Patents

Literature

47results about How to "Calibration is easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

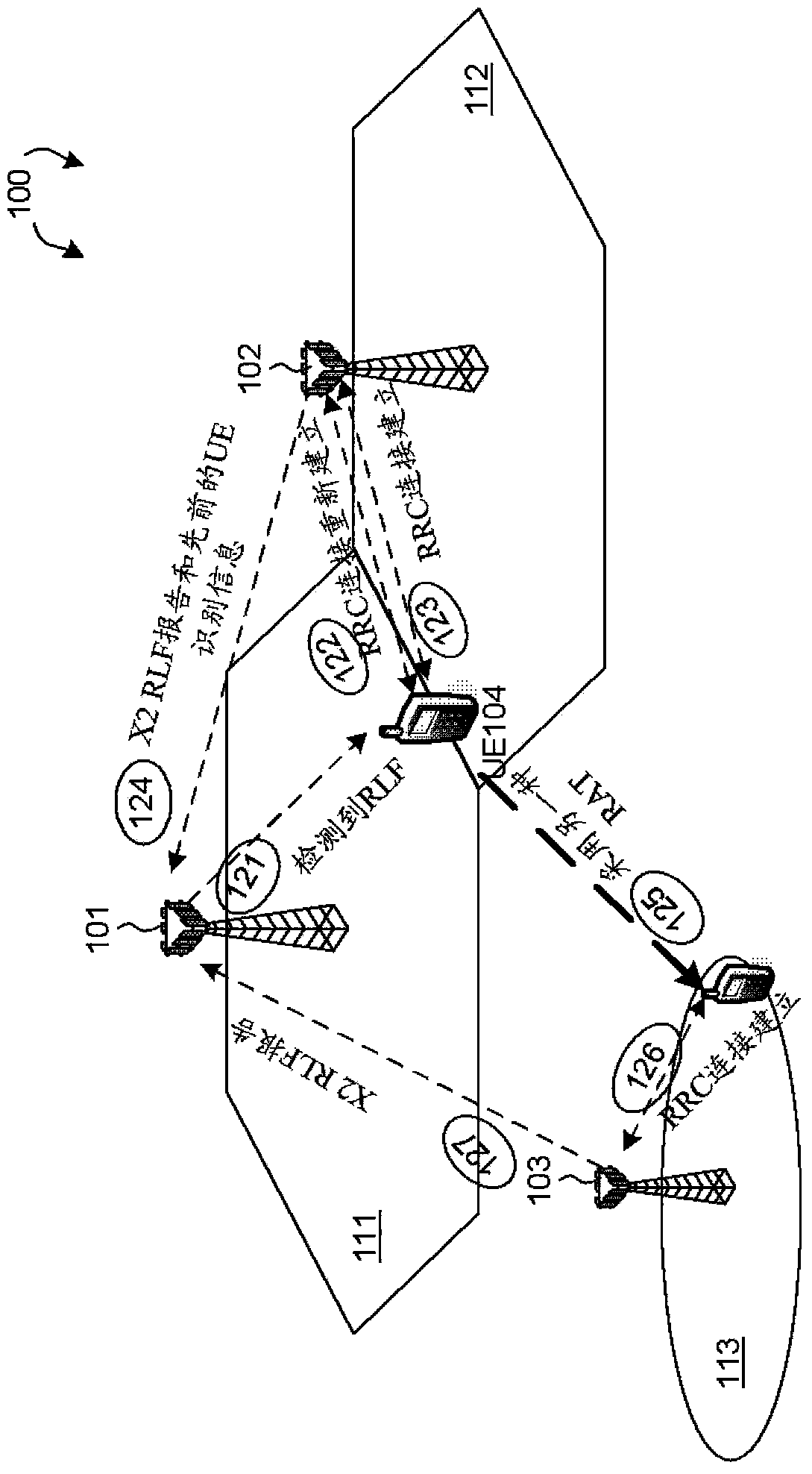

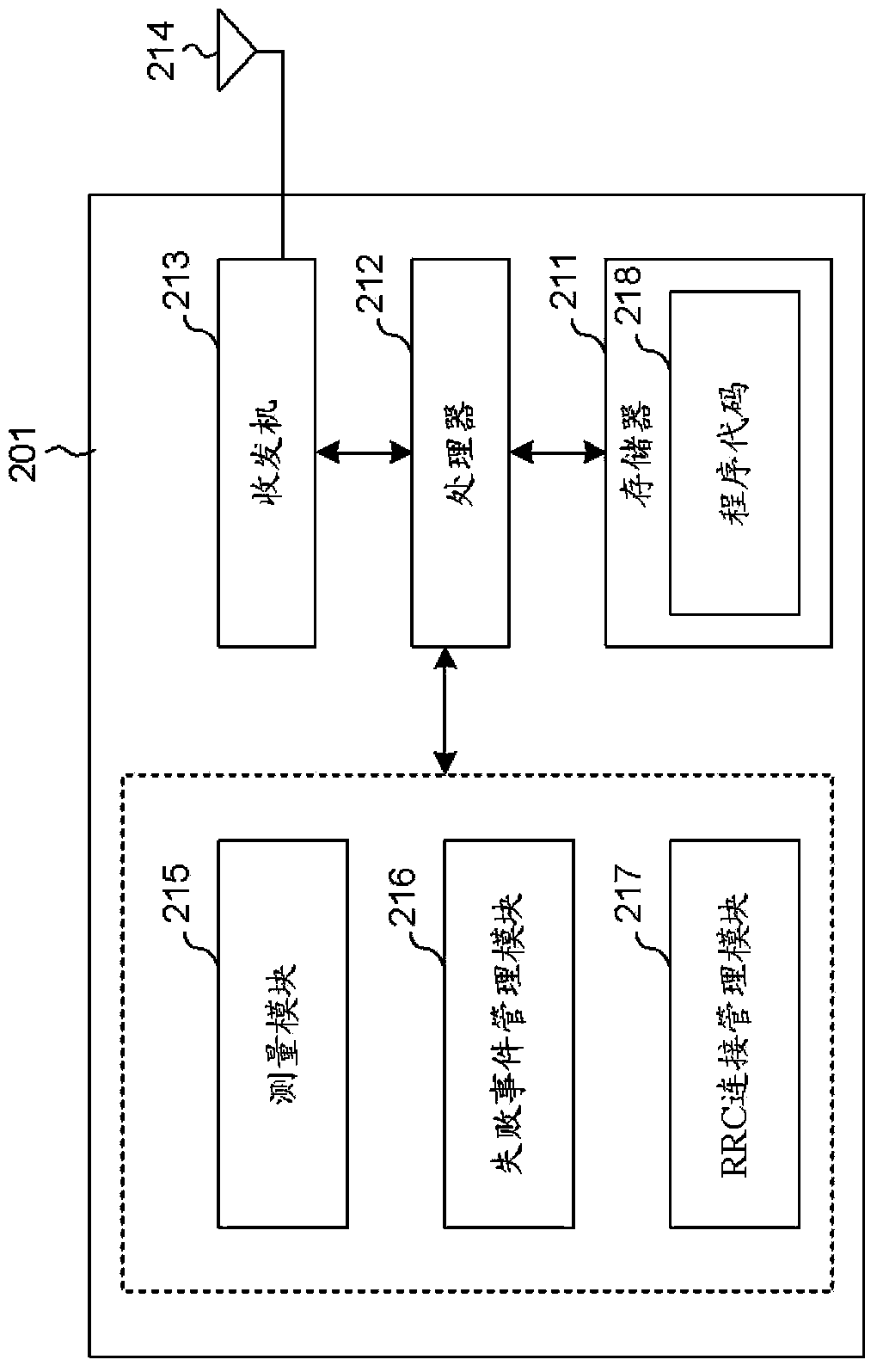

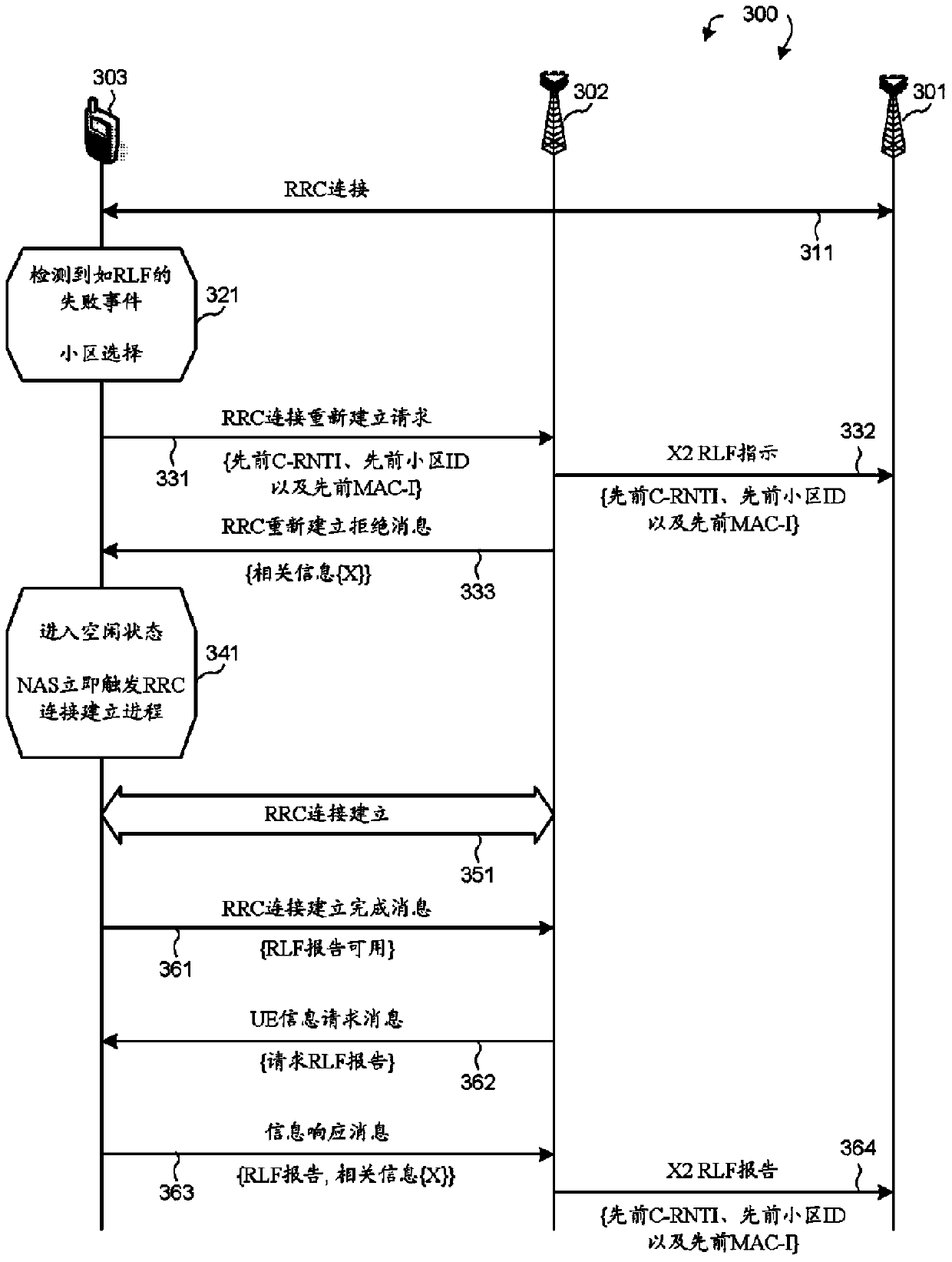

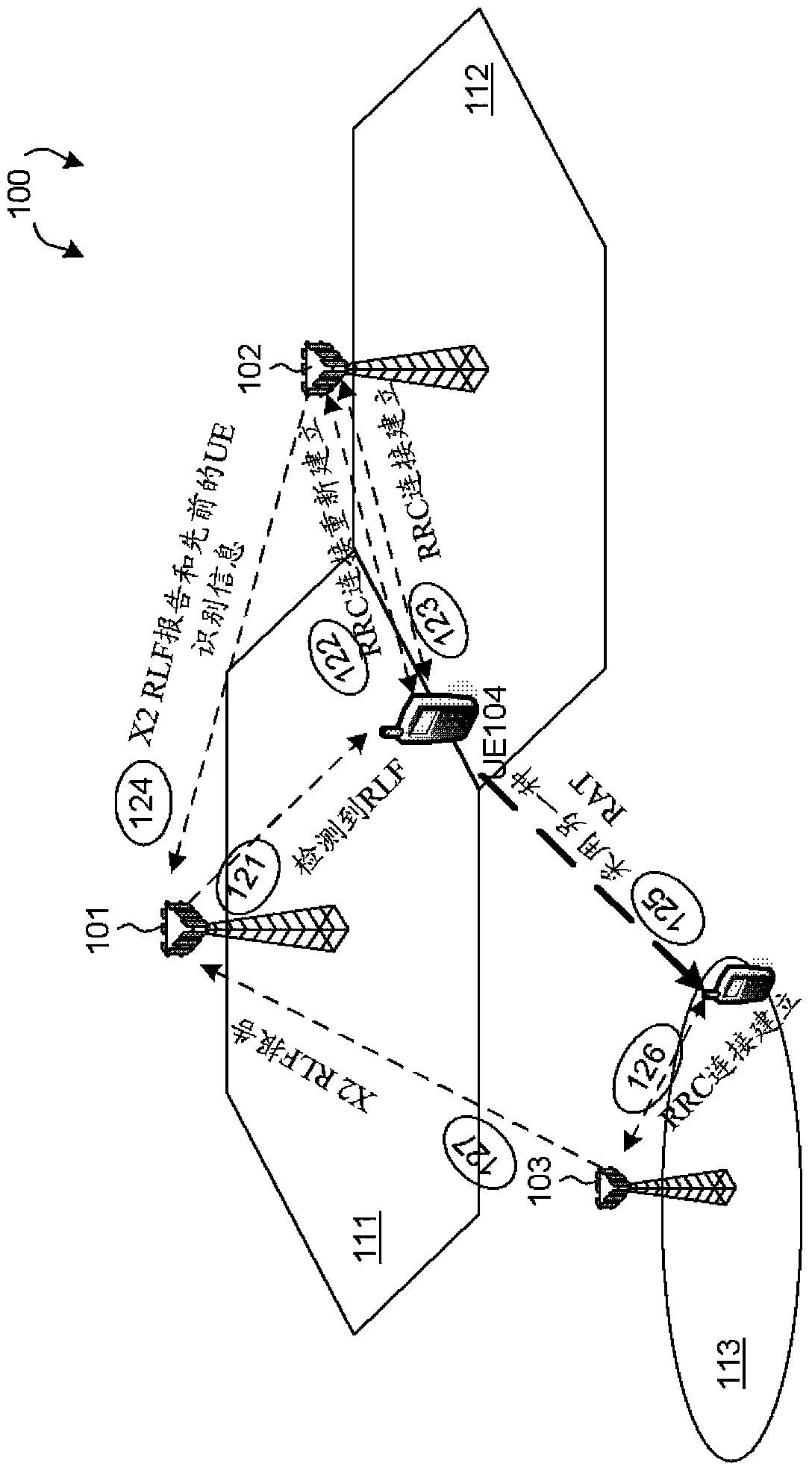

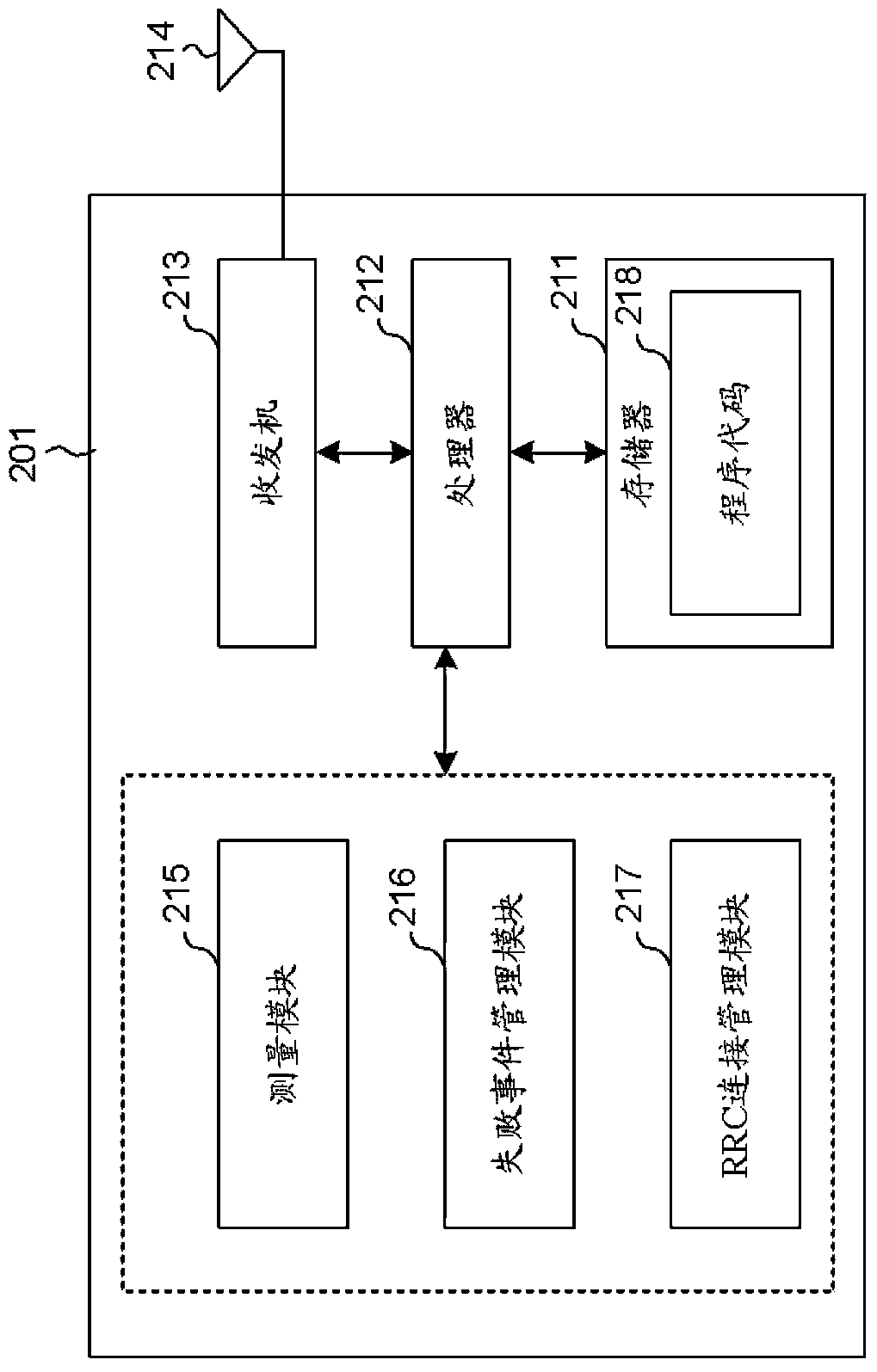

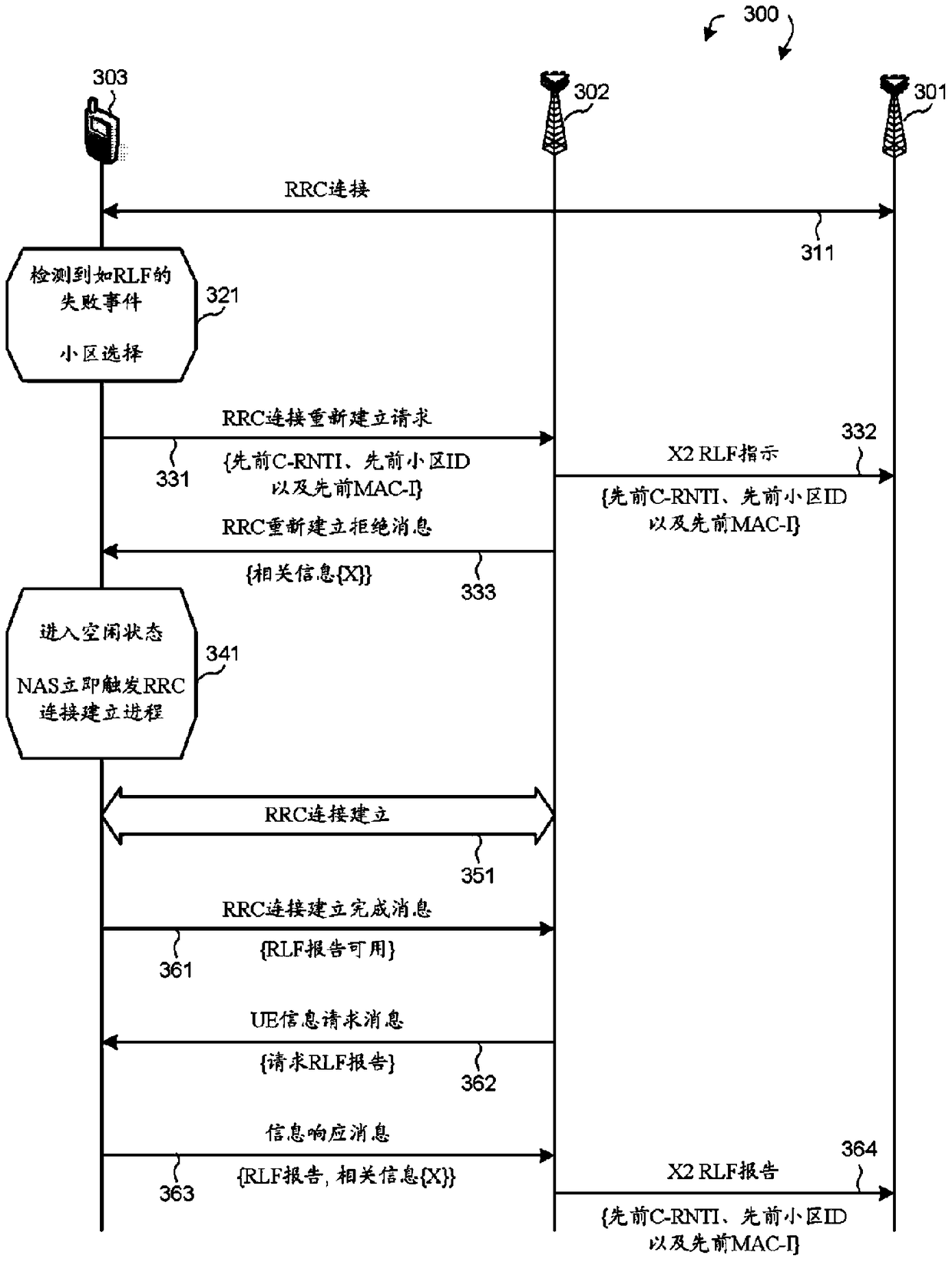

Method of reporting connection setup failure and user equipment

The invention provides a method of reporting connection setup failure and user equipment. The method of reporting connection establishment failure comprises the steps: in a wireless communication network, the user equipment is connected to a cell served by a base station from a wireless resource control idle state; when the wireless resource control connection setup is tried and the base station carries out a random access channel course, the wireless resource control connection setup is failed, and the user equipment records failure event reporting when the random access channel course is failed; and in a wireless resource control connection state, the failure event reporting is sent to the wireless communication network, and the failure event reporting comprises information related to the wireless resource control connection setup trying. Through the method of reporting connection setup failure and the user equipment, the network can be better rectified.

Owner:HFI INNOVATION INC

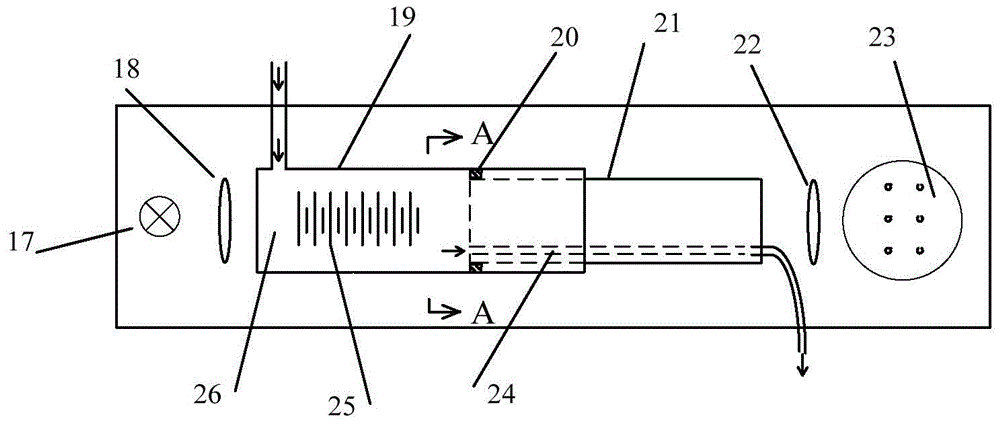

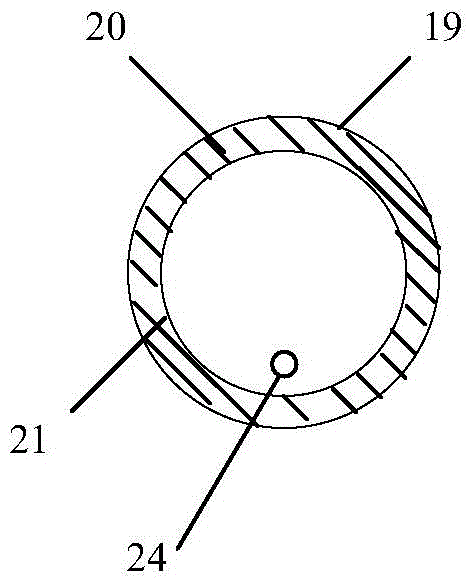

Traceable calibration method and calibration device for dynamic characteristic of big pressure sensor

InactiveCN101358894AEffective protectionWide frequency band coverageFluid pressure measurementForce/torque/work measurement apparatus calibration/testingUltra short pulseTransducer

The invention relates to a method of the dynamic characteristic traceability calibration of a high-pressure transducer, and calibration equipment, belonging to the technical field of pressure transducer. The method is as follows: exerting a static pressure on a high-pressure transducer to be calibrated, for realizing a frequency area to be zero frequency traceability calibration; on the basis, exerting an ultra-short pulse motivating pressure, testing the frequency responding characteristic of the high-pressure transducer through a test or a metrologic instrument. The method has the advantages that the method uses a common hydraulic pressure calibration method to realize the dynamic characteristic traceability calibration of the high-pressure transducer; because of adopting a pre-exerting static pressure processing method, the reversed pressure received