Capacity-variable trolley resistance furnace

A trolley-type resistance furnace, a variable technology, applied in the furnace, furnace type, lighting and heating equipment, etc., can solve the problems of poor temperature uniformity of the inner wall of the furnace, low availability, heat waste, etc., to achieve space availability. High, small size, good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

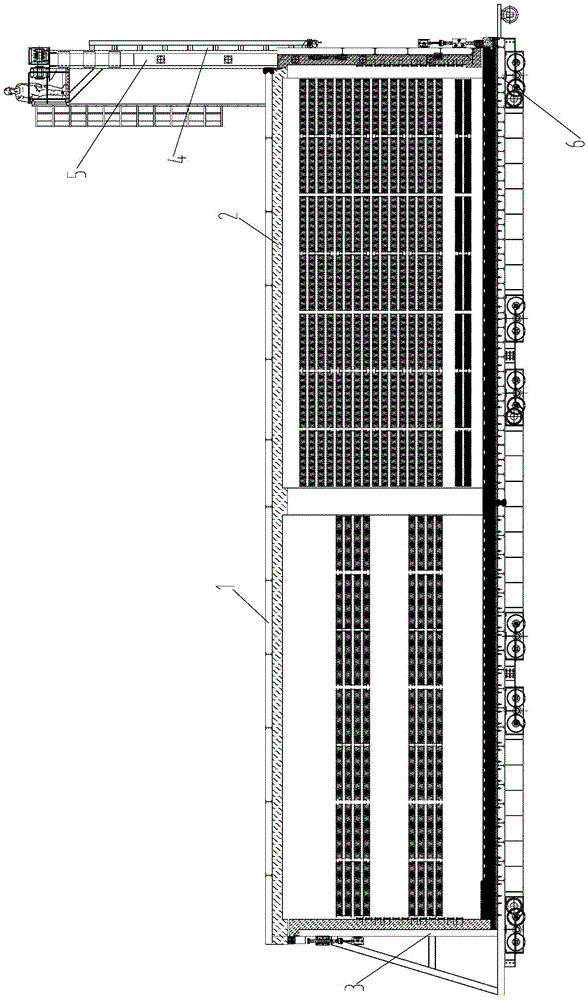

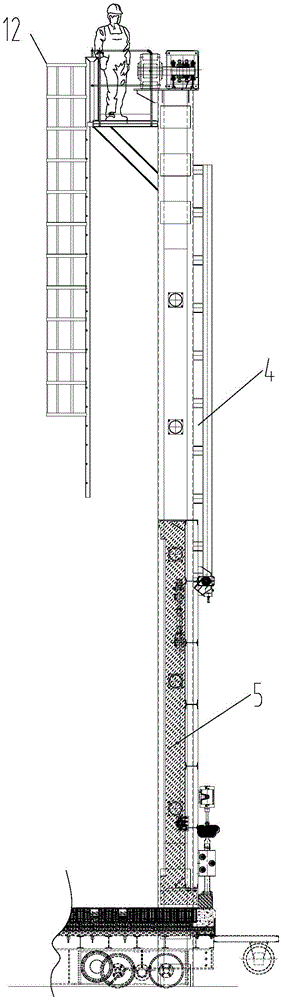

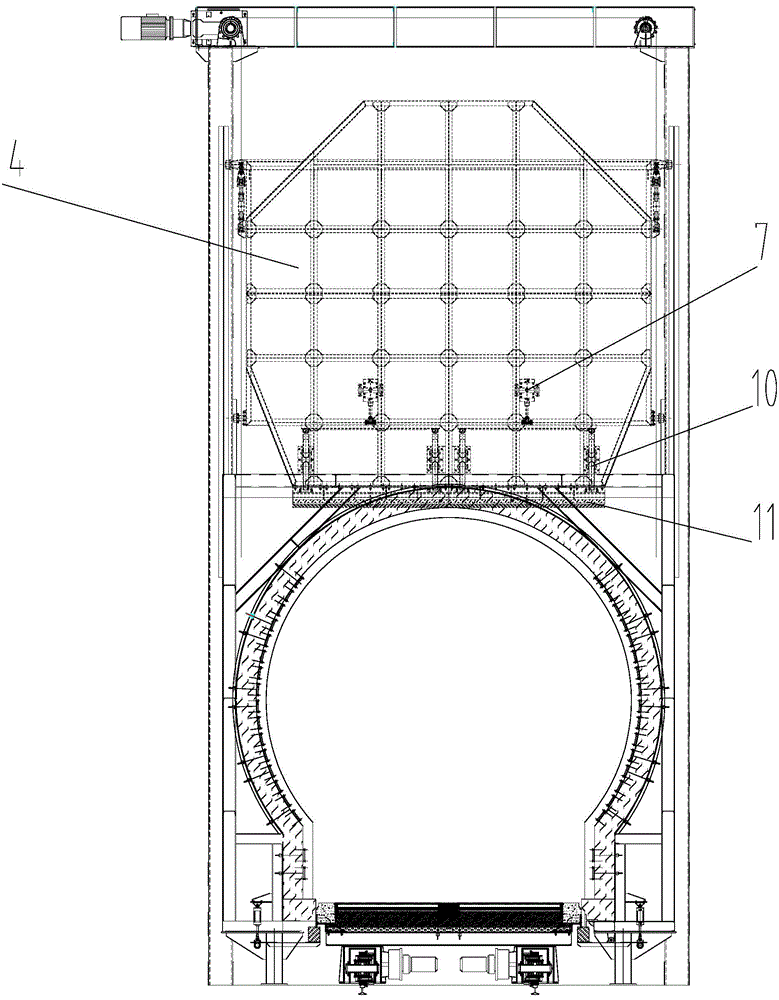

[0024] Example 1, such as figure 1 , as shown in 2 and 5, this embodiment discloses a variable-capacity trolley-type resistance furnace, including a furnace body 1, and a furnace 2 for accommodating the trolley inside the furnace body 1. The improvement is that the platform One end of the car 6 is provided with a rear furnace door 3, and the end of the furnace body 1 away from the rear furnace door 3 is provided with a front furnace door 4 and a front furnace door lifting mechanism 5; wherein there is a gap between the rear furnace door 3 and the inner wall of the furnace, and the rear Several push rods 9 are arranged on the furnace door, and a sealing block 8 is installed on the top of each push rod 7, and the gap can be sealed by the sealing block 8 after starting the push rod 9.

[0025] In this embodiment, the cross-sectional shape of the furnace in the vertical direction is a door-hole shape.

[0026] In this embodiment, the gap between the rear furnace door and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com