Warp knitting machine and method for operator assistance in a warp knitting machine

A warp knitting machine and warp beam technology, applied in the field of warp knitting machines, can solve time-consuming and cumbersome problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

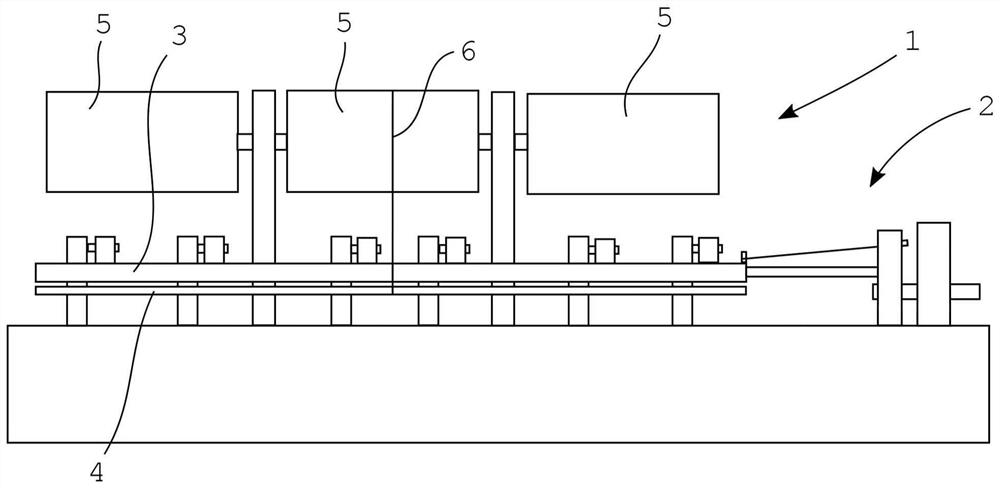

[0050] figure 1 A schematic diagram of a warp knitting machine 1 with a tensioned spring tension system 2 according to the invention is shown. The warp knitting machine 1 has a guide bar 3 and a needle bar 4 . Warp yarns 6 are loaded on a plurality of warp beams 5 of the warp knitting machine 1, wherein figure 1Only one warp thread 6 is shown by way of example. The warp yarn 6 is guided from the warp beam 5 to the guide bar 3 . Beneath the guide bar 3 , the warp threads 6 are hooked by the not shown knitting needles of the needle bar 4 during the knitting process and knitted into a cloth.

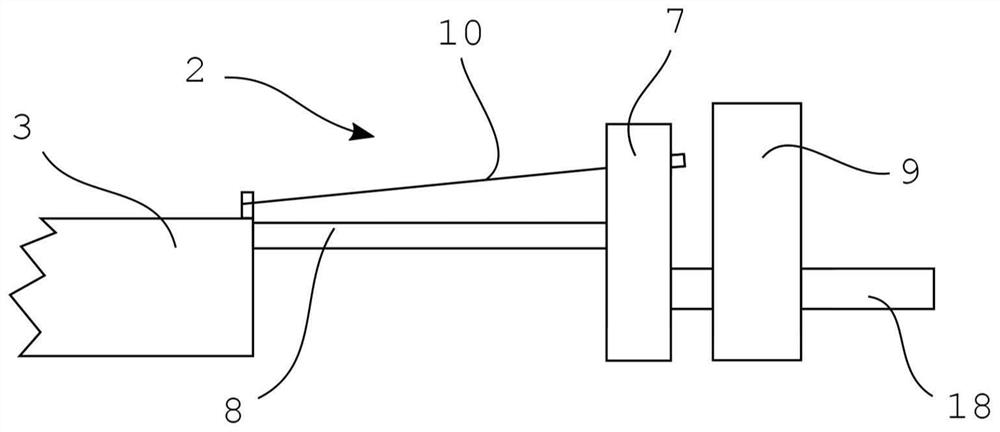

[0051] figure 2 A schematic diagram of the spring tension system 2 of the warp knitting machine 1 with the pusher 7 , the push rod 8 and the stop 9 is shown. exist figure 2 The thread guide bar 3 , which is only partially shown in FIG. 2 , must be moved along its longitudinal axis during the knitting process. This movement is brought about by a not shown drive of the warp knitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com