by the transducer to be tested is reduced, thus effectively protecting the expensive transducer, and the frequency service range of the calibration method is 0-1MHz; the pressure value is as high as 800MPa, the calibration method is advanced, has the creative thought, is worthy of being popularized and learned; the adopted calibration equipment has simple structure, low cost, safe calibration process, no damage to the transducer, high calibration pressure value and wide frequency service range which can cover the zero frequency for traceability calibration, and the calibration equipment is worthy of being adopted and popularized.

Owner:ZHONGBEI UNIV

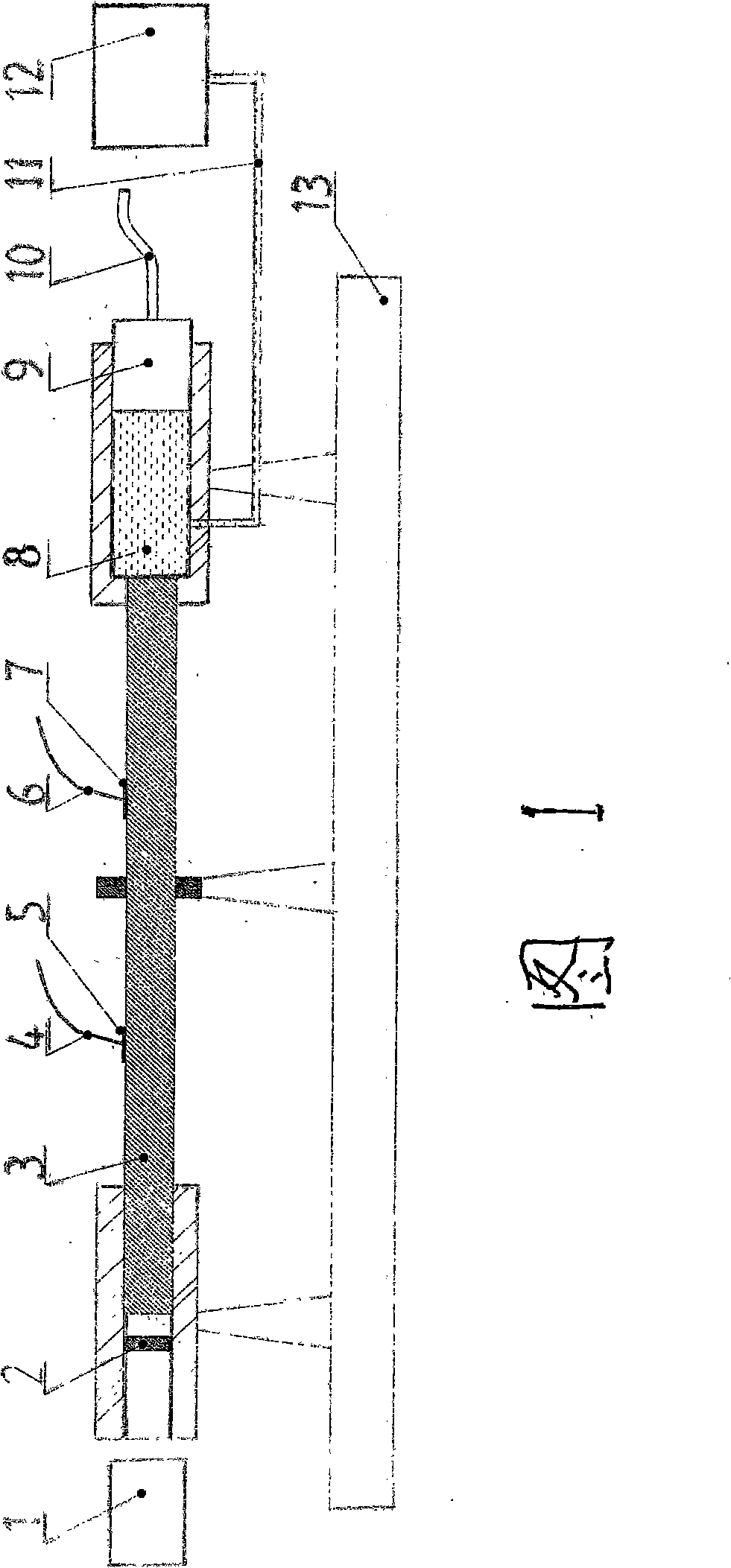

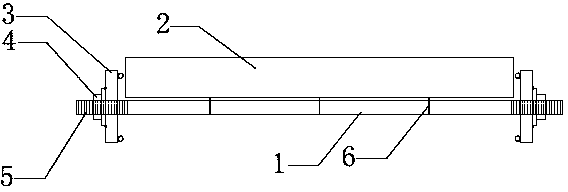

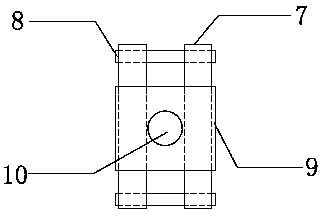

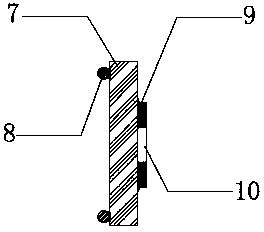

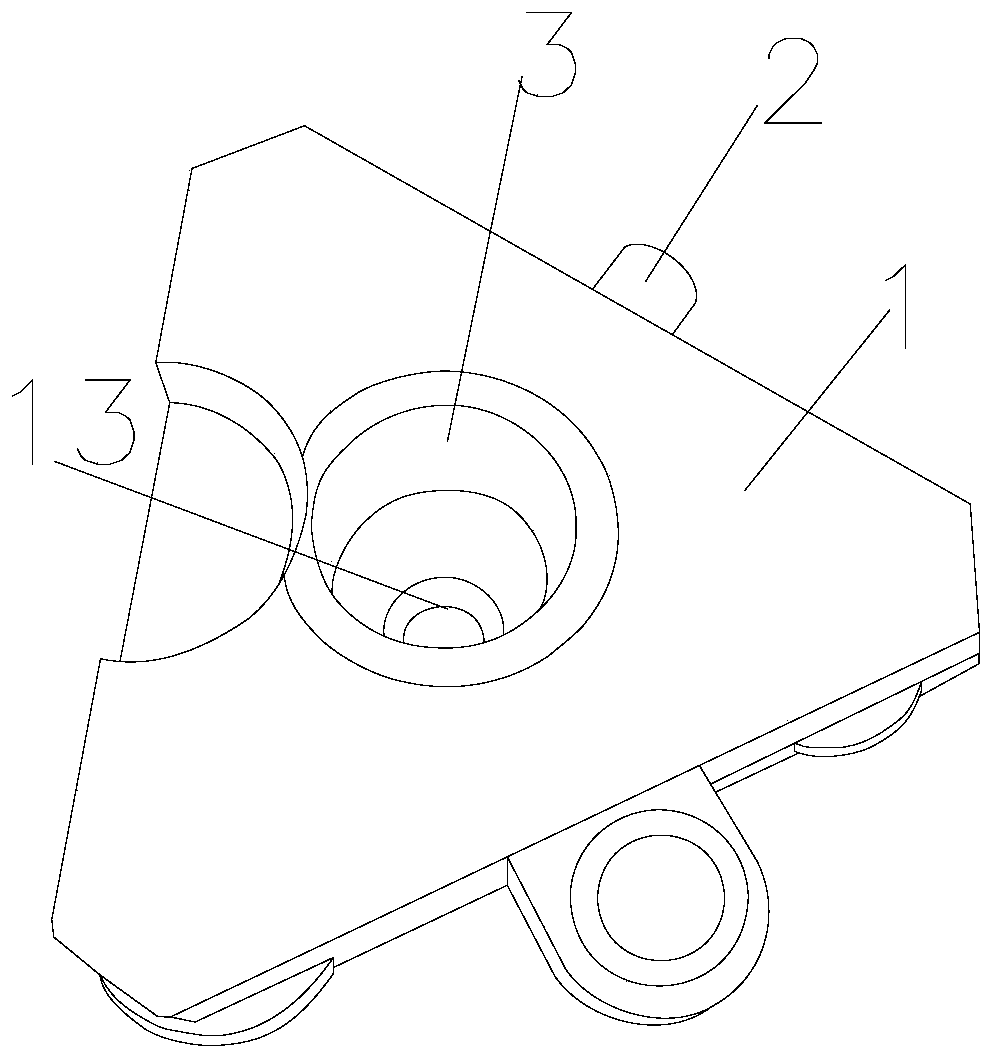

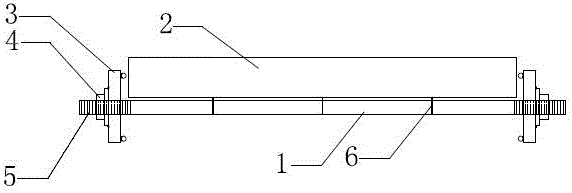

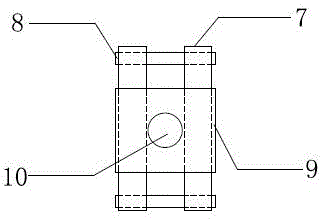

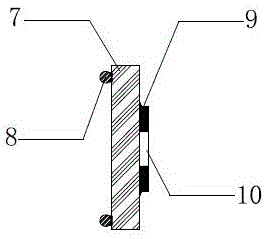

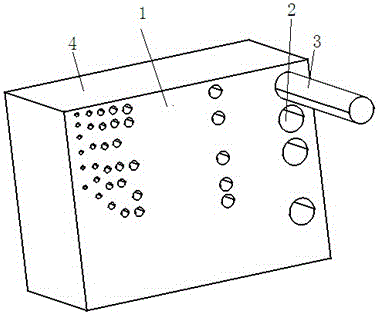

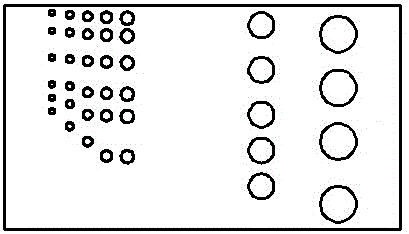

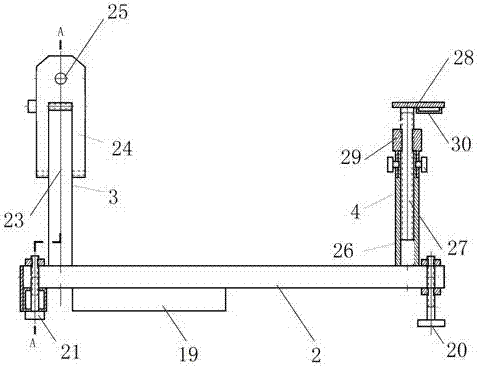

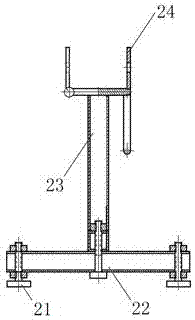

Mounting correction tool for protection corner angle of frame column and manufacturing method thereof

ActiveCN103967042ASimple structureEasy to manufactureFoundation engineeringBuilding material handlingEngineeringSmall hole

The invention relates to a mounting correction tool for a protection corner angle of a frame column. The tool comprises a screw rod (1), a square pillar (2) and two clamping pieces (3). The tool is characterized in that the screw rod (1) is a screw rod with the diameter of 12 to 16mm, the screw rod is made of round steel, the length of the screw rod is 200mm longer than that of the sectional dimension of the mounted frame column, threads which are formed in both ends of the screw rod are matched with fixing nuts (4), and a plurality of small holes for allowing iron nails (6) to pass through are drilled in the middle part; the length of the square pillar (2) is 5mm longer than that of the sectional dimension of the mounted frame column, and the small holes of the screw rod (1),through which the iron nails (6) pass, are connected and fixed with the screw rod (1); the clamping pieces (3) comprise two pairs of parallel steel bars (7,8) which are mutually vertical to form a well-shaped fixing weld to be welded and fixed with a steel plate (9), and a through hole (10) is formed in the center of the steel plate; the two clamping pieces (3) are arranged at both ends of the screw rod (1) in a sleeving manner and are screwed tightly and fixed by the nuts (4).

