Chassis engine power takeoff short arm support concrete pump truck

The technology of a concrete pump truck and engine is applied in the direction of mechanical equipment, building material processing, fluid pressure actuating device, etc., which can solve the problems of inconvenient production enterprises, complex structure, inconvenient maintenance and maintenance, etc., and achieve long cycle, Effect of cost reduction and high procurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

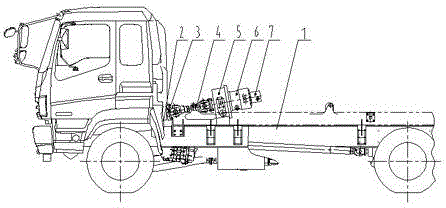

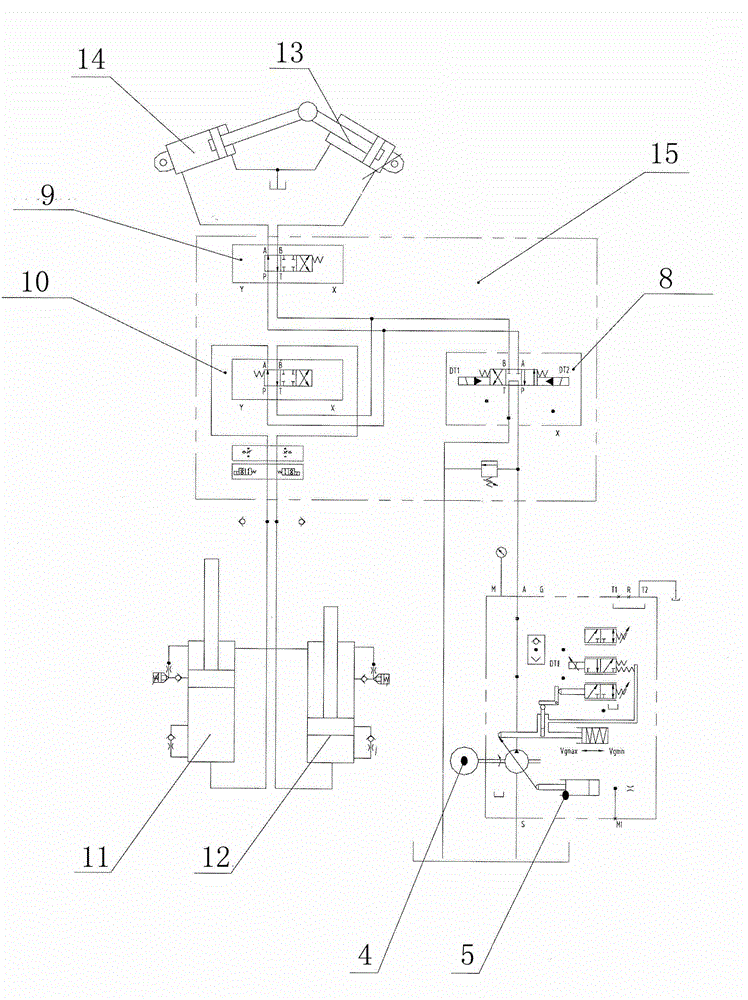

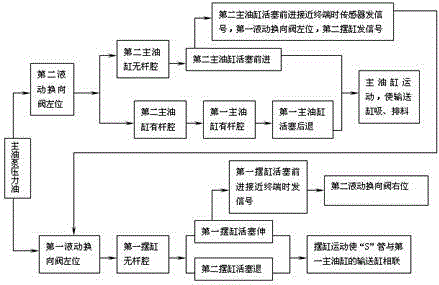

[0012] A short-boom concrete pump truck with power taken from the chassis engine, refer to figure 1 , figure 2 , an engine 2 is provided on the chassis 1 of the pump truck, a power take-off 3 is provided on the engine 2, one end of the transmission shaft 4 is connected to the power take-off 3, one end of the transmission shaft 4 is connected to the power take-off 3, and the other end is connected to the string The main oil pump 5, the boom pump 6 and the stirring, washing and cooling pump 7 connected together, the main oil pump 5 is connected to control the first main oil cylinder 11, the second main oil cylinder 12, the first swing cylinder 13 and the second main oil cylinder through the main valve block 15 Two swing cylinders 14, boom pump 6 and stirring, washing and cooling pumps 7 are respectively connected to control corresponding systems.

[0013] The main valve block 15 is connected to the first hydraulic reversing valve 9 and the second hydraulic reversing valve 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com