Miniature excavator rotation frame

A technology of excavator and slewing frame, which is applied in the field of miniature excavator slewing frame, which can solve the problems of small thickness of peripheral parts, difficult production cycle, and large thickness of core parts, and achieve small error, easy calibration and correction, and convenient production and installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

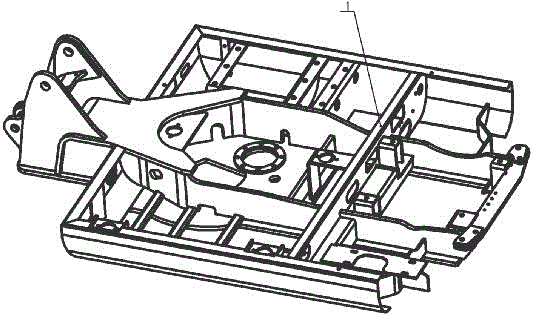

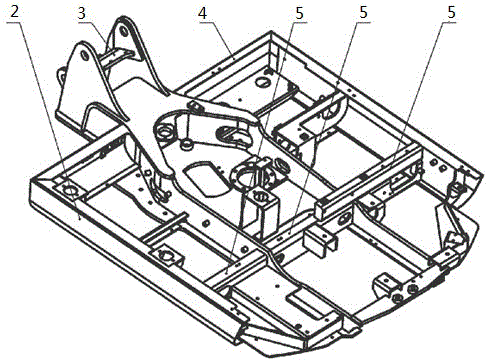

Image

Examples

Embodiment 1

[0013] Embodiment 1, with reference to Figure 1 ~ Figure 2 , the main structure of the frame is composed of the left frame (2), the right frame (4), and the top frame (3), and the middle beam is composed of three left, middle and right sections. Left frame (2), right frame (4), top frame (3) are integrated respectively, make with angle steel, horizontal steel, sheet steel material. Connection between the left frame (2), the right frame (4), and the top frame (3) is with snap-fit type, with embedded, and with welded type all achieves purpose equally. In the process of fixing and positioning, the error and deformation of component welding can be corrected and eliminated. There are fewer weld seams in the process of welding the three major components, and the strength of the components is good. This structural welding reduces the weld seam in the final welding link, and the process of combining the three major components is a process of repositioning and correction. ...

Embodiment 2

[0014] Embodiment 2, a mini-excavator slewing frame, including prior art structure, left frame, top frame, right frame, crossbeam, characterized in that the upper part between the left frame (2) and the left frame (2) is the top frame (3), the beam (5) is in the middle, the top frame (3) protrudes upwards, the beam (5) is divided into left, middle and right three-section connection, the left frame (2), the top frame (3), and the right frame (4) Embedded connection is used for connection, and welding connection is also available, and the crossbeam (5) between the left frame (2) and the right frame (4) is connected with embedded. A dividing plate is arranged between the left frame (2), the right frame (4) and the top frame (3). The crossbeams (5) on the left, middle and right are integrated into one body with snap-in type, and / or embedded, and / or welding type. Left frame (2), right frame (4), top frame (3), crossbeam (5) are made with angle steel, horizontal steel, sheet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com