Owner:MCC5 GROUP CORP SHANGHAI

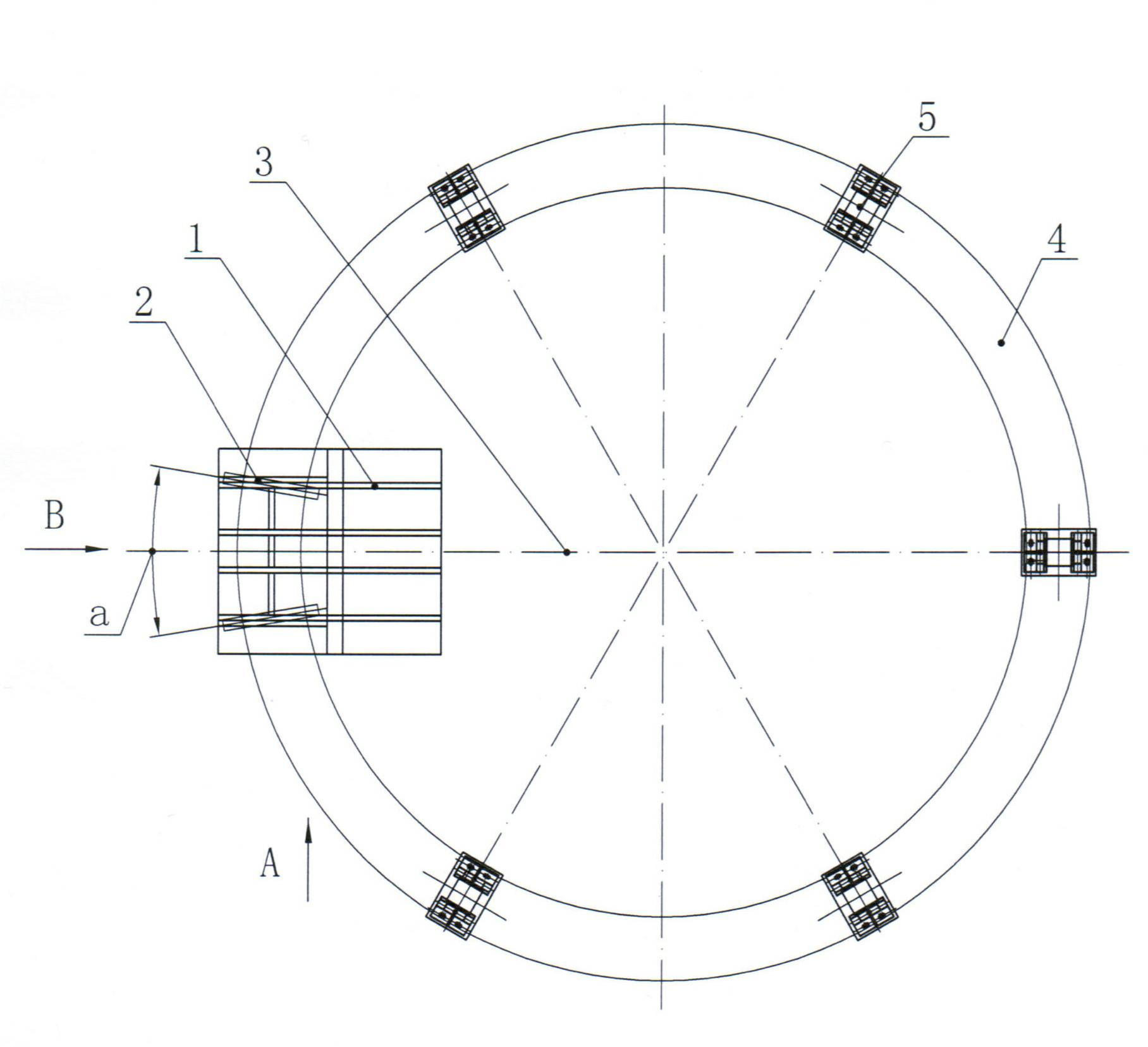

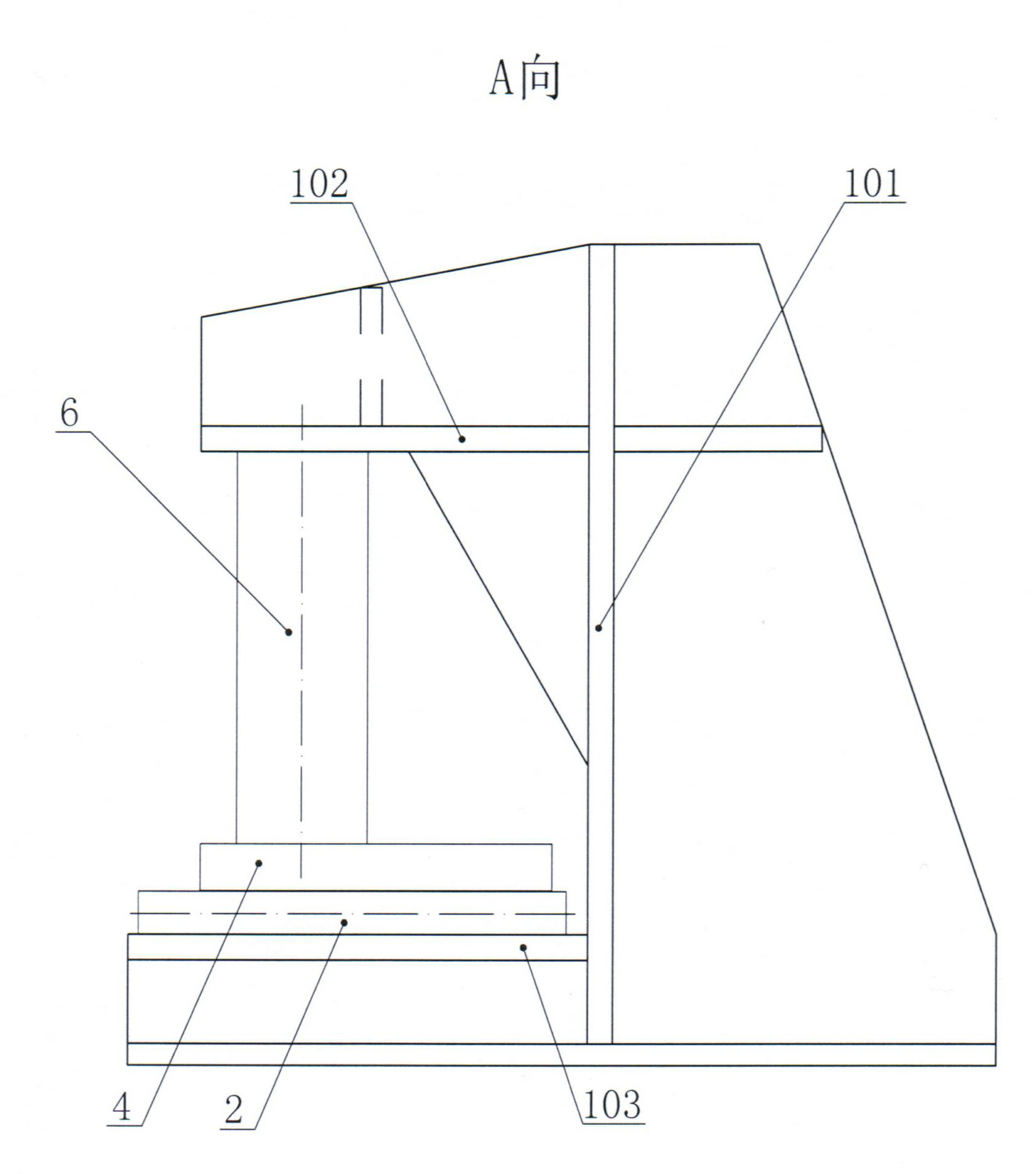

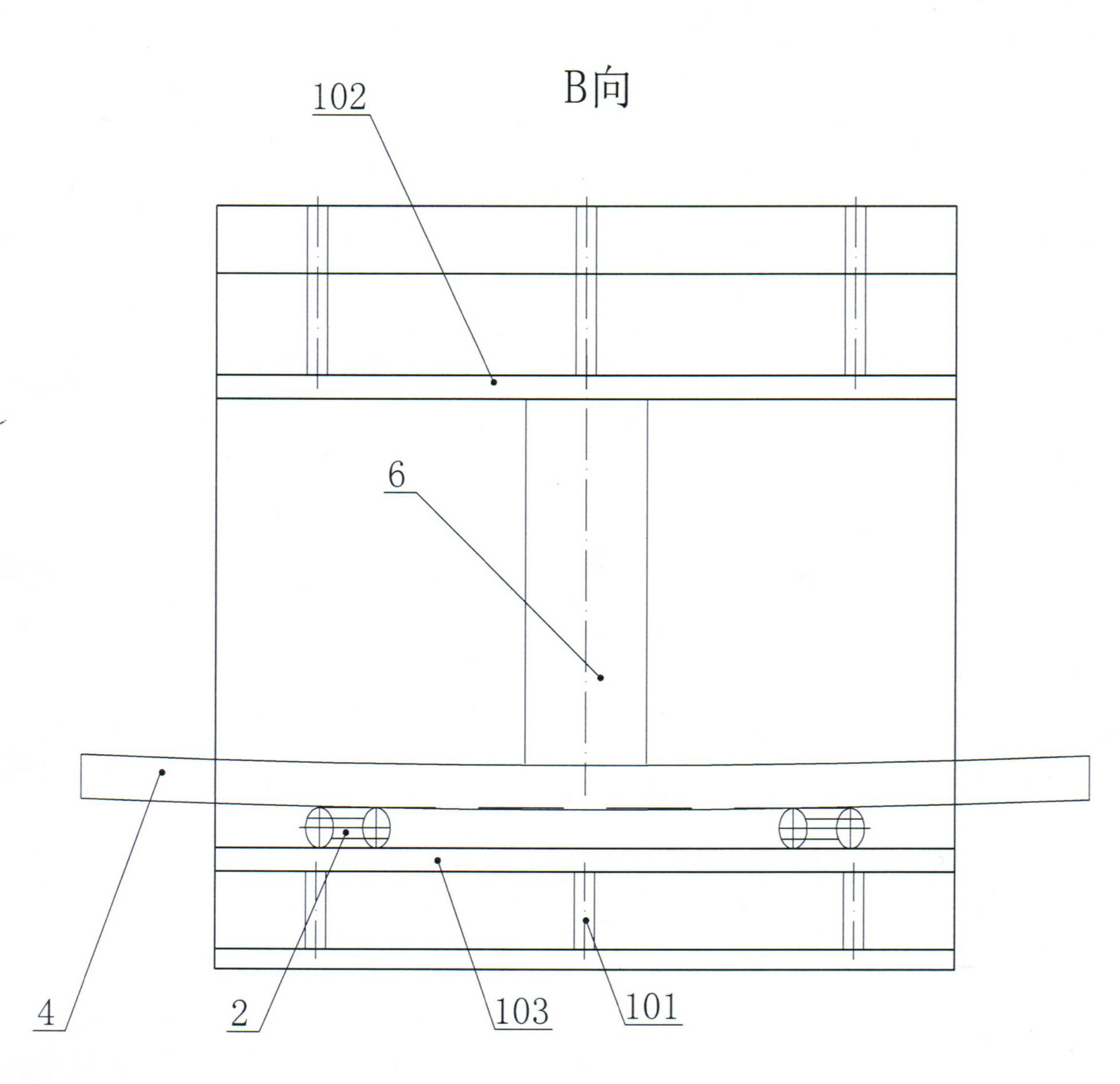

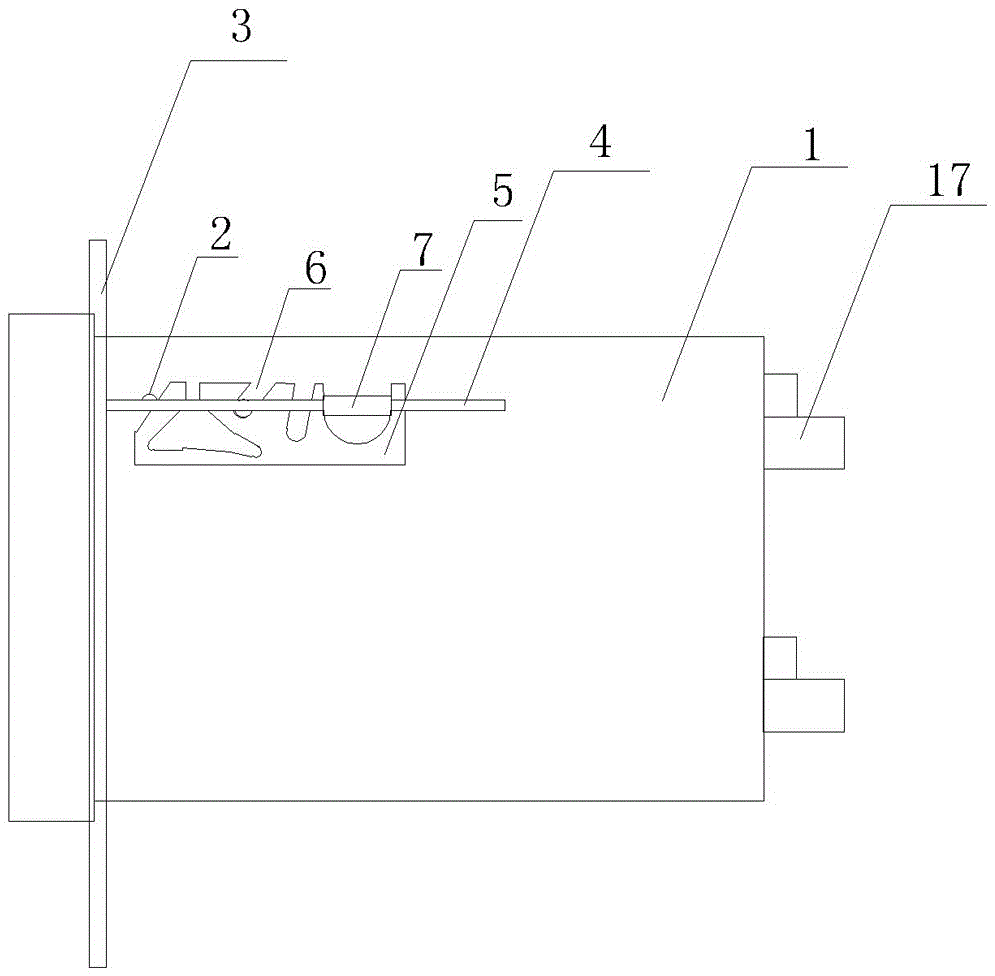

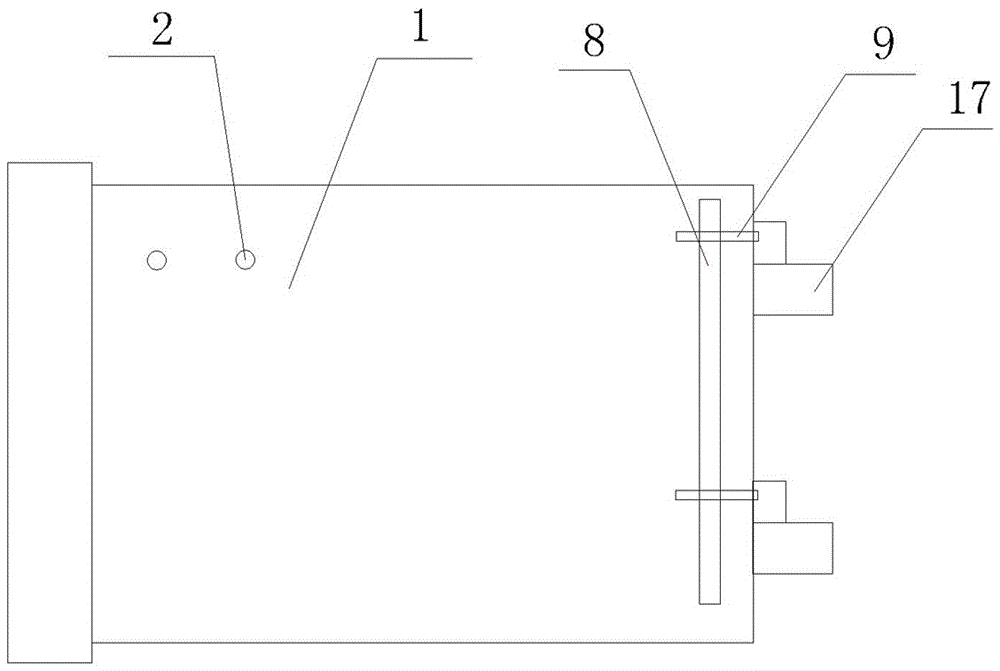

Splicing flange leveling device of wind driven generator tower cylinder

ActiveCN102615147ACalibration is easyImprove the leveling effectWelding/cutting auxillary devicesAuxillary welding devicesWind drivenLeveling effect

The invention relates to a wind driven generator tower cylinder, in particular relates to a splicing flange leveling device of a wind driven generator tower cylinder. The splicing flange leveling device comprises a stand (1), a hydraulic jack (6) and at least two supporting members (2). A splicing flange (4) is positioned among the hydraulic jack (6) and the supporting members (2). The stand (1) comprises an upright post (101), an upper crossbeam (102) and a lower crossbeam (103), and the upper crossbeam (102) and the lower crossbeam (103) are both fixedly connected with the upright post (101). The supporting members (2) are positioned on the lower crossbeam (103) and positioned at both sides of an axis (3) of the splicing flange leveling device. The hydraulic jack (6) is positioned between the splicing flange (4) and the upper crossbeam (102). With the adoption of the splicing flange leveling device, the structure is simple, the leveling operation is convenient, the leveling effect is good, and the quality of a leveled splicing flange is ensured.

Owner:江苏保龙设备制造有限公司

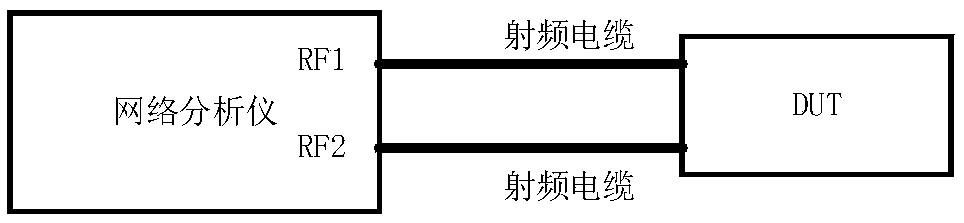

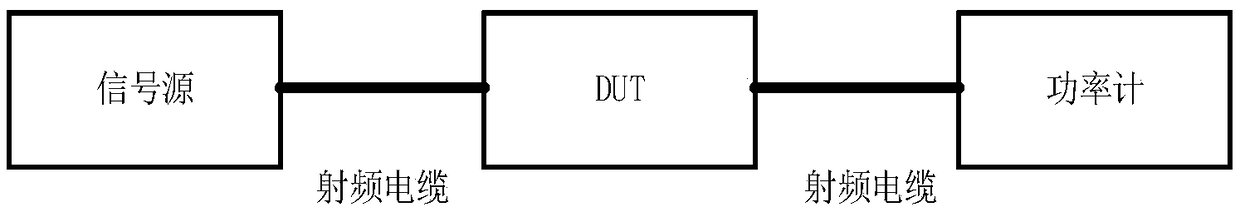

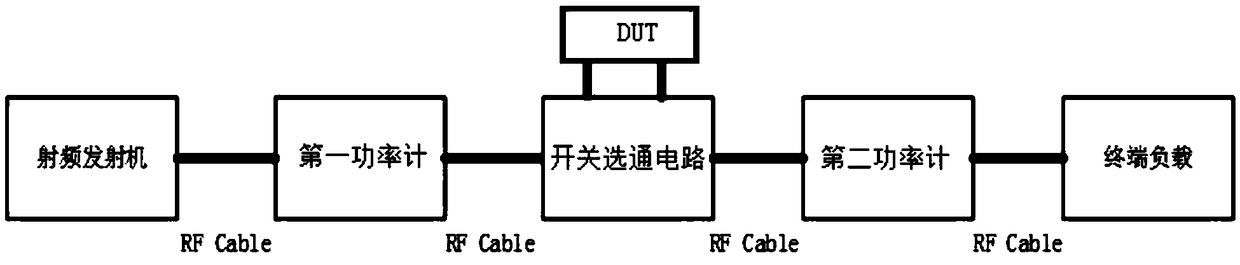

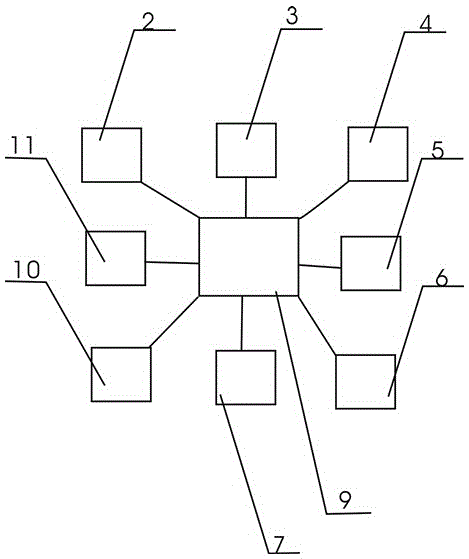

Insertion loss test method and system

InactiveCN108646097AImprove test efficiencyCalibration is easyDielectric property measurementsTest efficiencyRadio frequency

The invention provides an insertion loss test method and system, and belongs to the technical field of loss test. The insertion loss test system includes a radio frequency transmitter, a first power meter, a second power meter and a switch gating circuit, wherein the radio frequency transmitter is connected to the first power meter through a radio frequency cable; the first power meter and the second power meter are each connected with the switch gating switch through a radio frequency cable; the switch gating switch is used for accessing a device to be tested; and the first power meter and the second power meter are used for detecting the input and output power of the device to be tested respectively. The insertion loss test method is implemented based on the insertion loss test system, and includes the following steps: S01, inserting the device to be tested into the insertion loss test system by means of the switch gating circuit; and S02, acquiring the power values of the first power meter and the second power meter, and according to the above power values, calculating the insertion loss Delta S1. The insertion loss test method and system can realize on-line measurement of insertion loss of the device to be tested under the large power matched state of the transmitter and the load, and can also improve the test efficiency.

