Device and method for preparing true triaxial remolded sample by utilizing vacuum preloading

A true triaxial and vacuum technology, which is applied in the field of devices for preparing true triaxial reshaped samples by vacuum pre-pressing, can solve the problem of easy formation of spring soil, uneven moisture content and density of samples, and uneven moisture content and density of samples. problems of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

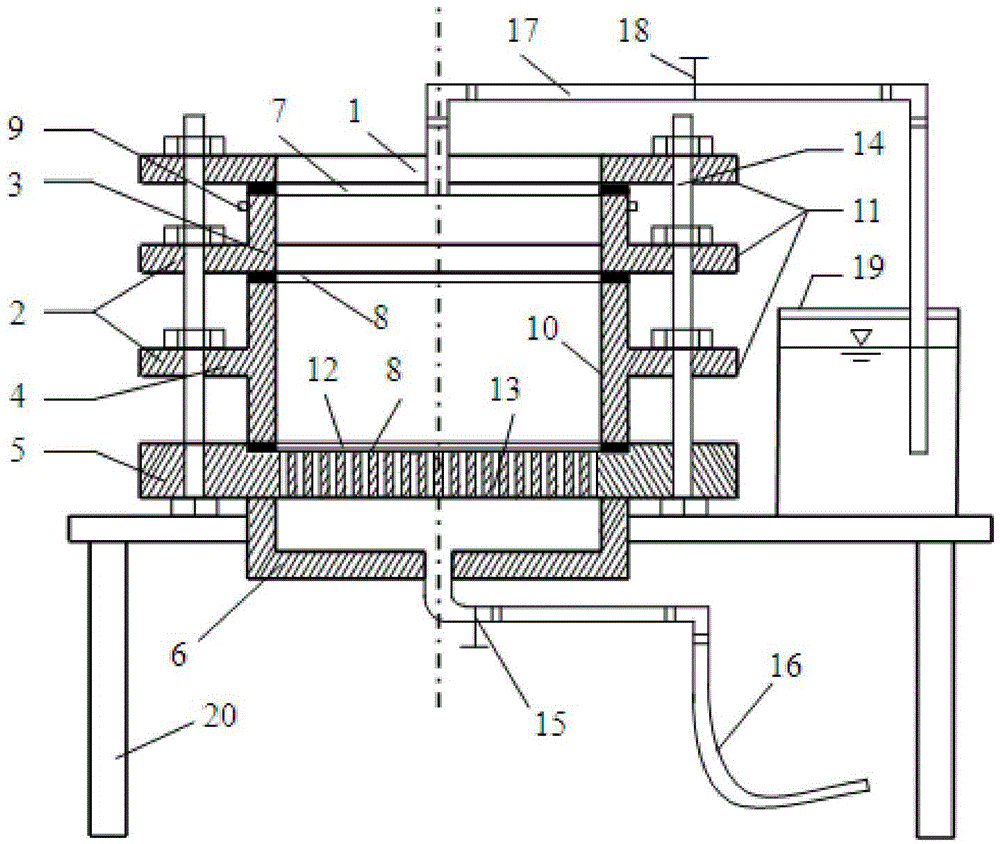

[0029] The present invention will be further introduced below in conjunction with the accompanying drawings.

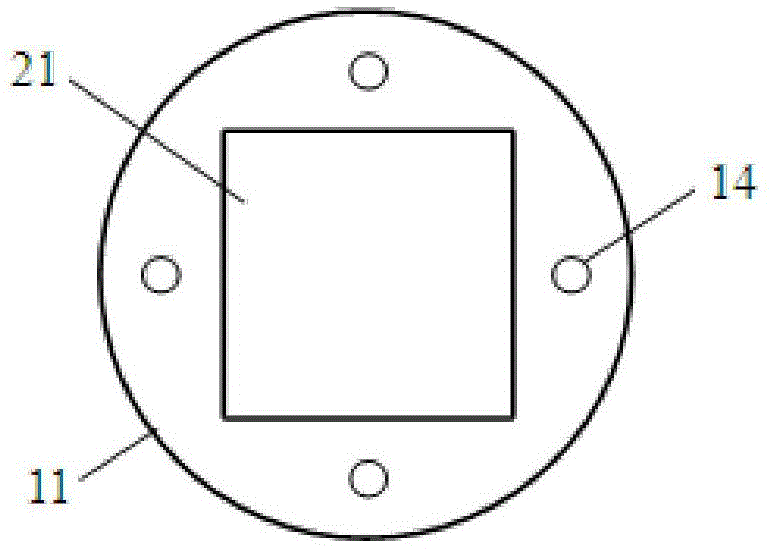

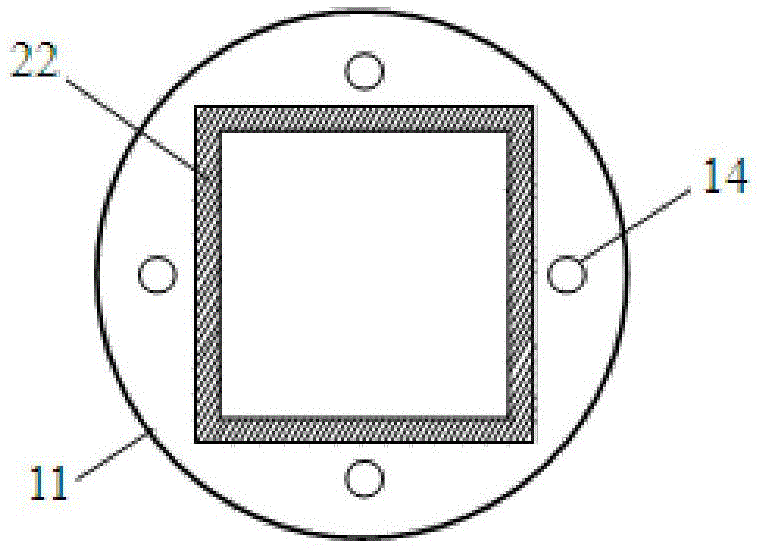

[0030] as attached figure 1 , figure 2 , image 3 and Figure 4 As shown, a device and method for preparing a true triaxial remodeling sample by vacuum preloading according to the present invention includes a sealed top cover 1, a sample preparation frame 2 (including a reserved layer frame 3 and a sample frame 4) , drainage base 5 and saturation device (water suction pipe 17, water stop valve 18, glassware 19) and other main components, as well as rubber membrane 7, rubber sealing washer 8, rubber band 9, plastic wrap 10, filter paper 12, bolt 14, drainage Supporting parts such as valve 15 and drainpipe 16. The sealing top cover 1 is made of a rectangular hollow flange 11; the sample preparation frame 2 is composed of a flange 11 and a rectangular frame 22, which includes a reserved layer frame 3 and a sample frame 4; the drainage base 5 is made of a solid flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com