Method for obtaining liquid level data from capacitance level transducer and device

A liquid level sensor, capacitive technology, applied in the field of liquid level sensors, can solve the problems of complex calibration operation and poor measurement accuracy, and achieve the effect of simple calibration operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

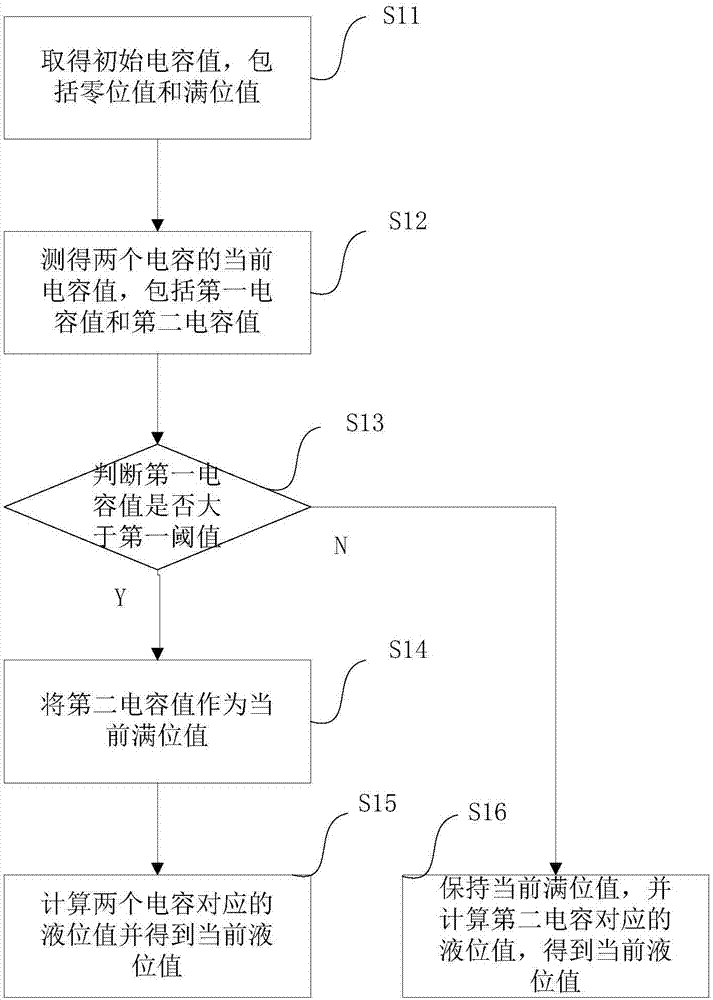

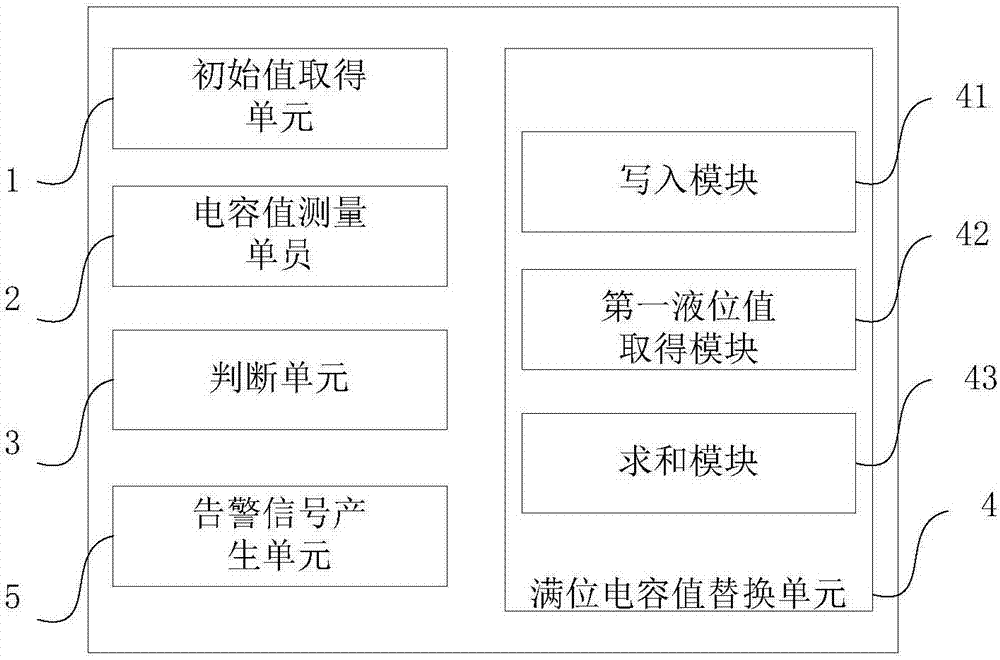

[0037] like figure 1 As shown, in a method and an embodiment of the device for obtaining liquid level data in a capacitive liquid level sensor of the present invention, the method includes the following steps:

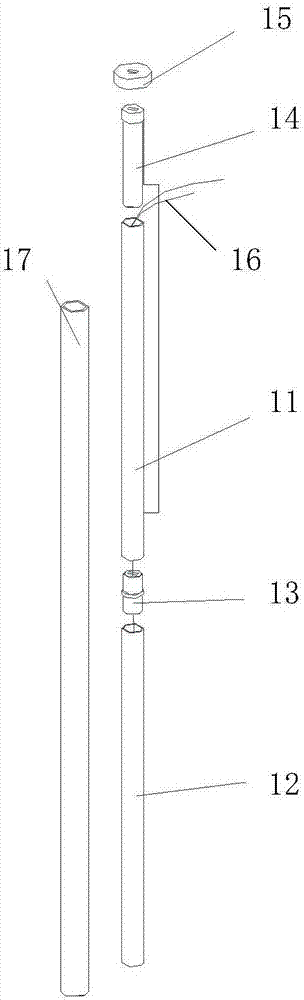

[0038] Step S11 obtains the initial capacitance value, including zero value and full value: In this embodiment, the method is applicable to a capacitive liquid level sensor with the following structure, the sensing part of the sensor has a concentric structure with the same The outer shell is used as an electrode, while the inner core is divided into two sections, and the two sections are connected together by a connector made of insulating material. The two sections have the same size and are used as lead-out wires respectively. One electrode on the two outer sides, so that the two sections of the inner core and the outer shell respectively for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com