Owner:PHICOMM (SHANGHAI) CO LTD

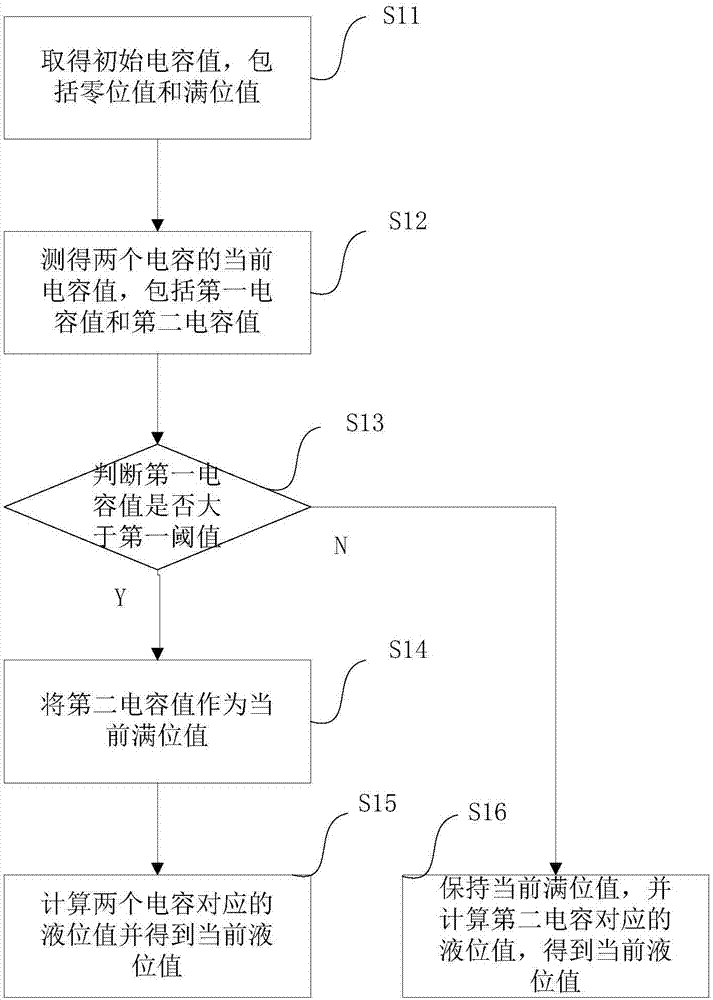

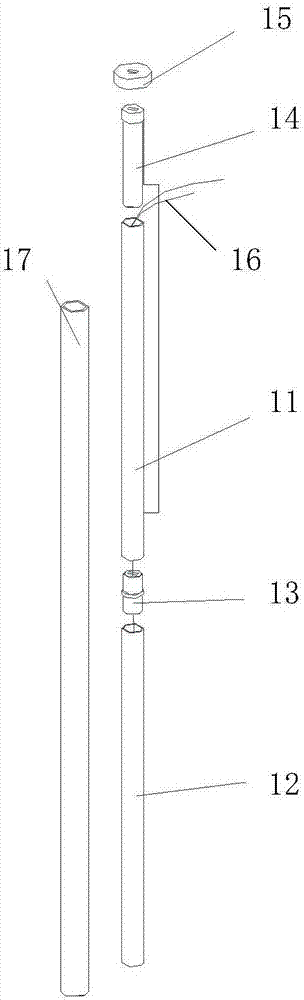

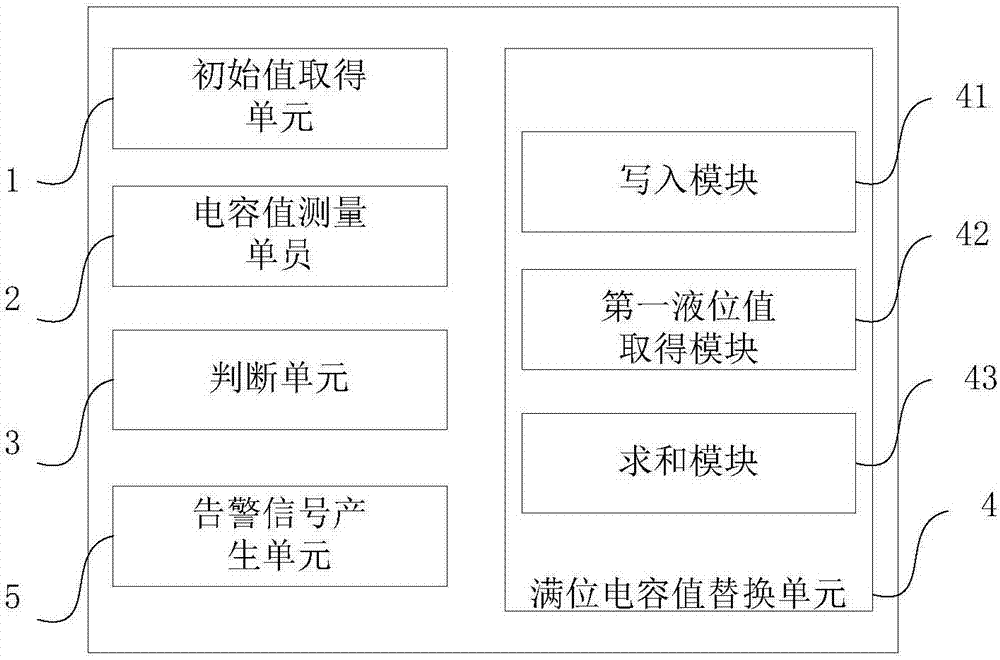

Method for obtaining liquid level data from capacitance level transducer and device

InactiveCN107478295AHigh measurement accuracyEasy CalibrationLevel indicators by physical variable measurementCapacitanceTransducer

The invention relates to a method for obtaining liquid level data from a capacitance level transducer. The method includes the following steps of measuring the capacitance values, including the first capacitance value and the second capacitance value, of the liquid level sensor put in to-be-measured liquid, judging whether the obtained first capacitance value is larger than a set first threshold or not, if yes, executing the next step, if not, comparing a current full-level capacitance value with the obtained second capacitance value and calculating the current liquid level value of the liquid, and comparing the obtained second capacitance value as the current full-level capacitance value with the sum of the first capacitance value and the second capacitance value to obtain the calibrated current liquid level value. The invention further relates to a device for implementing the method. The method and device have the advantages that the measurement accuracy is high and correction operation is simple.

Owner:深圳市鼎丰泰达科技有限公司

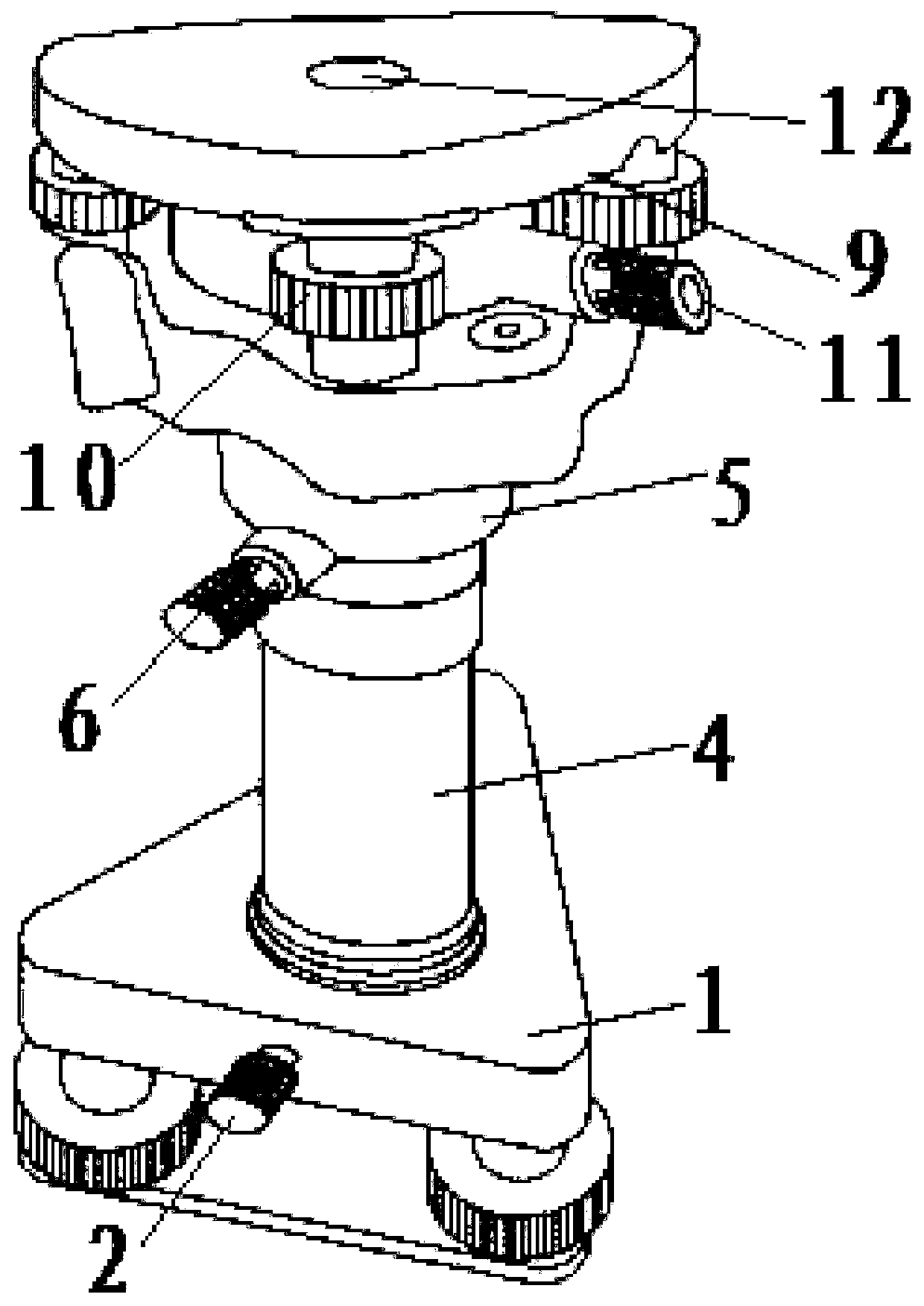

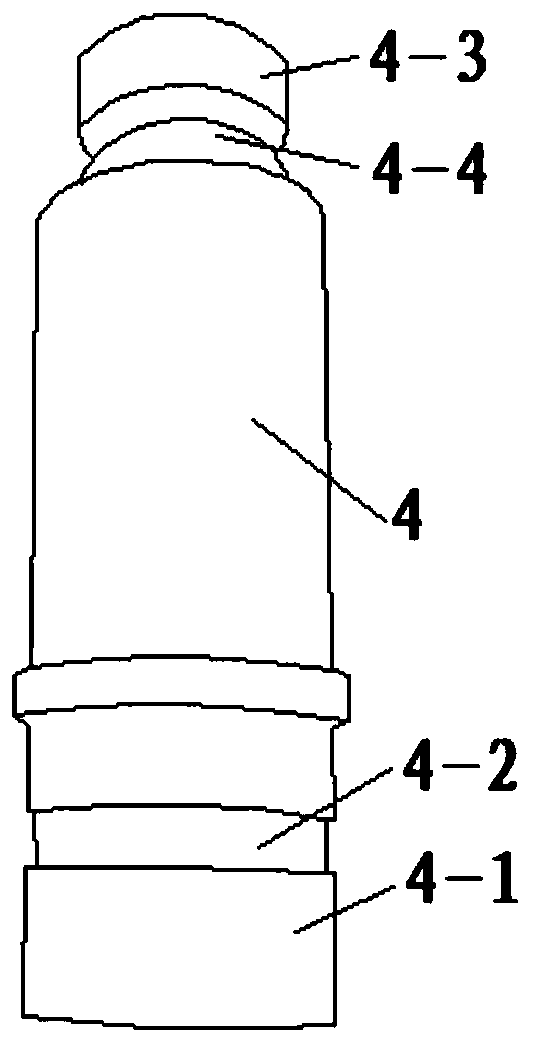

Correction device and method of optical plummet of Leica base

Owner:陕西交通职业技术学院

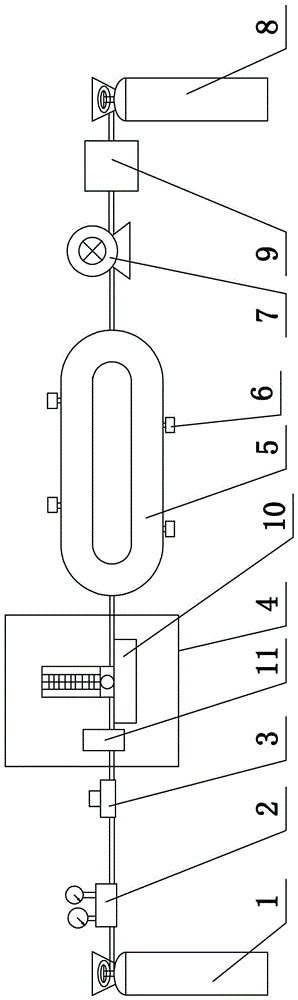

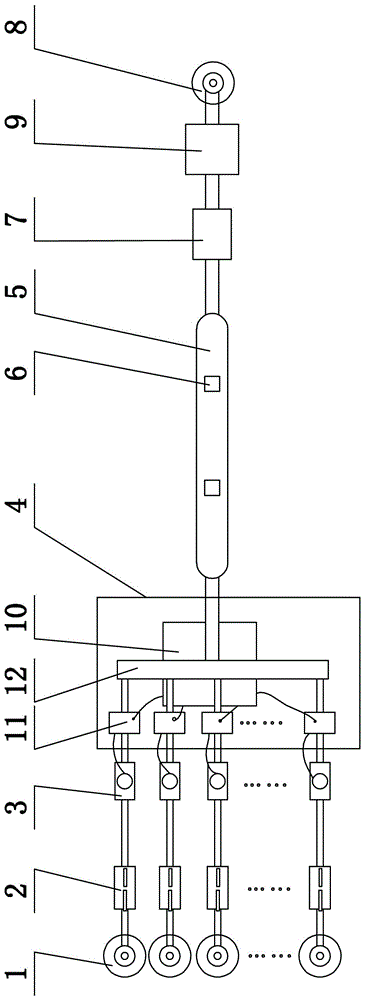

Gas analyzer calibration device

ActiveCN104267154BAvoid wastingSimplify calibration workMaterial analysisGas analysisProcess engineering

The invention relates to a gas analyzer calibration device, comprising a standard gas source, the standard gas source is connected to the air inlet of a gas distribution device through a pipeline, the gas outlet of the gas distribution device is connected to the gas box inlet through a pipeline, and the gas distribution device is a gas analysis device. The instrument calibration provides different concentrations and different types of standard gases. The gas box outlet is connected to the pump inlet through a pipeline, the pump outlet is connected to the gas analyzer to be calibrated, and the gas analyzer outlet is connected to the residual gas recovery device. breath. The invention can automatically configure multiple standard gases of different types and concentrations, and the metering department does not need to purchase a large number of standard gases of different concentrations and types, so that the calibration of the gas analyzer becomes easy, the calibration speed is fast, and the accuracy rate is improved. The operation is simple, and the residual gas recovery device is installed to avoid leakage, thereby avoiding gas waste, cost saving, no pollution to the environment, and no threat to the health of calibration personnel.

