Traceable calibration method and calibration device for dynamic characteristic of big pressure sensor

A technology of dynamic characteristics and calibration method, applied in the direction of calibration/testing of force/torque/power measuring instrument, measuring device, measuring fluid pressure, etc., to achieve the effect of high calibration pressure value, simple structure, and simple calibration operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1. Traceable calibration method and calibration device for dynamic characteristics of large pressure sensor

[0024]The traceable calibration method and calibration device for the dynamic characteristics of the large pressure sensor in this embodiment are divided into two parts, one is the traceable calibration device for the dynamic characteristics of the large pressure sensor; the other is the traceable calibration method for the dynamic characteristics of the large pressure sensor.

[0025] 1. Traceable calibration device for dynamic characteristics of large pressure sensors

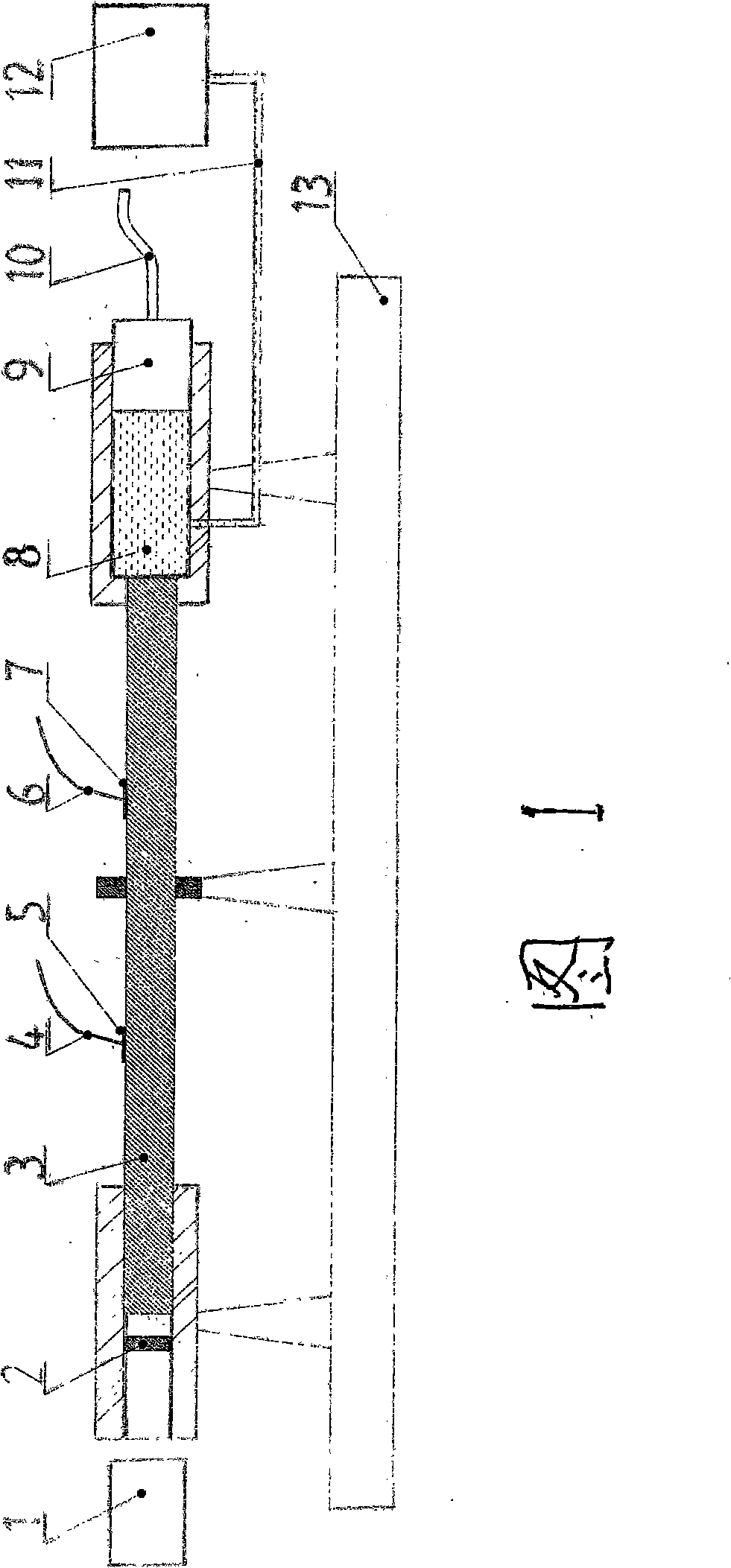

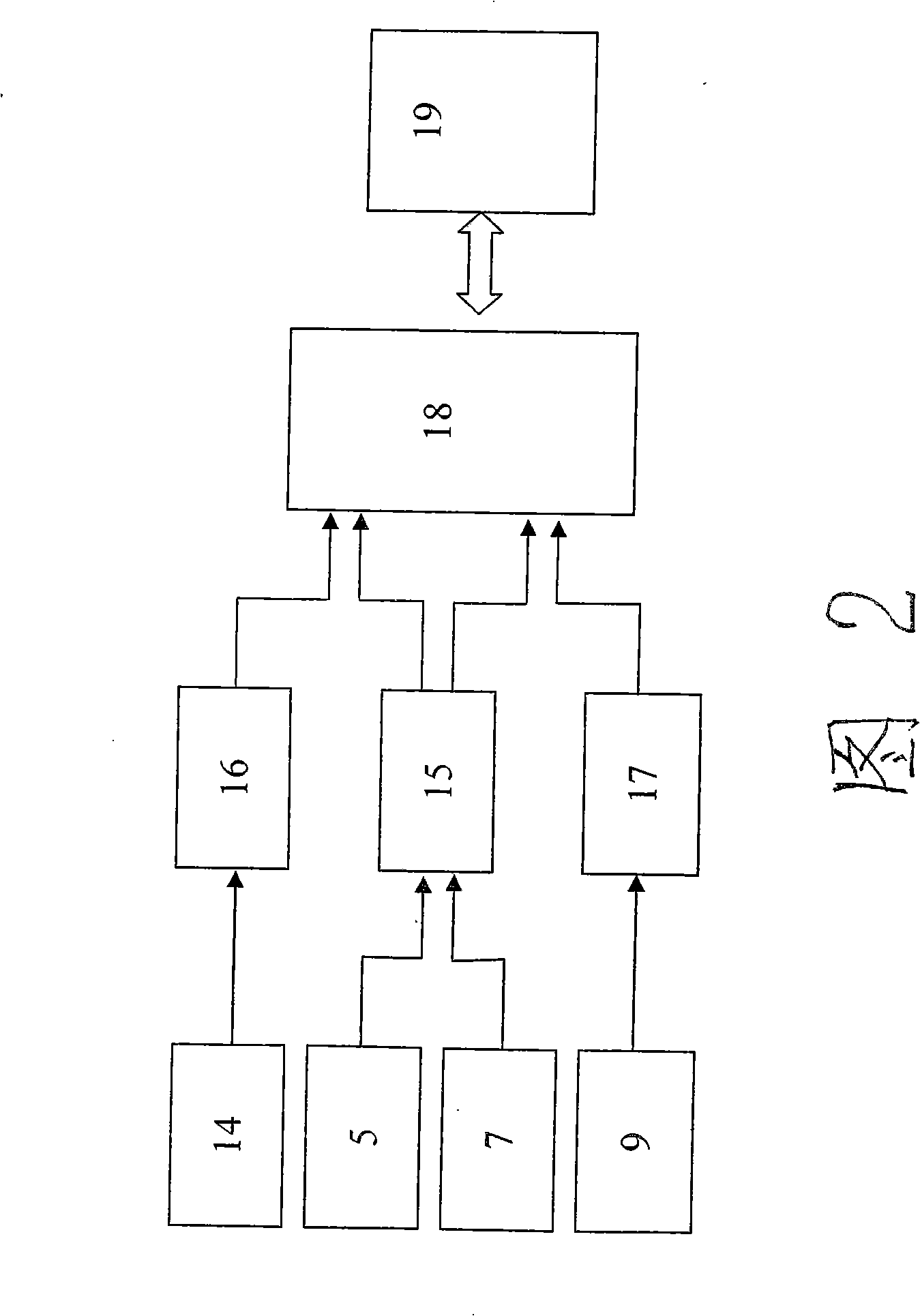

[0026] The specific structure of the traceable calibration device for the dynamic characteristics of the large pressure sensor in this example is shown in Figure 1, and Figure 2 shows the situation of some test instruments connected or connected with the calibration device in this example. This calibrating device comprises the housing of device and the support 13 of device, and the s...

Embodiment 2

[0029] Embodiment 2. Traceable calibration method and calibration device for dynamic characteristics of large pressure sensor

[0030] The traceable calibration method and calibration device for the dynamic characteristics of the large pressure sensor in this embodiment are divided into two parts:

