Production plan management system and method

A production management system and production planning technology, applied in the computer field, can solve the problems of unfavorable and backward organization of production, and inconvenient management of manual account data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

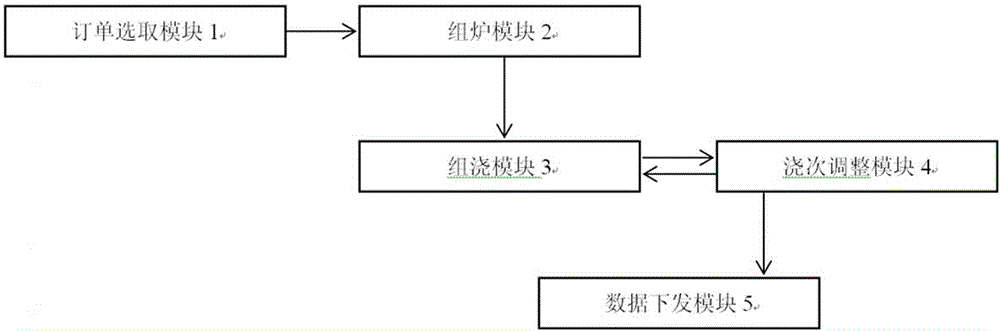

[0019] The production plan management system is characterized in that it includes a compilation module, an adjustment module, and a distribution module, wherein:

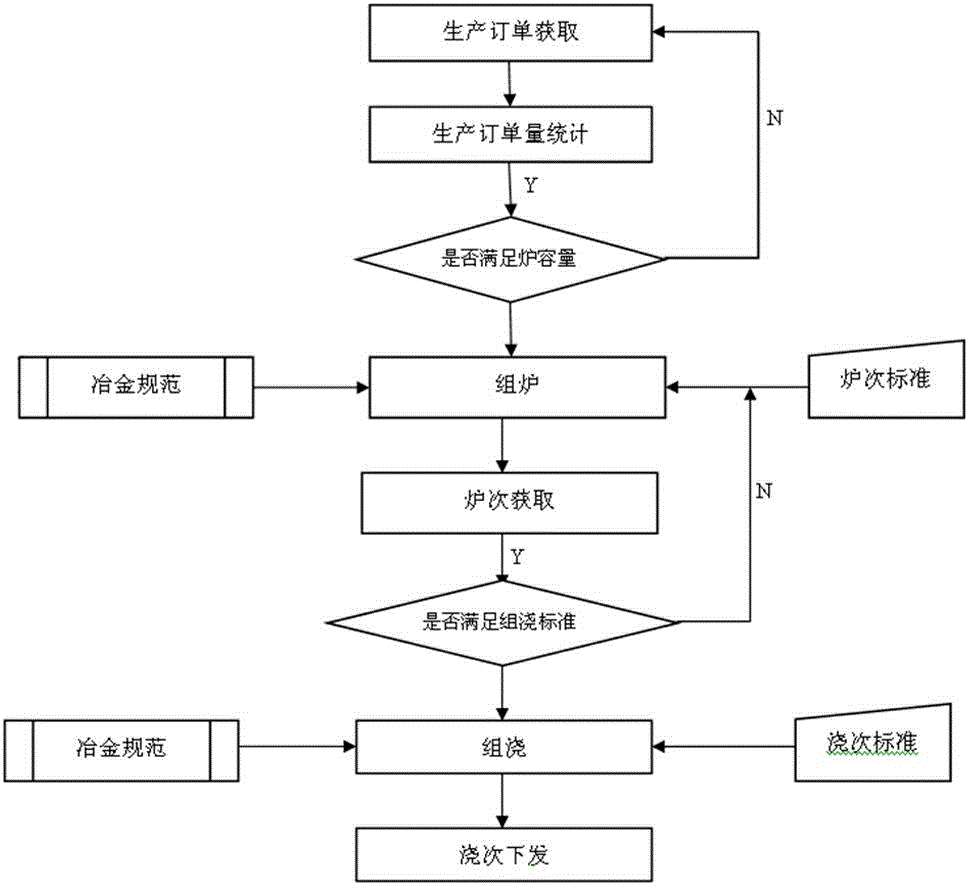

[0020] Compilation module: used to combine orders to form a plan according to the principle of furnace grouping according to the designed billet information;

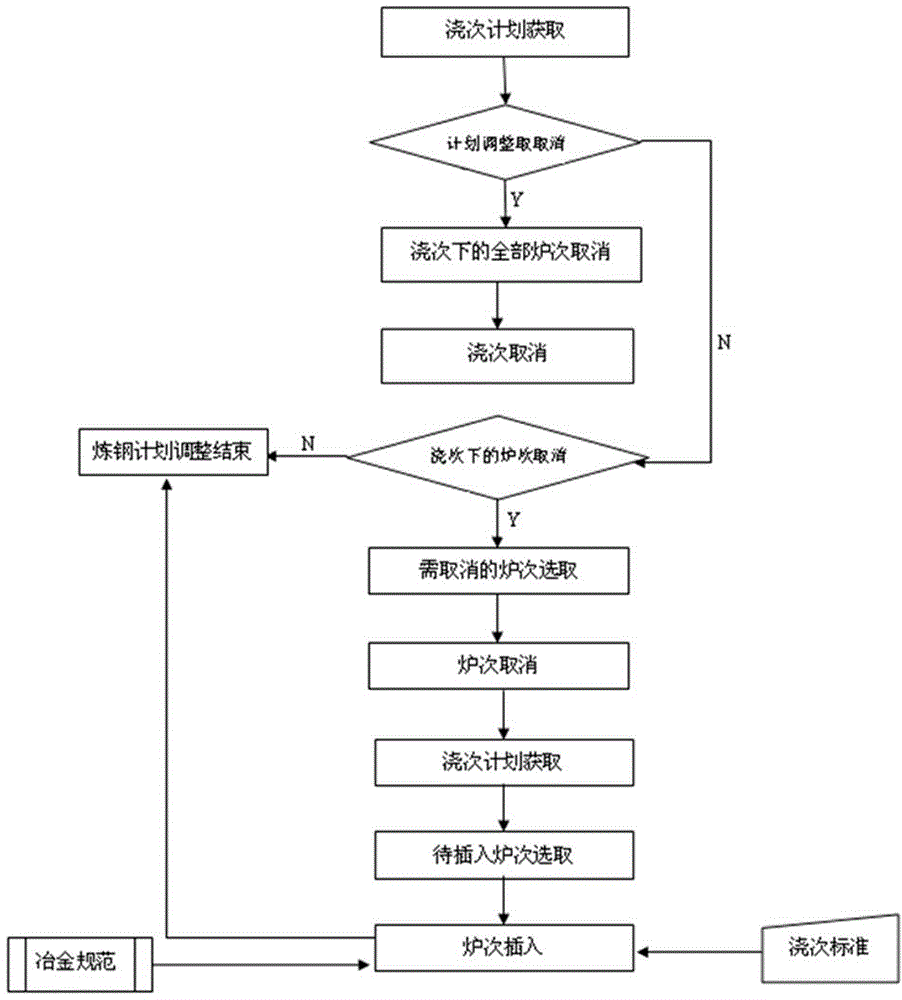

[0021] Adjustment module: used to adjust the plan in time according to the production information;

[0022] Delivery module: used to confirm the prepared planning information one by one, and issue it to guide production.

[0023] The blank information described in the compilation module is the grade, section specification, length, standard number and whether it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com