Owner:HENAN PROVINCE INST OF METROLOGY

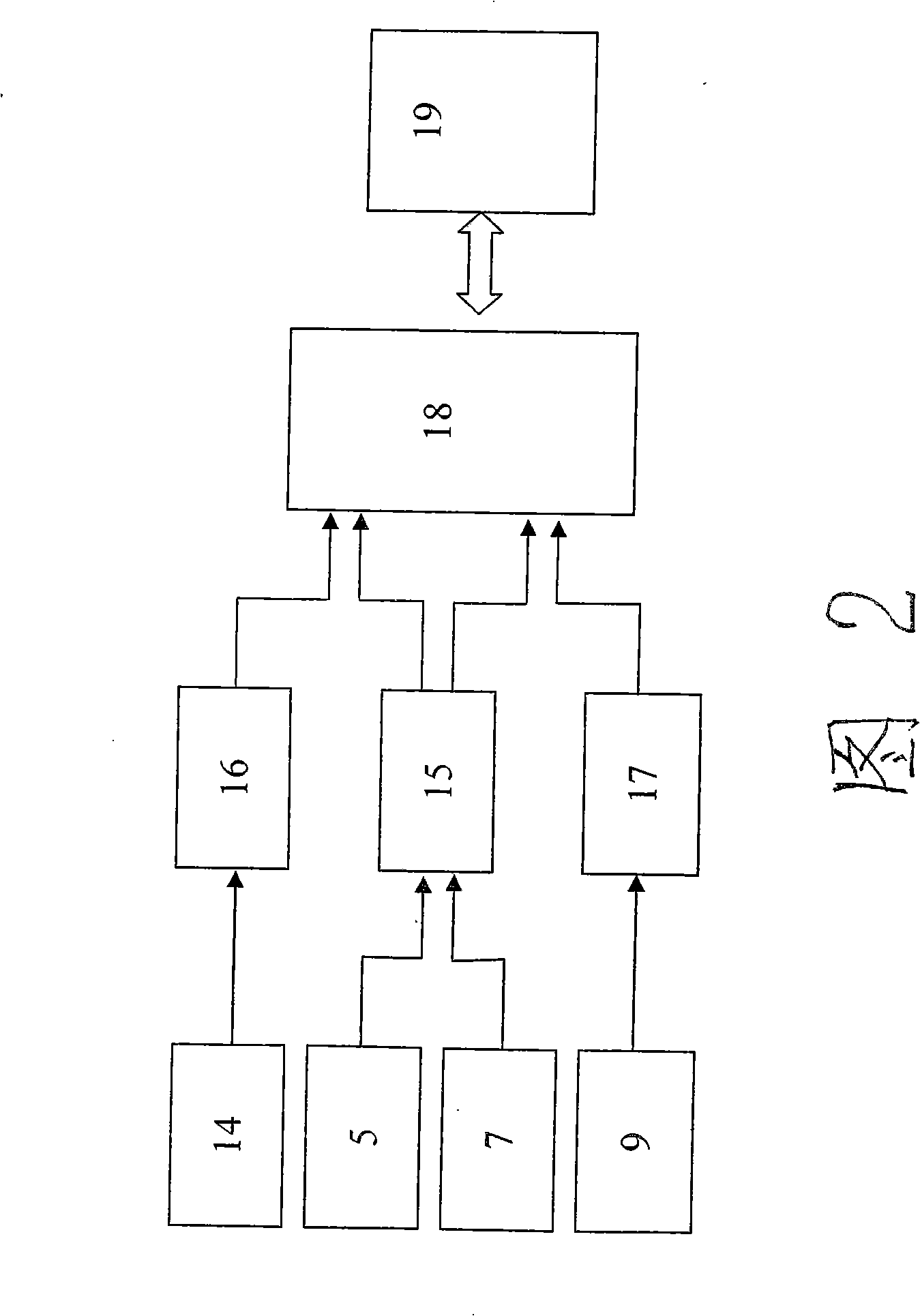

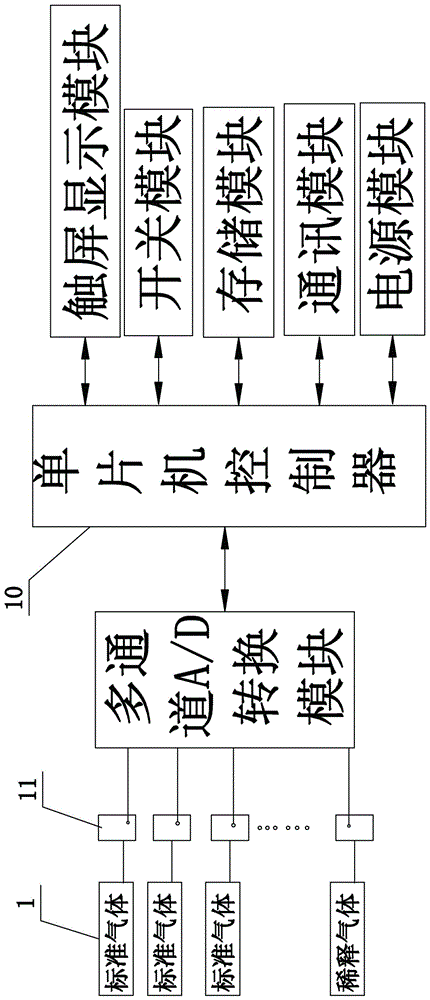

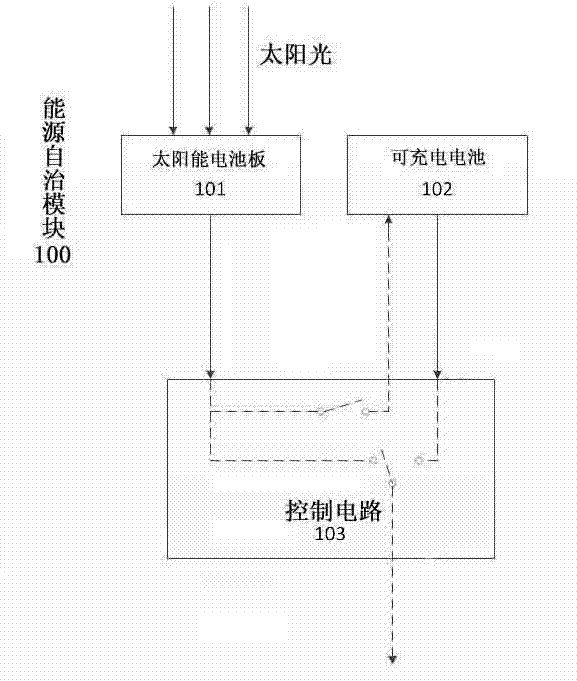

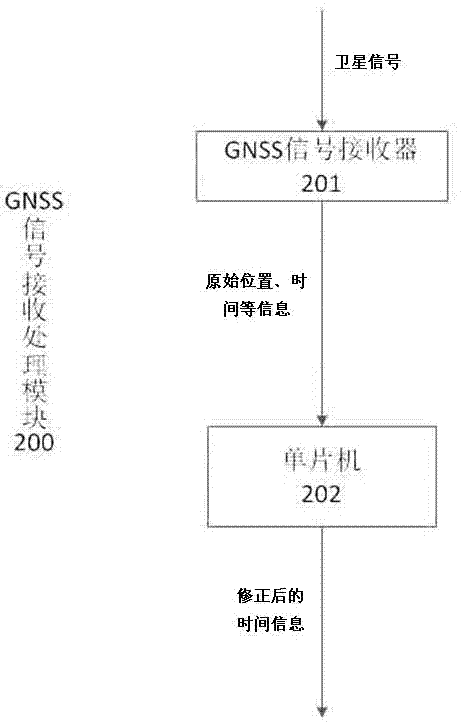

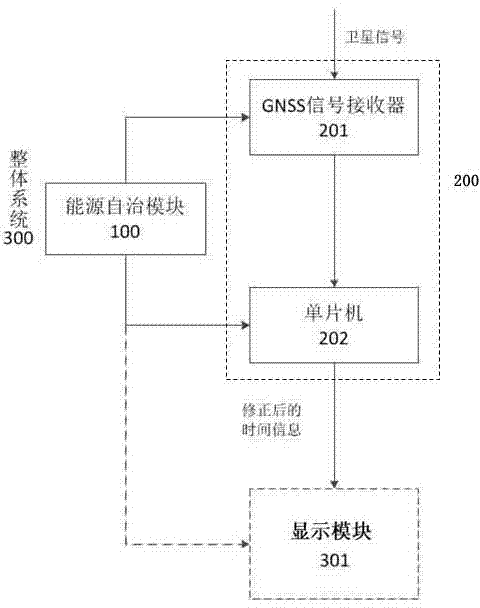

GNSS navigation satellite-based self-maintenance clock publishing system

InactiveCN103365201ANo cumulative errorImprove clock accuracyVisual indicationsRadio-controlled time-piecesSelf maintenanceMarine navigation

The invention discloses a GNSS navigation satellite-based self-maintenance clock publishing system comprising at least a GNSS signal receiving and processing module and at least an energy autonomy module, wherein the GNSS signal receiving and processing module is used for receiving satellite signals and obtaining position information and Greenwich Mean Time, relation between local time and Greenwich Mean Time is determined according to the position information and therefore standard time is automatically corrected, and the energy autonomy module is connected with the GNSS signal receiving and processing module and is used for realizing power source supply of the system. The GNSS navigation satellite-based self-maintenance clock publishing system is characterized in that a GNSS navigation satellite-based self-maintenance and self-synchronization information publishing screen clock is realized; the system is advantaged by simple structure, low manufacture and maintenance cost, and suitability for large scale popularization.

Owner:EAST CHINA NORMAL UNIV +1

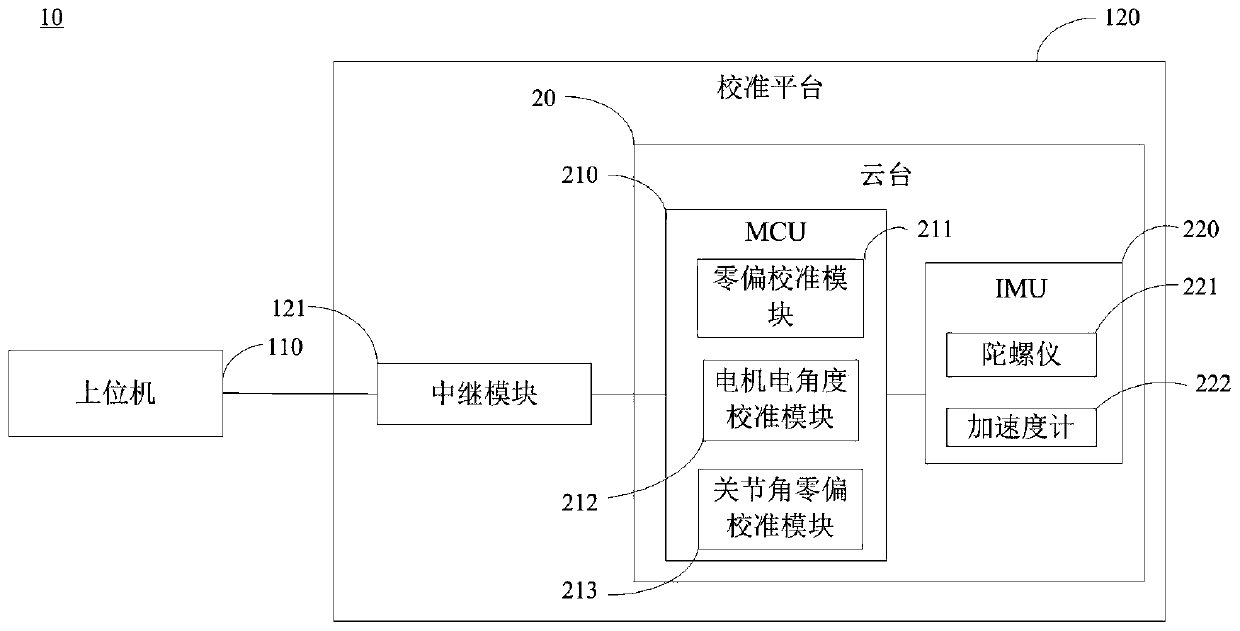

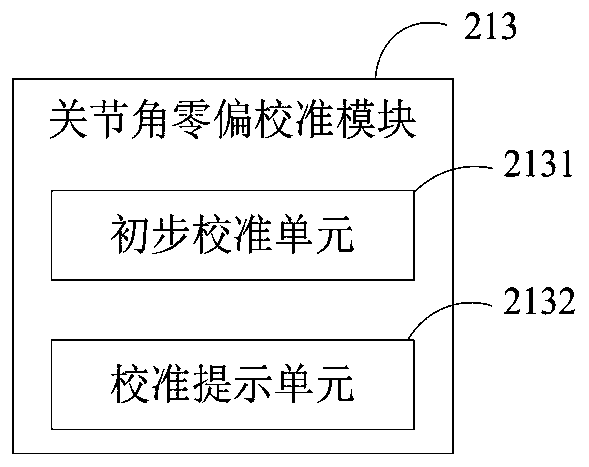

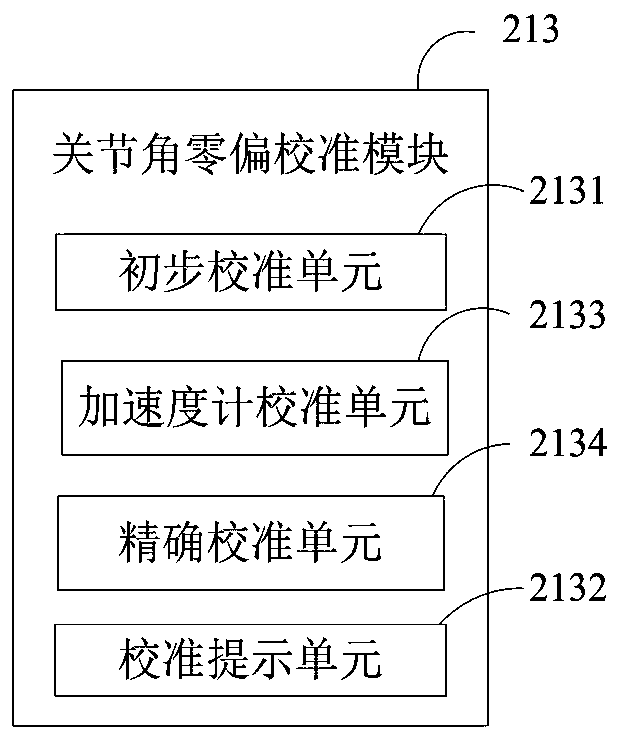

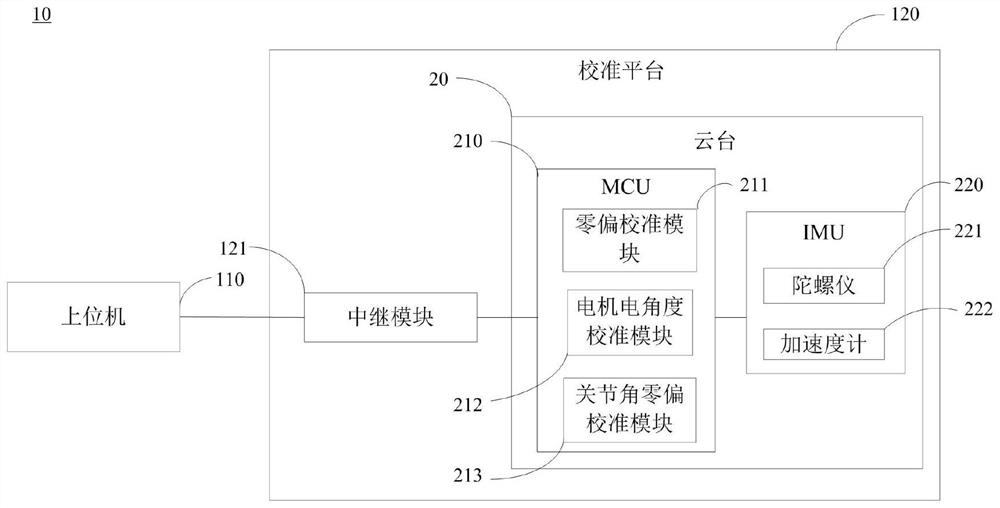

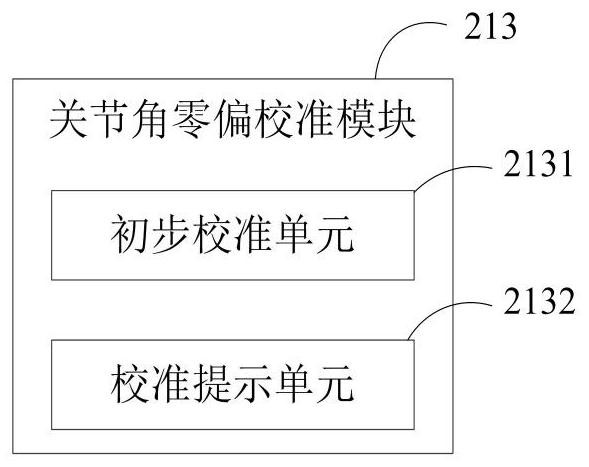

Holder calibration method and calibration system

ActiveCN110553669AReduce manufacturing costCalibration is easyMeasurement devicesComputer scienceTripod head

The invention discloses a holder calibration method and calibration system. The method comprises enabling a to-be-calibrated holder to be placed on a calibration platform which is horizontally arranged, and to form communication connection with a relay module of the calibration platform; and receiving a calibration instruction forwarded by the relay module, and carrying out holder calibration according to the received calibration instruction when the holder is static. The to-be-calibrated holder is placed on the horizontally arranged calibration platform and is in communication connection withthe relay module of the calibration platform to receive the calibration instruction forwarded by the relay module so as to perform automatic calibration, a special jig is not needed, the production cost is reduced, and the calibration operation is simple.

Owner:REMO TECH CO LTD

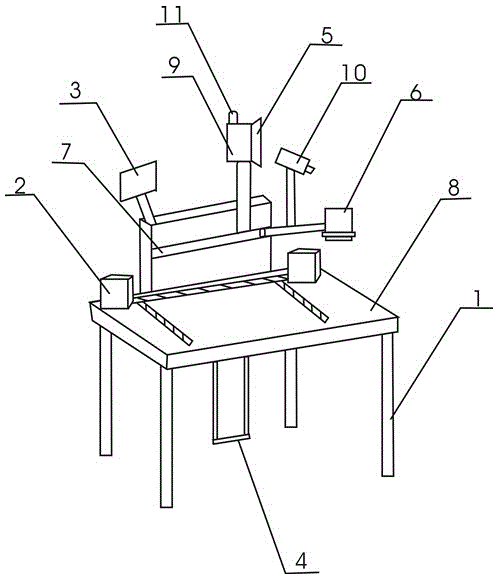

Nameplate printing device for back cover of television set

InactiveCN104999806AAvoid misplacementMake sure the marking is correctTypewritersOther printing apparatusPosition errorEngineering

The invention provides a nameplate printing device for the back cover of a television set. The nameplate printing device is characterized in that the nameplate printing device comprises a bracket, a calibrator, a counter, a driving board, a display screen, a marking device, a movable shaft, a worktable, a controller, a camera and an alarm; the driving board is mounted below the bracket; the worktable is mounted above the bracket; and the calibrator is mounted on the worktable. The nameplate printing device is provided with the calibrator which performs position calibration on a television set housing on the worktable, thereby preventing printing position error in marking, ensuring high accuracy in marking and improving success rate in marking. According to the nameplate printing device, time can be set through the controller for realizing automatic marking; the nameplate printing device is also provided with the driving board through which the marking device can be controlled for performing individual marking, thereby facilitating a user for performing correction operation. The nameplate printing device for the back cover of the television set has advantages of realizing simple structure and quick operation, improving marking precision and shortening production time for the television set housing.

Owner:TIANJIN LIANXINYING PLASTIC TECH

Handheld barcode terminal

InactiveCN103148920ACalibration is easyEasy to operateSpecial purpose weighing apparatusBarcodeComputer science

The invention discloses a handheld barcode terminal. The handheld barcode terminal comprises a body, a mass measurement component arranged on the body, a data processing module and a control component, the mass measurement component is used for measuring the weights of medicines to be taken-inventory, the data processing module is electrically connected with the mass measurement component and can obtain the specification information of the medicines to be taken-inventory, and then the number of the medicines to be taken-inventory is calculated through the weights of the medicine to be taken-inventory. The control component and the mass measurement component are arranged in a separated mode, and through the control component, accuracy calibration can be carried out at least on the mass measurement component. According to the handheld barcode terminal, by the arrangement of the control component, the accuracy calibration can be carried out on the mass measurement component, moreover the control component and the mass measurement component are arranged in the separated mode, so that the control component can be arranged in a structure position where the calibration operation is easy to achieve, and the accuracy calibration process is enabled to be easier to operate.

Owner:SUZHOU IRON TECH

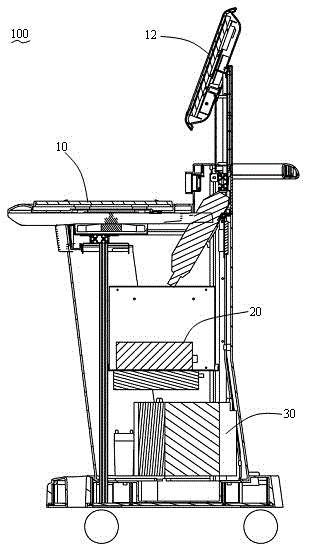

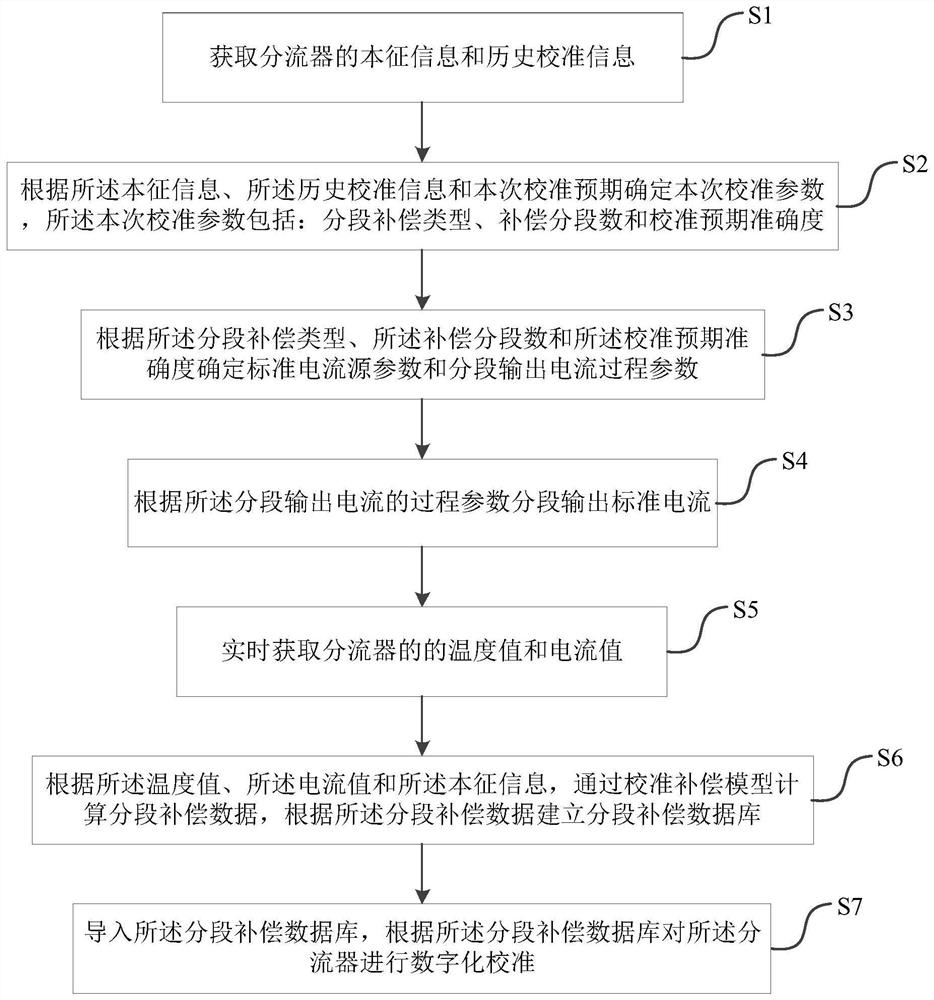

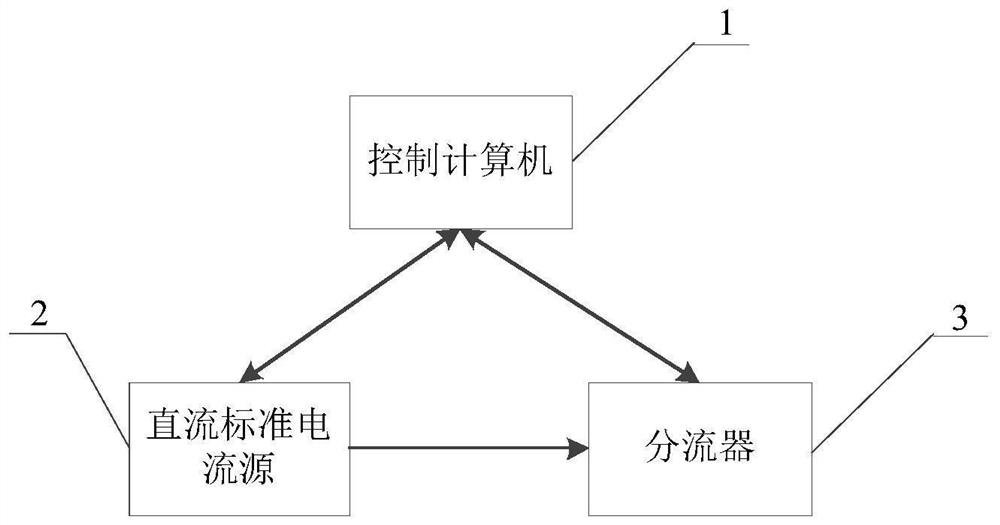

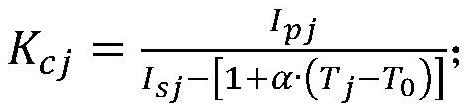

Method and system for automatically calibrating shunt

The invention provides a method and system for automatically calibrating a shunt. The method comprises the following steps: acquiring intrinsic information and historical calibration information of a shunt; determining current calibration parameters according to the intrinsic information, the historical calibration information and the current calibration expectation, the current calibration parameters comprising a segment compensation type, a compensation segment number and calibration expectation accuracy; determining a standard current source parameter and a process parameter of segmented output current according to the current calibration parameter, and outputting a standard current in a segmented manner; acquiring a temperature value and a current value of the shunt in real time; calculating segmented compensation data through the calibration compensation model, and establishing a segmented compensation database; and inputting the segmented compensation database to carry out digital calibration on the shunt. establishing different types of segmented compensation databases by classifying and testing the shunt, and importing the segmented compensation databases of the corresponding types to carry out digital calibration on the shunts. And aiming at batch shunt calibration, the calibration operation can be simplified, the calibration efficiency is improved, and the calibration accuracy and the digital level are improved.

