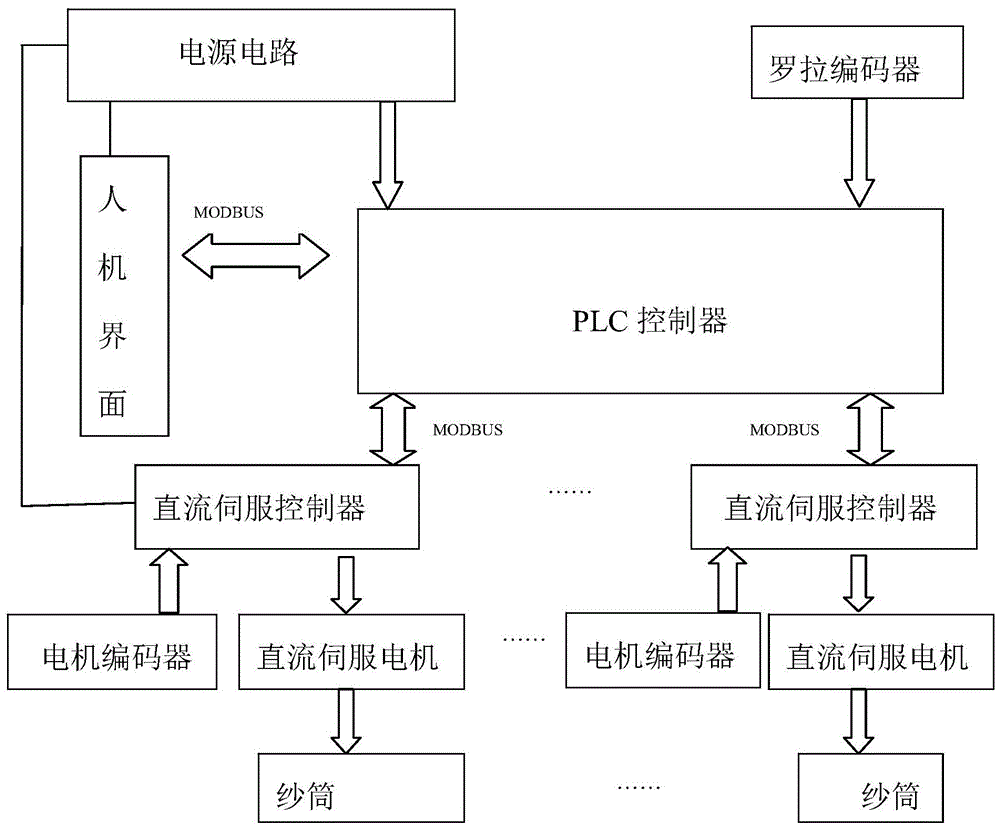

[0020] In the present invention, one DC servo controller corresponds to controlling one DC servo motor, one DC servo motor corresponds to controlling one yarn bobbin, all DC servo controllers and one PLC controller transmit signals, and the output of each servo motor is obtained through signal transmission and calculation Torque, to ensure the same yarn tension of the yarn tubes with different diameters, and also to ensure that the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com