Mounting correction tool for protection corner angle of frame column and manufacturing method thereof

A frame column and corner technology, which is applied in infrastructure engineering, architecture, building construction, etc., can solve the problems of inconvenient installation and correction method of frame column edge guard angle steel, difficult to ensure installation quality, time-consuming and troublesome, etc., to reduce operation. Procedure and labor intensity, ensure appearance quality, and correct the effect of intuitive operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

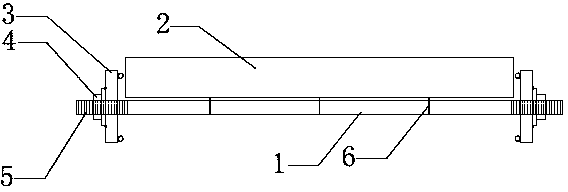

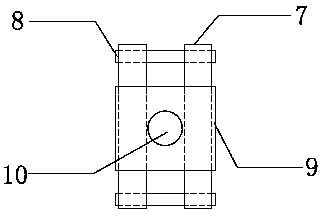

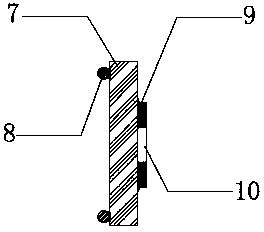

[0033] see now Figure 1 ~ Figure 3 , figure 1 It is a structural schematic diagram of installing a correction tool for the frame column edge protection angle steel of the present invention, figure 2 for figure 1 Enlarged front view of middle clip, image 3 for figure 2 side view. As shown in the figure, the screw rod 1 is a screw rod made of a round steel with a diameter of 14mm, and its length is 200mm longer than the section size of the installed frame column. The two ends of the screw rod are provided with threads and are equipped with fixing nuts 4, wherein There are several small holes that allow iron nails 6 to pass through the internal drill;

[0034] The length of the wooden side 2 is 5mm longer than the installed frame column section size, and it is connected and fixed with the screw rod 1 through the aperture of the screw rod 1 passed by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com