Owner:YUNNAN INST OF MEASUREMENT TEST TECH RES

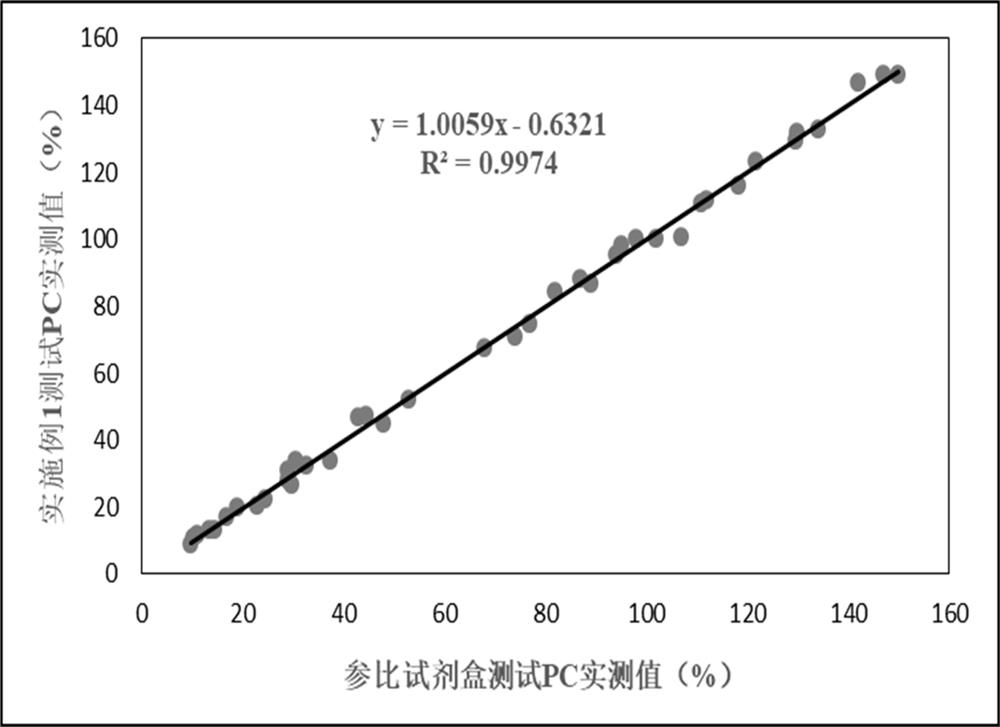

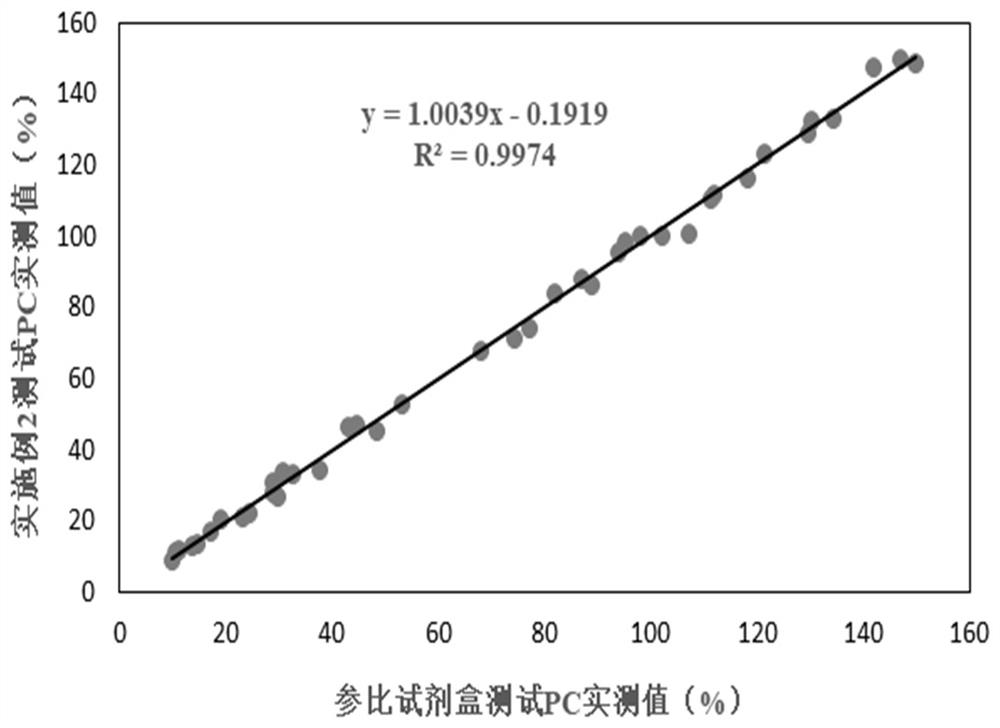

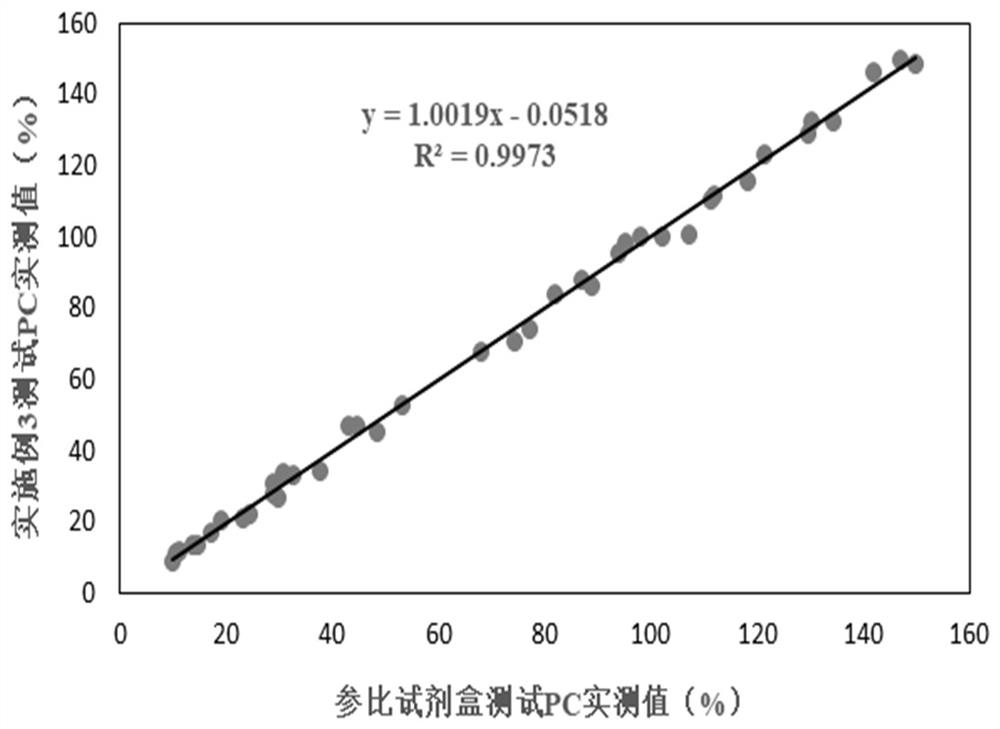

Protein C activity determination kit based on chromophoric substrate method

InactiveCN114814245AHigh sensitivityStrong linear rangeMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementZymogenChromogenic Substrates

The invention discloses a protein C activity determination kit based on a chromophoric substrate method, protein C is a vitamin K dependent plasma serine protease zymogen, and comprises a reagent R1, a reagent R2 and a diluting reagent; the R1 reagent comprises a protein C activator, a first buffer solution and a first auxiliary material; the R2 reagent comprises a chromogenic substrate Pca-5297, a second buffer solution and a second auxiliary material; the diluting reagent comprises a third buffer solution and a third auxiliary material, and the pH of the first buffer solution, the pH of the second buffer solution and the pH of the third buffer solution are 7.2-7.6; the protein C activator and the chromophoric substrate Pca-5297 are matched for use, during detection, the cutting efficiency is high, the reaction signal is strong, the reaction speed is high, the sensitivity is high, the linear range is wide, the reaction time is short, the sample distinction degree is increased, and establishment of the linear range and clinical sample testing are facilitated; the reagent is liquid, convenient to use, low in cost and good in stability.

Owner:SHENZHEN DYMIND BIOTECH

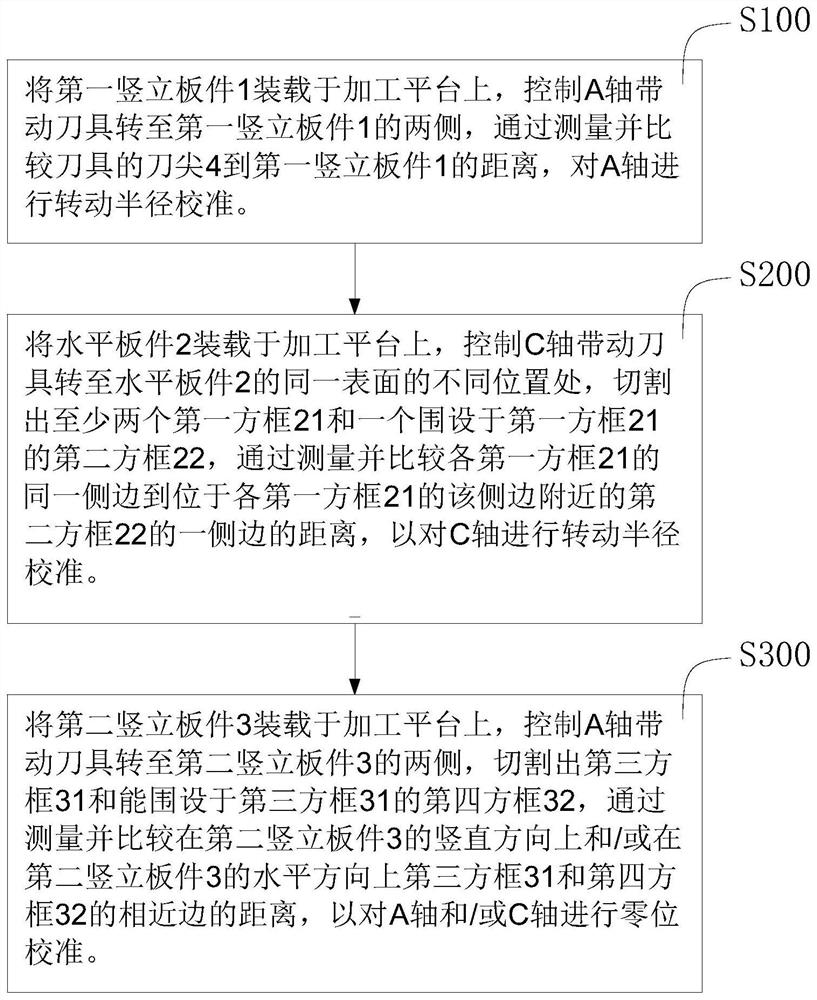

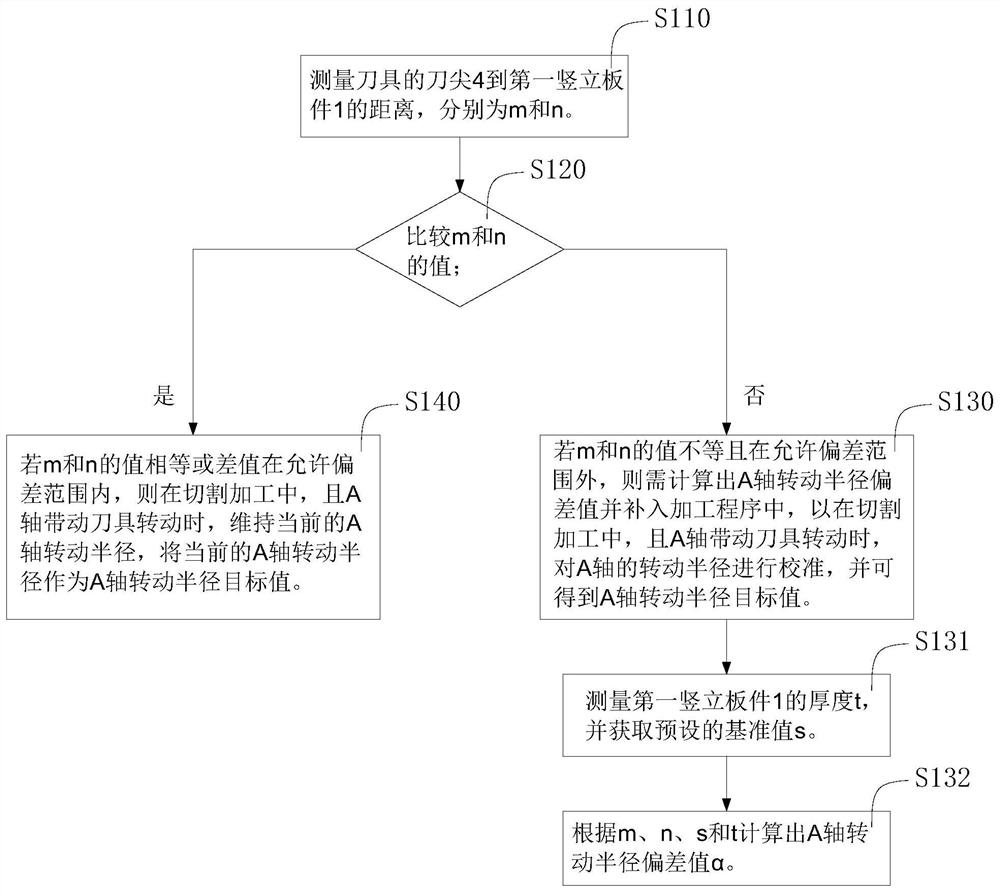

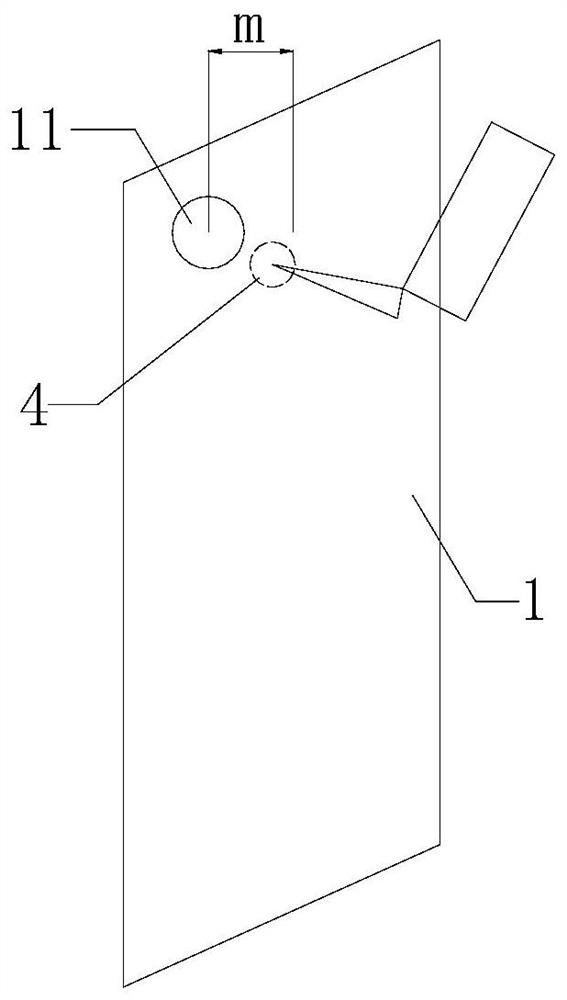

Calibration method for rotating shaft of numerical control machine tool, device, equipment and storage medium

ActiveCN113732818ACalibration is easyHigh precisionAutomatic control devicesMeasurement/indication equipmentsNumerical controlRotational axis

The embodiment of the invention belongs to the technical field of numerical control machining centers, and relates to a calibration method for a rotating shaft of a numerical control machine tool. The method comprises the following steps that rotating radius calibration is carried out on an A shaft by measuring and comparing the distance from a tool nose of a tool to a first vertical plate; rotation radius calibration is carried out on C shaft by measuring and comparing the distance from the same side edge of each first square frame to a position located on one side edge of each second square frame cut on a horizontal plate; and zero position calibration is carried out on the A shaft and / or the C shaft by measuring and comparing the distance between the close edges of a third square frame and a fourth square frame cut on a second vertical plate. The embodiment of the invention further provides a numerical control machining device, equipment and a storage medium. According to the embodiment of the invention, the positions between the A shaft and the C shaft and the plates are changed by rotating the A shaft and the C shaft, the distances between the plates at different positions are measured, or the distances between the plates at different positions after cutting are measured, rotation radius calibration and zero position calibration are carried out on the A shaft and the C shaft, the calibration operation in the whole process is simple, the method is efficient and novel, and the precision is relatively high.

