Measuring ruler for quality inspection of garment sewing process

A quality inspection and process technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of inability to intuitively judge whether the measurement results meet the preset standards, low quality inspection efficiency, cumbersome process, etc., to achieve Improve the efficiency of quality inspection, easy to carry, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

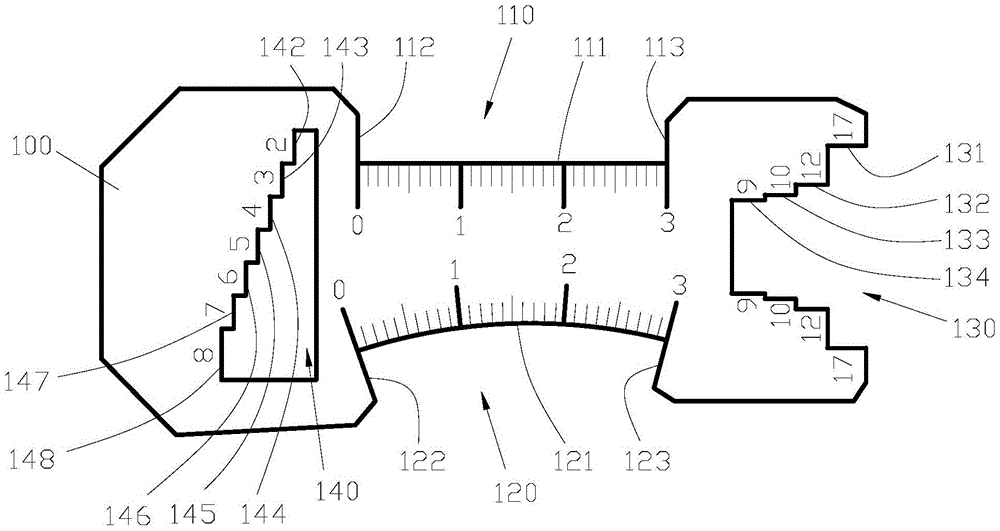

[0023] see figure 1 , a special measuring ruler for quality inspection of garment sewing process, comprising a bottom plate 100, the bottom plate 100 can be made of transparent plastic. The base plate 100 is provided with: a first notch 110 for measuring the stitch distance of a straight suture, a second notch 120 for measuring the stitch distance of an arcuate suture, and a notch 120 for measuring the width of the bundle after sewing. The third notch 130, and the hollow 140 for measuring the height of the triangular needle suture.

[0024] The first notch 110 has a straight line measuring base 111, and a left side 112 and a right side 113 respectively positioned at two ends of the straight line measuring base 111, the left side 112 and the right side 113 are all aligned with the straight line measuring base 111 vertical. The length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com