[0031] 1. Traceable calibration device for dynamic characteristics of large pressure sensors

[0032] The specific structure of the traceable calibration device for the dynamic characteristics of the large pressure sensor in this example is shown in Figure 1, and Figure 2 shows the situation of some test instruments connected or connected with the calibration device in this example. The difference between the traceable calibration device of the dynamic characteristics of the large pressure sensor in this example and the embodiment 1.1 is as follows: 1. If a hydraulic calibration machine is used to apply a static pre-pressure to the calibrated large pressure sensor through the oil c...

Embodiment 3

[0035] Embodiment 3. Traceable calibration method and calibration device for dynamic characteristics of large pressure sensor

[0036] The traceable calibration method and calibration device for the dynamic characteristics of the large pressure sensor in this embodiment are divided into two parts:

[0037] 1. Traceable calibration device for dynamic characteristics of large pressure sensors

[0038] The specific structure of the traceable calibration device for the dynamic characteristics of the large pressure sensor in this example is shown in Figure 1, and Figure 2 shows the situation of some test instruments connected or connected with the calibration device in this example. The difference between the traceable calibration device for the dynamic characteristics of the large pressure sensor in this example and Embodiment 1.1. or Embodiment 2.1. are: 1. The traceable calibration device for the dynamic characteristics of the large pressure sensor in this example, and the adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com