Owner:HANS LASER TECH IND GRP CO LTD +1

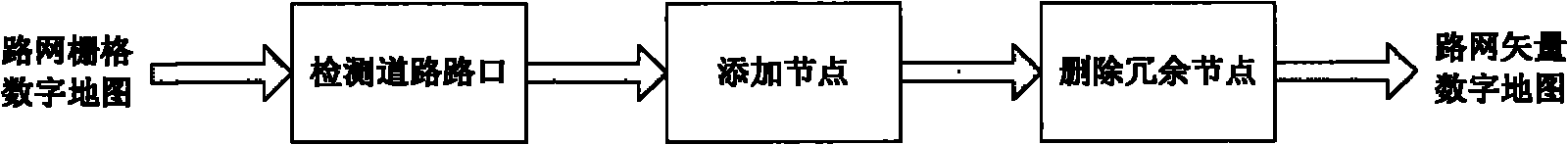

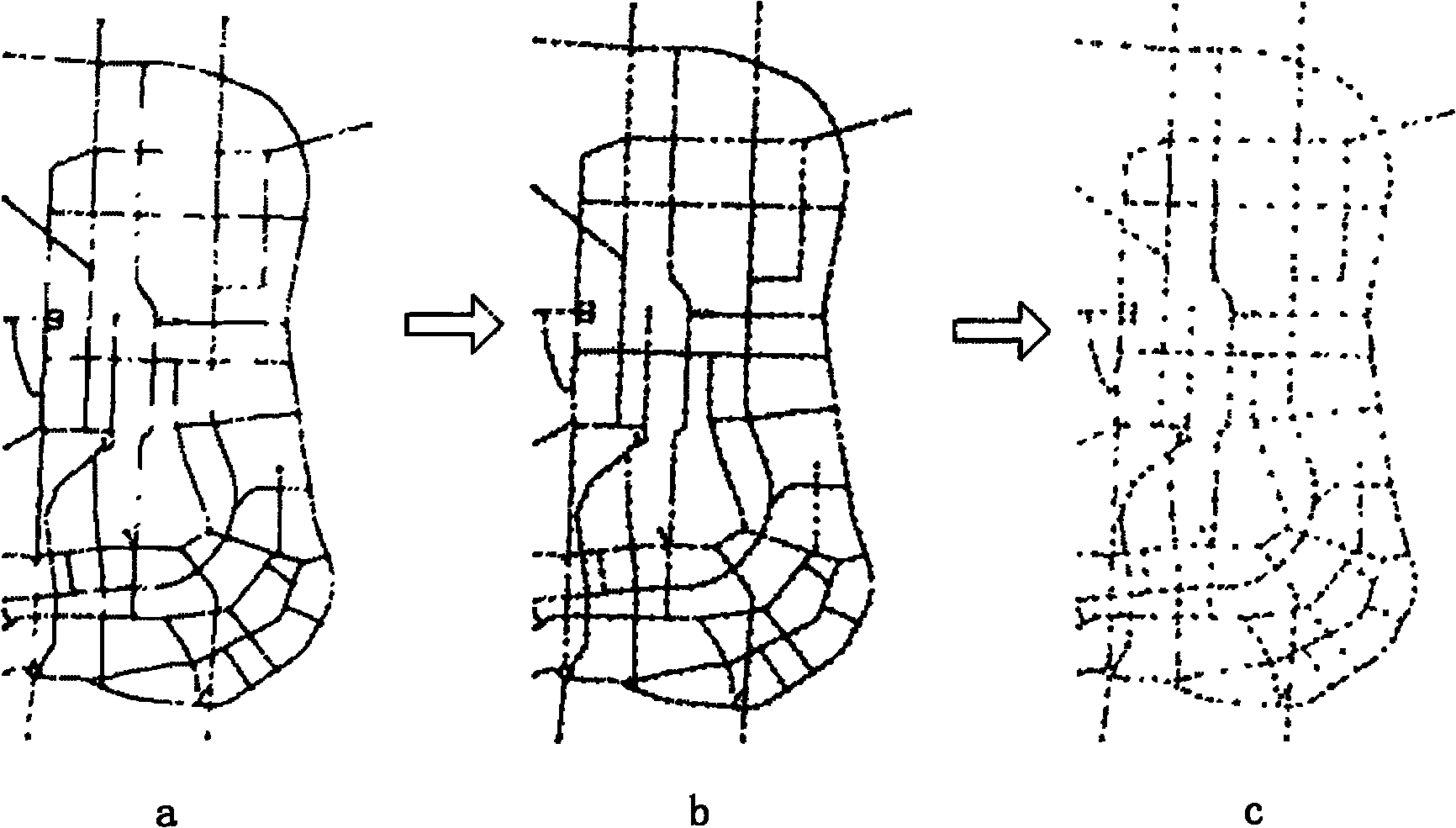

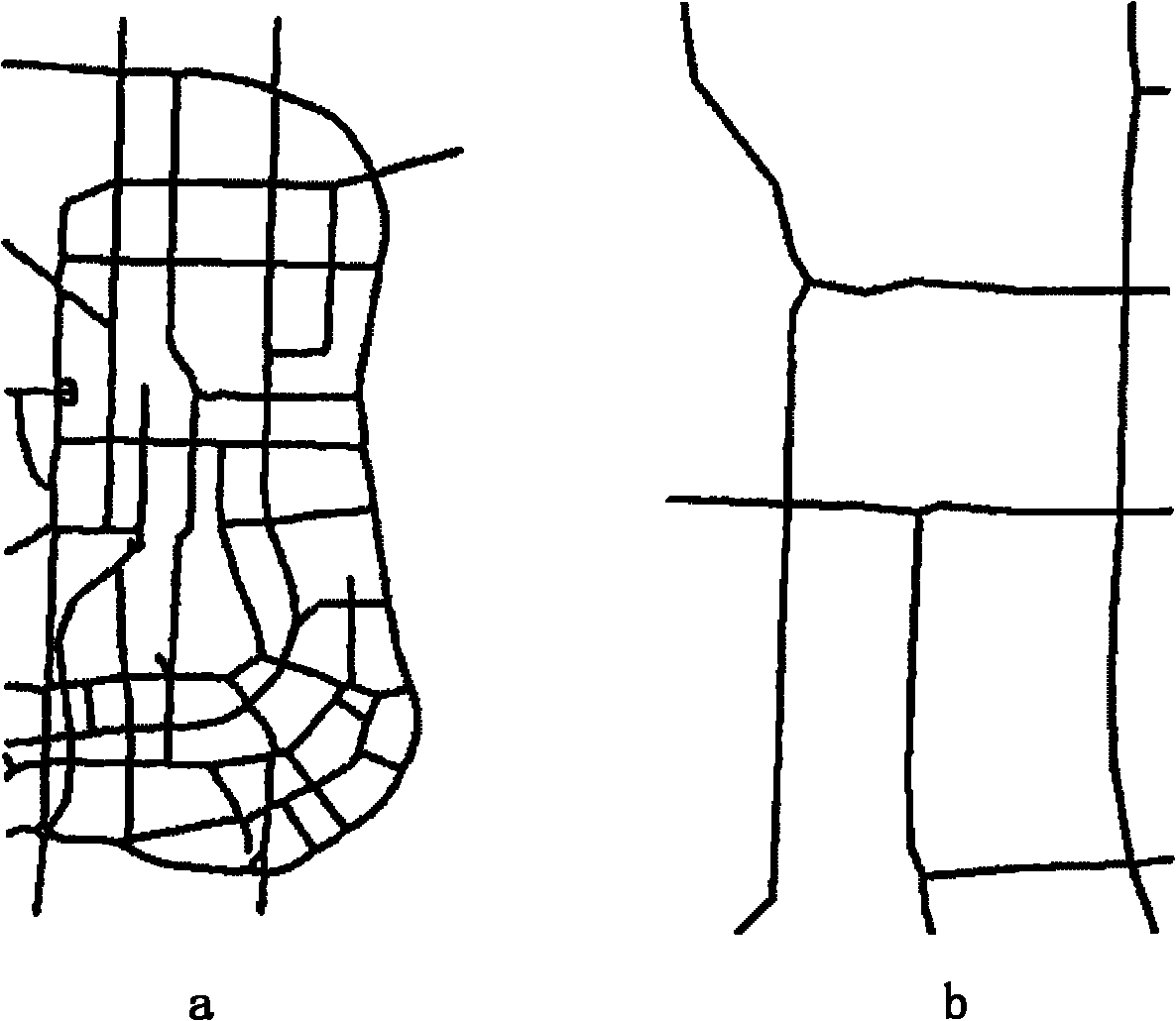

Method for automatic vectorization of road network digital raster map

InactiveCN101630463BCalibration is easyPromote conversionInstruments for road network navigationMaps/plans/chartsGraphicsImaging processing

The invention relates to a method for the automatic vectorization of a road network digital raster map in the technical field of image processing. Firstly, the road network digital raster map is read into a computer memory, a road crossing on a road network image, which comprises a crossed road crossing and a road terminal, is detected, and pixels consisting of the road crossing are marked; secondly, each road crossing is used as a center to detect an adjacent road crossing, a pixel chain from the road crossing to each adjacent road crossing is formed simultaneously, and nodes are added at intervals to each pixel chain, thereby obtaining pattern points recording the shape of a road; and finally, redundant nodes which are added in the step two are deleted, and a vectorization result is preserved according to the normal vector map format. The road network vector digital map formed by the invention can bring great convenience for the operation of locus correction of an intelligent transportation system and a vehicle navigation system.

Owner:SHANGHAI JIAOTONG UNIV

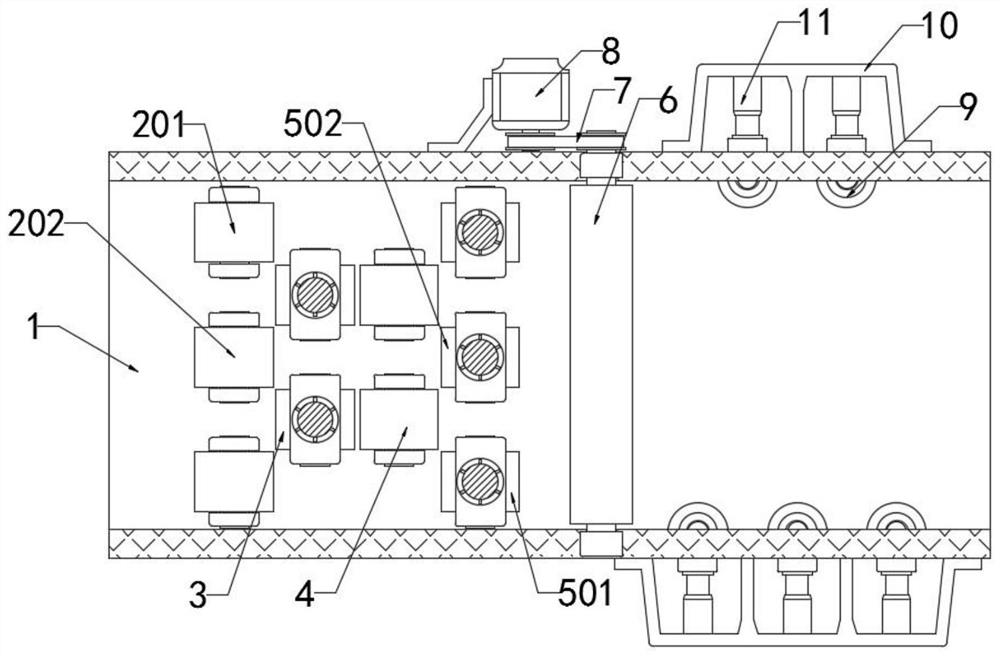

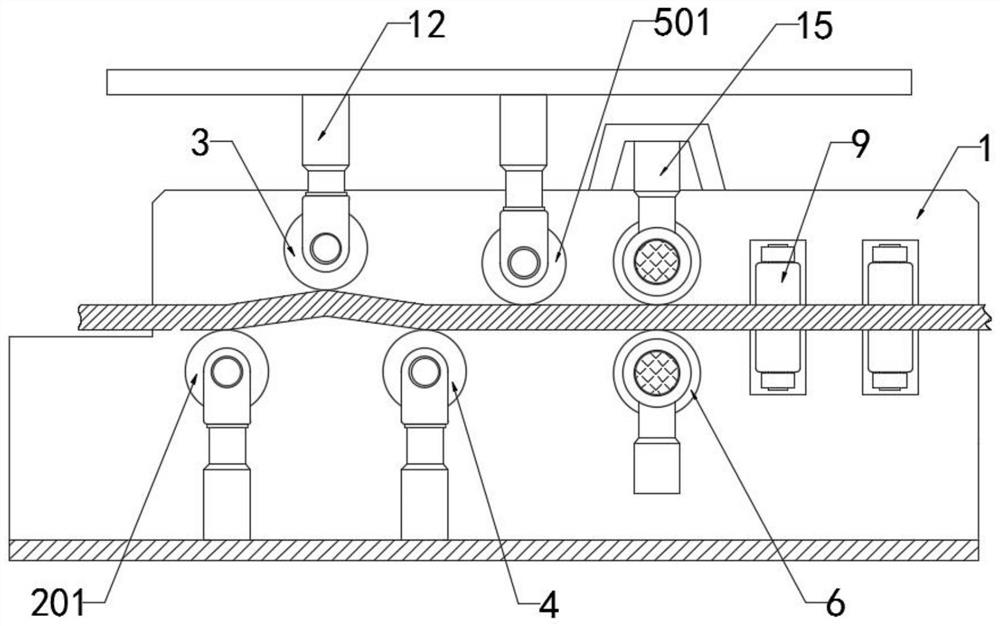

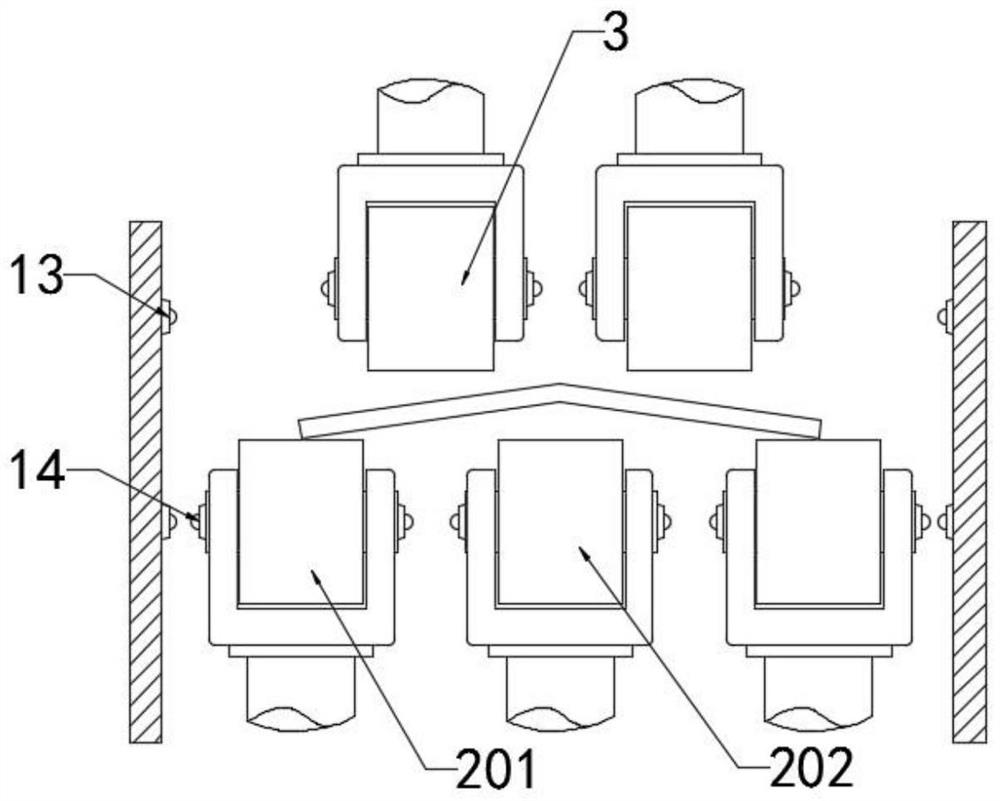

Multi-cylinder hydraulic correction equipment

PendingCN114178346ACalibration is easyImprove applicabilityMetal working apparatusMechanical equipmentControl engineering

The invention relates to the technical field of mechanical equipment, and discloses multi-cylinder hydraulic correction equipment which comprises a correction box, and a first correction set, a second correction set, a third correction set and a fourth correction set are sequentially arranged above the correction box in the horizontal direction of an overlooking face. First hydraulic cylinders used for position transmission are arranged below the first correction set and the third correction set and above the second correction set and the fourth correction set, the first correction set, the second correction set and the third correction set are arranged at intervals, and the first correction set corresponds to the fourth correction set in position. According to the correcting device, the four correcting sets are arranged at intervals, the upper correcting set and the lower correcting set are matched with each other, and the adjusted position of the workpiece is changed through the forward driving force of the driving roller on the workpiece, so that the workpiece is conveniently corrected in the running process, and the applicability of the correcting device is improved.

Owner:安徽容众自动化设备有限公司

A frame column edge protection angle steel installation correction tool and manufacturing method thereof

ActiveCN103967042BSimple structureEasy to manufactureFoundation engineeringBuilding material handlingEngineeringScrew thread

The invention relates to a mounting correction tool for a protection corner angle of a frame column. The tool comprises a screw rod (1), a square pillar (2) and two clamping pieces (3). The tool is characterized in that the screw rod (1) is a screw rod with the diameter of 12 to 16mm, the screw rod is made of round steel, the length of the screw rod is 200mm longer than that of the sectional dimension of the mounted frame column, threads which are formed in both ends of the screw rod are matched with fixing nuts (4), and a plurality of small holes for allowing iron nails (6) to pass through are drilled in the middle part; the length of the square pillar (2) is 5mm longer than that of the sectional dimension of the mounted frame column, and the small holes of the screw rod (1),through which the iron nails (6) pass, are connected and fixed with the screw rod (1); the clamping pieces (3) comprise two pairs of parallel steel bars (7,8) which are mutually vertical to form a well-shaped fixing weld to be welded and fixed with a steel plate (9), and a through hole (10) is formed in the center of the steel plate; the two clamping pieces (3) are arranged at both ends of the screw rod (1) in a sleeving manner and are screwed tightly and fixed by the nuts (4).

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

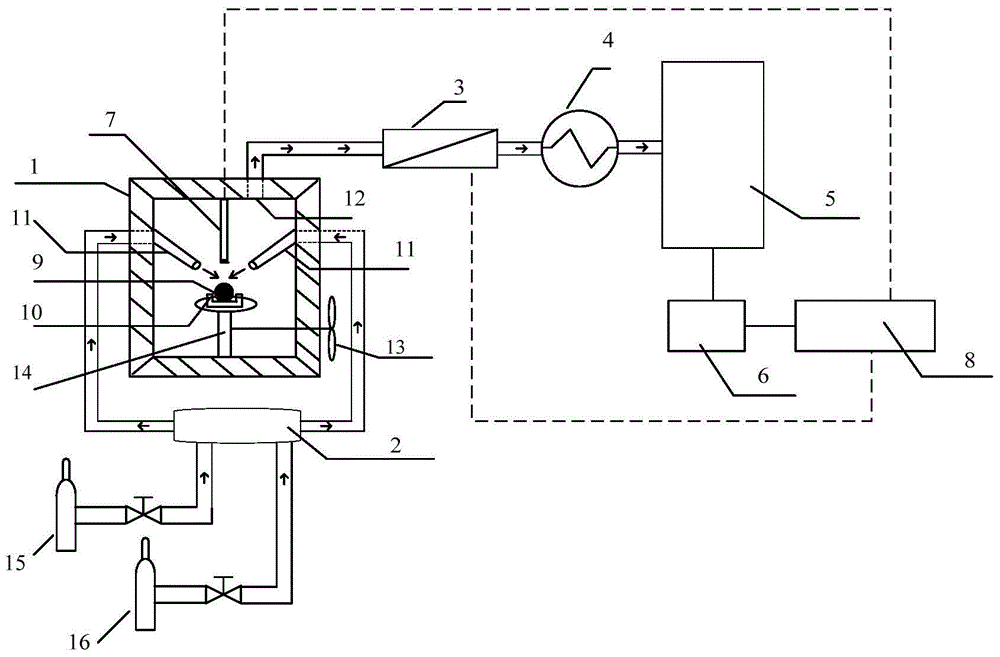

A device for measuring mercury content in coal

ActiveCN104330374BQuick measurementLarge measuring rangePreparing sample for investigationColor/spectral properties measurementsPersonal computerProcess engineering

The invention provides a coal mercury content measuring device. The coal mercury content measuring device comprises a flowmeter, a converter for Hg2+, a mercury analyzer, an A / D converter, an industrial personal computer and a smoke generator, wherein the flowmeter and the converter for Hg2+ are connected with the mercury analyzer by use of conduits; the smoke generator comprises a smoke generation furnace and a gas fuel supply system which comprises a CO gas tank, an O2 gas tank, a mixed gas chamber and fuel nozzles; the fuel nozzles are symmetrically arranged on the inner wall of the smoke generation furnace; a holder is mounted at the bottom of the smoke generation furnace; a coal sample vessel is arranged above the holder and a coal sample is put into the coal sample vessel; a thermocouple is arranged on the top of the smoke generation furnace and a flow through hole is formed in the top of the smoke generation furnace; the flow through hole is connected with the flowmeter by use of a conduit. The coal mercury content measuring device has the advantages of simplicity and convenience in calibration, large measurement range, short detection time and the like; the coal mercury content measuring device is capable of realizing quick measurement on the mercury content in the coal and is especially suitable for measuring the mercury content in the commercial coal.

Owner:TSINGHUA UNIV

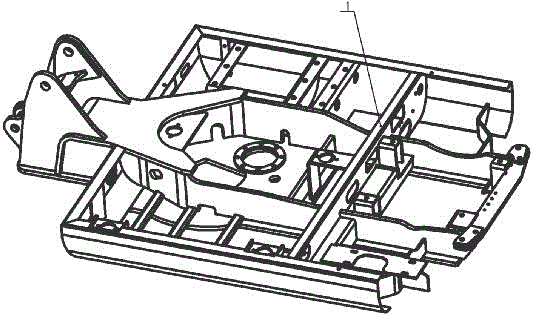

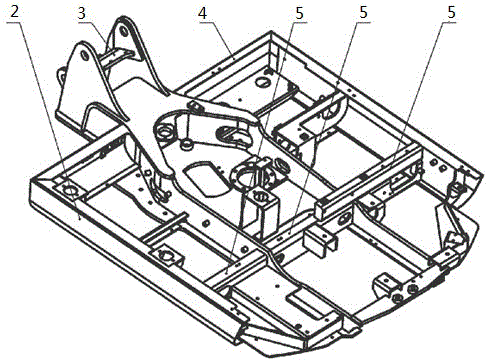

Miniature excavator rotation frame

InactiveCN104088322AEasy production and installationCalibration is easySoil-shifting machines/dredgersPhysicsEngineering

The invention discloses a miniature excavator rotation frame which comprises a left frame, a top frame, a right frame and beams. The miniature excavator rotation frame is characterized in that an original frame is changed to be in a joint type from an overall type and divided into the left frame, the top frame and the right frame in a three-joint mode, wherein the left frame, the top frame and the right frame are connected together in a buckling, or embedding or welding mode, an original middle beam is changed to be in a three-joint mode, and the three beams are connected together in a buckling, or embedding or welding mode. The line production is easy to achieve, the takt is intense, the errors are small, part deformation is small, and the strength is high.

Owner:黄健

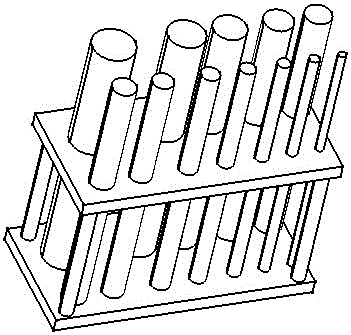

A calibration device for measuring instrument of steel protective layer

ActiveCN104296711BMeet thickness requirementsSimple structureMeasurement devicesCalibration resultRound bar

The invention discloses a calibration device for a cover protectometer. The calibration device comprises a protective layer standard block and standard round rods, the protective layer standard block is made of non-magnetic materials and is of a square structure, through holes are formed in the upper end face, a calibration working plane is arranged on the lateral face, the standard round rods are arranged in the through holes, and the protective layer standard block is in detachable connection with the standard round rods. The series of standard round rods and the protective layer standard block provided with the series of standard round rods are adopted in the calibration device for the cover protectometer, the calibration of the instruments like reinforcement cover thickness measurement instruments can be achieved, the calibration process is simple and convenient, and the calibration result is accurate and effective. The calibration device is simple in structure, the standard round rods and the protective layer standard block are designed in a separated mode, independent oil seal protection can be conducted on reinforcing steel bars, corrosion of the reinforcing steel bars is avoided, and the calibration device is more stable.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

High precision low maintenance pH meter

InactiveCN106501328AImprove the impedance effectImprove signal anti-interference abilityMaterial electrochemical variablesMechanical stabilityEngineering

The invention discloses a high precision low maintenance pH meter, which includes a shell, a wiring terminal structure and components as well as a signal acquisition and processing system. The wiring terminal structure includes a signal terminal board and a signal terminal, the signal terminal board and the components are located in the shell, the wiring end of the signal terminal is located outside the shell, the front of the shell is provided with a hanger, and the front side of the signal terminal board is equipped with a signal shielding aluminum cover. The high precision low maintenance pH meter provided by the invention not only can protect components and the circuit from external liquid and gas corrosion, but also has the characteristics of convenient production and processing, low making cost, convenient installation and wiring, good heat dissipation effect, good mechanical stability, and wide application range, can "see" the measurement balance point of a sensor very visually, can judge the sensor performance visually, reduce the requirement for the professional skills of users, and improve the correction accuracy and measurement accuracy, lower the probability of incorrect use of a correction solution during correction, and especially can achieve better effect under an outdoor measurement condition and in high precision requirement measurement fields.

Owner:杭州美尼特自动化仪表有限公司

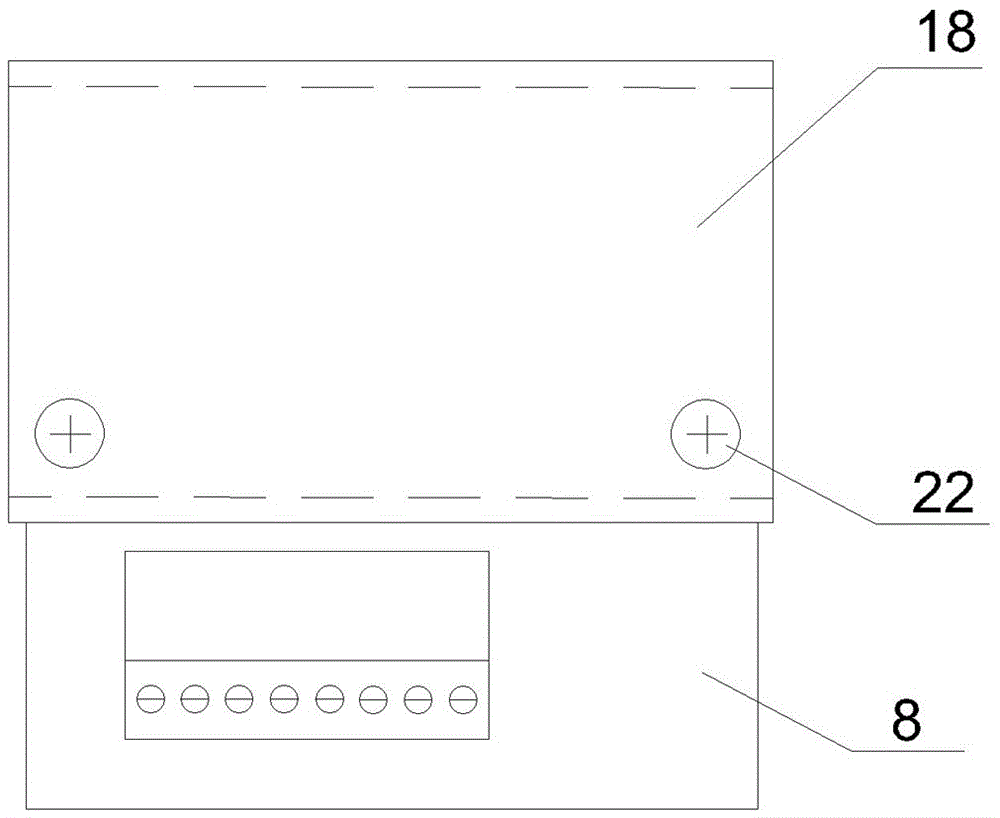

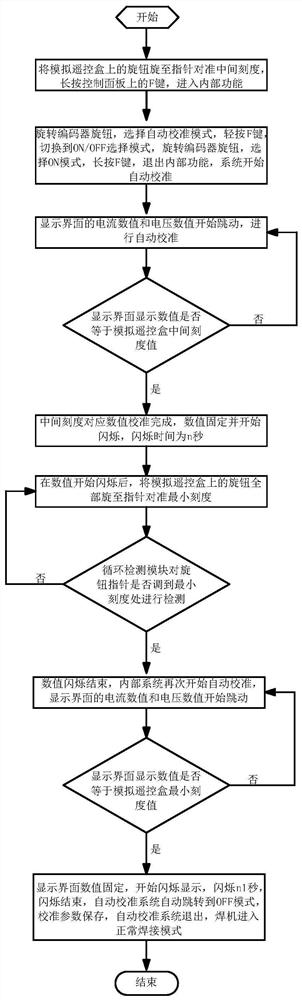

An automatic calibration system for an analog remote control box and an automatic calibration method for an analog remote control box

ActiveCN111610480BHigh precisionReduce output errorElectrical measurementsRemote controlControl engineering

The invention discloses an automatic calibration system for an analog remote control box and an automatic calibration method for an analog remote control box. The automatic calibration system of the analog remote control box is installed in the internal function of the welding power source. The specific operation method includes: Step 1, align the pointer to the middle scale, and press and hold the F key to enter the internal function of the welding machine; Step 2, select the automatic calibration system and switch to ON mode, start calibration; step 3, stop beating when the displayed value is consistent with the value on the middle scale, and the value starts to flash; step 4, after the value starts to flash, turn all the pointers to the minimum scale, and start automatic calibration again; step 5 , when the displayed value is consistent with the minimum scale value, it stops beating, and the value blinks. After the blinking, the automatic calibration system jumps to OFF mode, the calibration parameters are saved, the system exits, and the welding machine enters the normal welding mode. The invention can realize the automatic calibration of the analog remote control box, which is beneficial to improving the precision of the analog remote control box and improving the welding effect.

Owner:OTC ELECTROMECHANICAL QINGDAO CO LTD

Connection establishment failure reporting method and user equipment

ActiveCN103856980BCalibration is easyConnection managementRandom-access channelRadio Resource Control

Owner:HFI INNOVATION INC

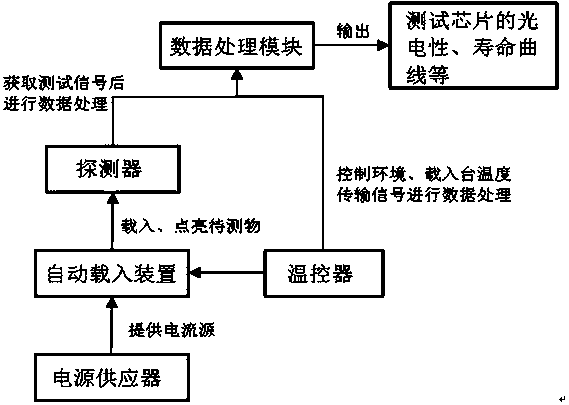

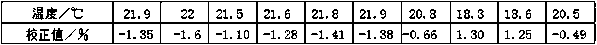

LED automatic life testing device and method

ActiveCN104808128BReduce the number of testsAvoid damageLamps testingIndividual semiconductor device testingComputer moduleLife testing

Owner:CHANGZHI CITY HUAJIE GUANG TECH CO LTD

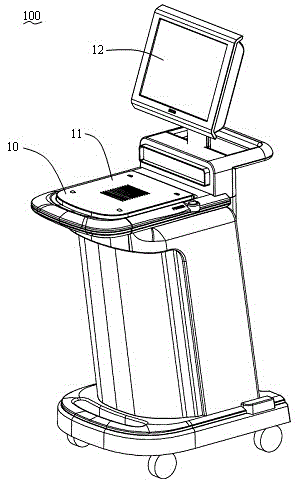

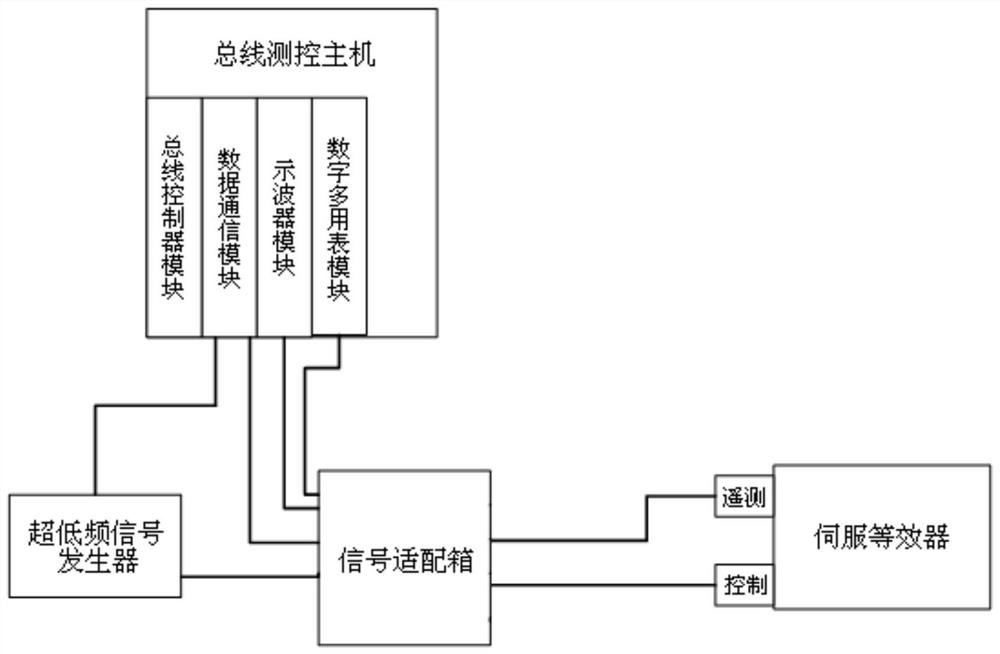

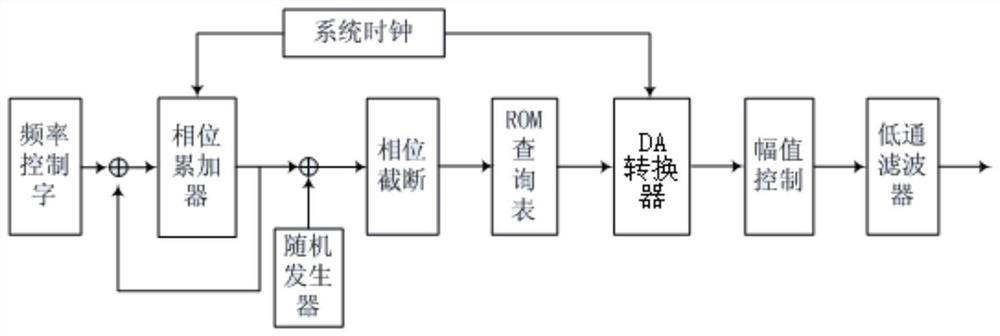

A Calibration System of Servo Equivalent

ActiveCN109901459BImprove performanceHigh precisionProgramme controlComputer controlControl engineeringBus mastering

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

Calibration method and system for gimbal

ActiveCN110553669BReduce manufacturing costCalibration is easyMeasurement devicesComputer hardwareTrunking

The invention discloses a pan-tilt calibration method and a calibration system. The method comprises: placing the pan-tilt to be calibrated on a horizontal calibration platform, and forming a communication connection with a relay module of the calibration platform; Follow the calibration instructions forwarded by the module, and perform pan-tilt calibration according to the received calibration instructions when the pan-tilt is still. In the present invention, the pan-tilt to be calibrated is placed on a horizontally set calibration platform, and forms a communication connection with the relay module of the calibration platform to receive the calibration instruction forwarded by the relay module to perform automatic calibration, without special fixtures, reducing The production cost is low, and the calibration operation is simple.

Owner:REMO TECH CO LTD

Headphone positioning fixture and rear end cover correction device

Owner:DONGGUAN WORLD PRECISION MACHINERY

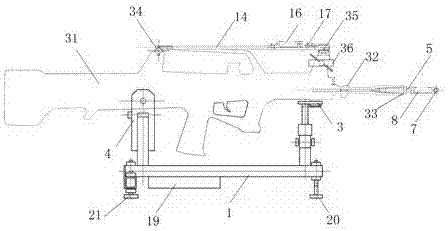

A gun level parallel correction device

InactiveCN105973070BCalibration is easyImprove operational efficiencySighting devicesEngineeringTransverse level

The invention provides gun level collimation equipment. The gun level collimation equipment comprises a gun horizontal adjustment support used for containing a gun, a gun inner bore bubble shaft used for adjusting a gun bore axis and a gun sight line bubble shaft used for adjusting a gun front sight. The gun inner bore bubble shaft comprises an inner bore cross groove elastic locating shaft, an inner bore shaft longitudinal bubble and an inner bore shaft transverse bubble, wherein the inner bore shaft longitudinal bubble and the inner bore shaft transverse bubble are located on the inner bore cross groove elastic locating shaft. The gun sight line bubble shaft comprises a sight line shaft, a sight line shaft longitudinal level bubble, a sight line shaft transverse level bubble and a front sight high-low support, wherein the sight line shaft longitudinal level bubble, the sight line shaft transverse level bubble and the front sight high-low support are arranged on the sight line shaft. By means of the equipment, gun correction operation is quite easy, batched correction operation is easy to implement and repeat, only the corresponding level bubbles need to be centered, aiming and ball firing do not need to be implemented, and errors caused by the individual difference of human eye aiming are avoided; the site is simplified, live shells are saved, and recovering and copying of the gun shooting accuracy can be carried out in batch; and the operation efficiency and safety of gun spotting are improved.

Owner:郭南南

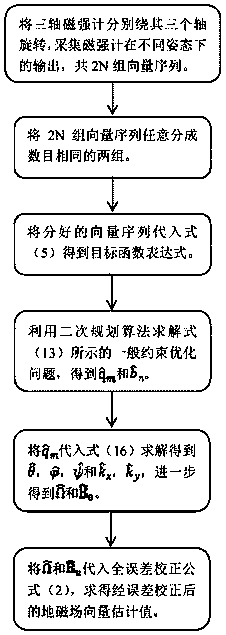

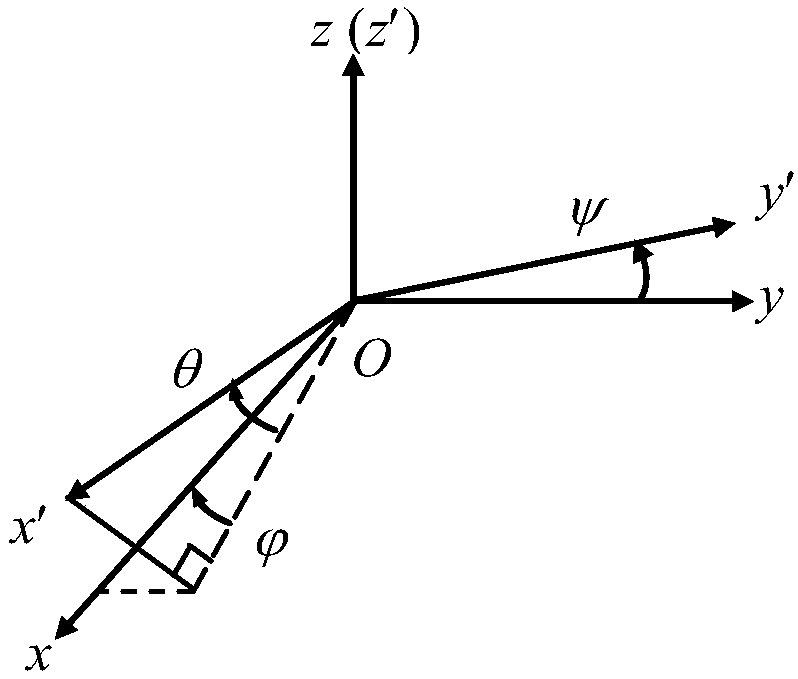

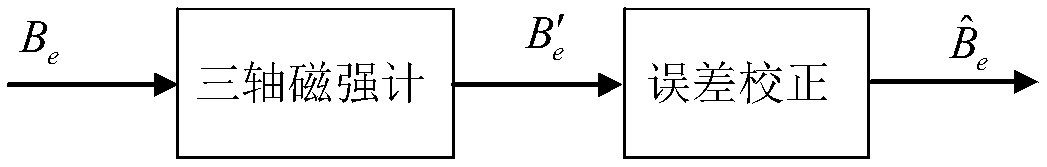

A Method for Identification and Correction of Total Error Parameters of Three-axis Magnetometers Independent of Geomagnetic Field Quantity

ActiveCN106125026BLow costAchieve simplicityElectrical measurementsGeological measurementsMeasurement deviceModular invariance

The invention provides a triaxial magnetometer total-error parameter identification and correction method independent from an earth magnetic field quantity. By use of modular invariance of an earth magnetic field, total-error parameters of a triaxial magnetometer are identified through earth magnetic field vector measurement data under different attitudes, based on this, an error corrector is constructed, total errors of the triaxial magnetometer are corrected by use of the constructed error corrector, and a detected magnetic field after correction is obtained. The method solves the problem of incapability total-error correction of the triaxial magnetometer due to incapability of identification of the total-error parameters of the triaxial magnetometer in the absence of the earth magnetic field quantity in the prior art; and at the same time, an additional earth magnetic field measurement device is unnecessary, and an additional attitude measurement device is also unnecessary for providing accurate external attitude information. The method further identifies all triaxial magnetometer errors, is high in identification precision, does not need auxiliary devices for measuring the earth magnetic field and the attitudes, simplifies the correction apparatus of the triaxial magnetometer and decreases the cost of a magnetic field measurement system.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com